Discovering the intricacies of cutting-edge polymer materials involves delving deep into their specifications and properties, unraveling the mysteries of their composition and performance. In this segment, we embark on an expedition into the realm of innovative synthetic compounds, navigating through technical intricacies and uncovering the unique characteristics that set them apart in the industrial landscape.

Exploring the realm of high-performance polymers requires a keen eye for detail and an understanding of the nuanced terminology that defines their capabilities. Within the vast array of synthetic materials available, certain formulations stand out for their exceptional properties and diverse applications. By delving into the datasheets of these remarkable compounds, we unearth insights into their mechanical strength, chemical resistance, and thermal stability, illuminating their potential in various engineering disciplines.

Embark on a journey through the realm of advanced polymer specifications, where each datasheet serves as a roadmap to understanding the intricate balance of properties that define these synthetic wonders. Join us as we decode the language of materials science and uncover the hidden potential of cutting-edge polymers, paving the way for innovation and advancement in diverse industries.

Understanding Properties and Applications of a Prominent Polymer

In this section, we delve into the myriad characteristics and practical uses of a widely recognized thermoplastic material. Exploring its diverse attributes and real-world applications unveils the versatility and significance of this polymer.

The Versatile Nature of the Material

This polymer boasts a broad spectrum of properties, ranging from mechanical strength to chemical resistance, rendering it suitable for an array of applications across various industries. Its adaptability and resilience make it a favored choice in engineering and manufacturing.

Practical Implementations Across Industries

From automotive components to consumer goods, this material finds its way into numerous products, enhancing performance and durability. Its ability to withstand harsh environments and maintain structural integrity makes it indispensable in modern manufacturing processes.

Exploring the realm of this polymer reveals a rich tapestry of attributes and applications, underscoring its pivotal role in contemporary industry.

Exploring the Mechanical Strength and Durability

In this section, we delve into the robustness and resilience of the material, focusing on its ability to withstand various forces and maintain structural integrity over time. We examine how the substance responds to external pressures, impacts, and environmental factors without compromising its functionality.

To begin our exploration, we assess the material’s resistance to mechanical stress, evaluating its capacity to endure tension, compression, bending, and torsion. We investigate how the substance performs under different loading conditions, considering factors such as deformation, elasticity, and yield strength.

Furthermore, we analyze the material’s durability, investigating its longevity and resistance to wear, abrasion, and fatigue. We examine how the substance holds up over repeated use and exposure to harsh conditions, highlighting its ability to maintain performance over extended periods.

Moreover, we explore the material’s ability to withstand environmental factors such as temperature variations, humidity, and chemical exposure. We investigate how these external elements affect the material’s mechanical properties and longevity, shedding light on its suitability for various applications.

Throughout this section, we aim to provide a comprehensive understanding of the material’s mechanical strength and durability, highlighting its potential for diverse industrial and engineering applications.

Chemical Resistance and Thermal Stability

In this section, we delve into the robustness of the material in the face of various chemical agents and its ability to withstand high temperatures. Understanding how the material interacts with different substances and its behavior under varying thermal conditions is crucial for ensuring its reliability and performance in diverse applications.

Chemical Resistance

The material’s resistance to chemical substances plays a pivotal role in determining its suitability for specific environments and applications. We explore how the material fares against a spectrum of chemicals, ranging from corrosive liquids to solvents, without compromising its structural integrity or functional properties. Evaluating its chemical inertness and resilience empowers engineers and designers to make informed decisions regarding material selection for their projects.

Thermal Stability

Thermal stability encompasses the material’s ability to maintain its structural integrity and performance under elevated temperatures. We investigate how the material responds to heat exposure, examining its dimensional stability, mechanical strength, and other pertinent properties. Understanding its thermal behavior aids in predicting its performance in applications subjected to high temperatures, ensuring longevity and reliability.

