Within the realm of industrial engineering, a dynamic and thriving sector characterized by constant innovation, experts in the field are always on the lookout for pioneering technologies that can revolutionize systems and enhance operational efficiency to unprecedented levels. In this pursuit, one particular device emerges as a game-changer, offering unparalleled control and precision in the management of fluid flow. This article delves into the intricacies of a remarkable and indispensable component, adeptly designed to optimize flow regulation while ensuring utmost safety and reliability.

An embodiment of engineering excellence, this highly sophisticated apparatus discreetly governs the movement of fluids through its intuitive design and meticulously crafted mechanics. This ingenious solution not only offers an exceptional flow control mechanism, but it also boasts an impressive range of features that position it as an invaluable asset for a myriad of industries. Be it large-scale oil and gas operations, high-pressure chemical processing units, or even critical nuclear facilities, this labyrinthine contraption brings forth immense benefits and exhibits an unwavering commitment to precision.

As an astute observer delves deep into the functionality and intricate inner workings of this marvel, they are immediately astounded by the remarkable simplicity that belies its unparalleled power. By restricting the flow of fluid through its intricate channels and apertures, the device seamlessly adjusts to varying process conditions, magnifying its scope and versatility. The labyrinth of passages, akin to the intricate neural pathways of the human brain, synergistically enable an influx of advantages that empower precision engineers and system operators alike.

The journey through the core yet elusive understanding of this awe-inspiring innovation would be incomplete without acknowledging the diligent efforts invested in its design and development. A culmination of boundless ingenuity and extensive research, this extraordinary piece of engineering stands triumphantly as a testament to the pursuit of excellence and unwavering commitment to safety. The reliability and robustness of the device are manifest through its meticulous testing and continuous refinement, ensuring the utmost dependability and imperviousness to the unpredictable forces of the industry.

What is a Master Flo Choke Valve?

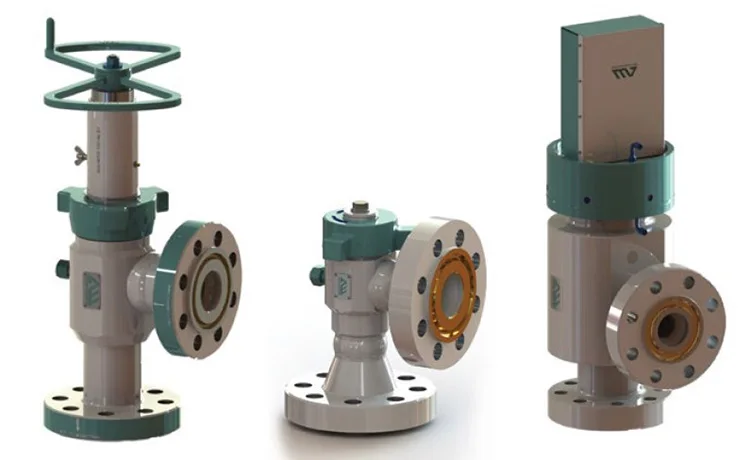

A Master Flo Choke Valve, also commonly known as a flow restriction device, is a technological solution used in various industries to regulate and control the flow of fluids or gases. It is a critical component in systems where precise control of flow rates is required to optimize operations, enhance safety, and achieve desired outcomes.

The Function of a Choke Valve