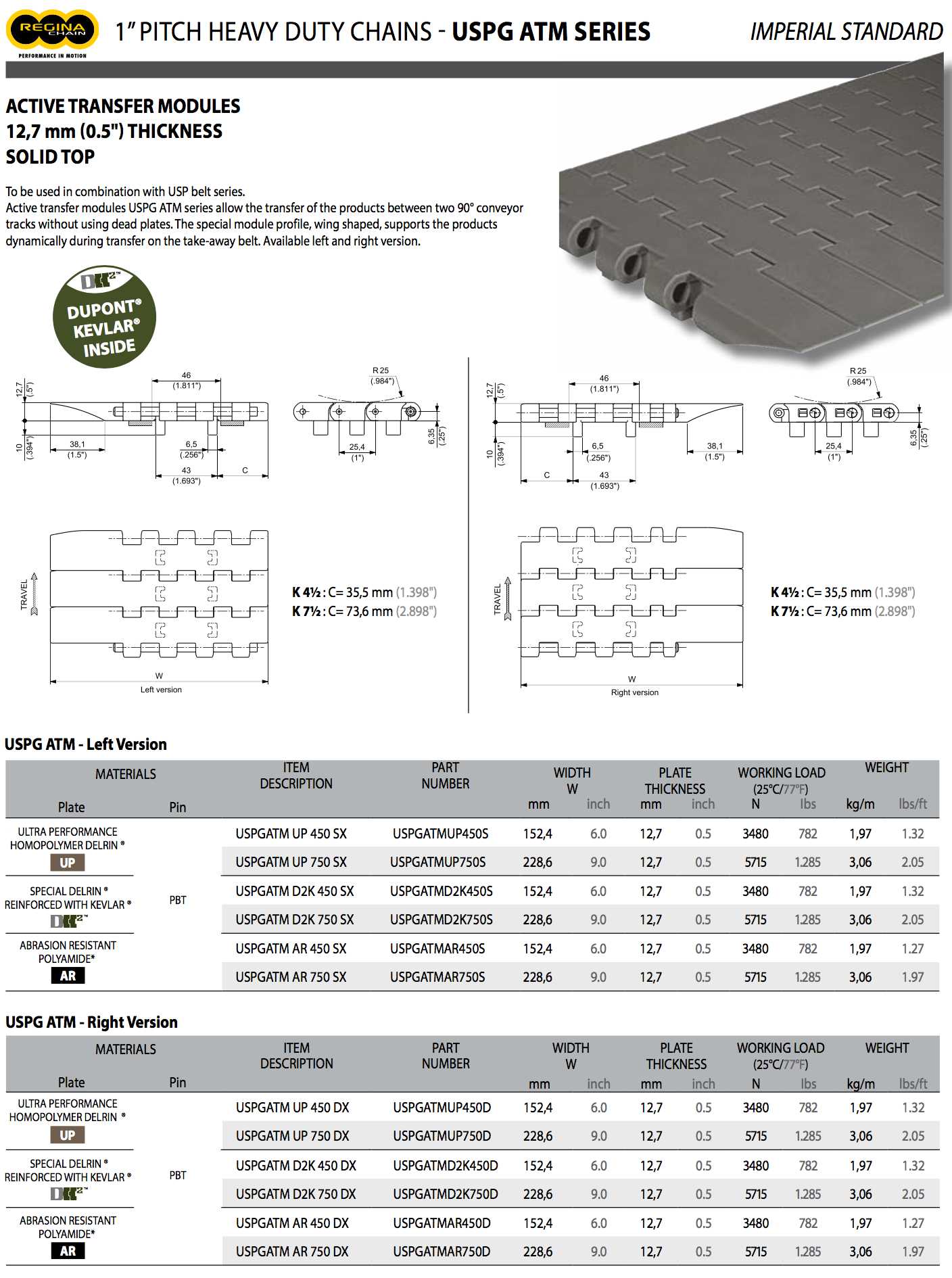

Practical Applications and Engineering Solutions

In this section, we explore real-world scenarios where innovative engineering approaches meet practical challenges, leveraging the versatile properties and capabilities inherent in advanced polymer materials. From enhancing structural integrity to optimizing manufacturing processes, these applications illustrate the ingenuity and adaptability of modern engineering solutions.

Structural Reinforcement in Automotive Design

Within the realm of automotive engineering, the quest for lightweight yet durable materials is ever-present. Engineers continually seek solutions to improve fuel efficiency without compromising safety or performance. Through the utilization of high-performance polymers with exceptional strength-to-weight ratios, vehicles can achieve greater structural integrity while minimizing overall weight, resulting in enhanced fuel economy and reduced environmental impact.

Streamlining Manufacturing Processes in Consumer Electronics

Consumer electronics represent a dynamic and fast-paced industry where efficiency and precision are paramount. From smartphones to home appliances, the demand for sleek, lightweight, and durable products drives innovation in manufacturing techniques. Advanced polymer materials offer engineers the flexibility to design intricate components with intricate geometries, facilitating streamlined production processes and shorter time-to-market cycles. By harnessing the unique properties of these materials, manufacturers can achieve greater cost-effectiveness and product reliability.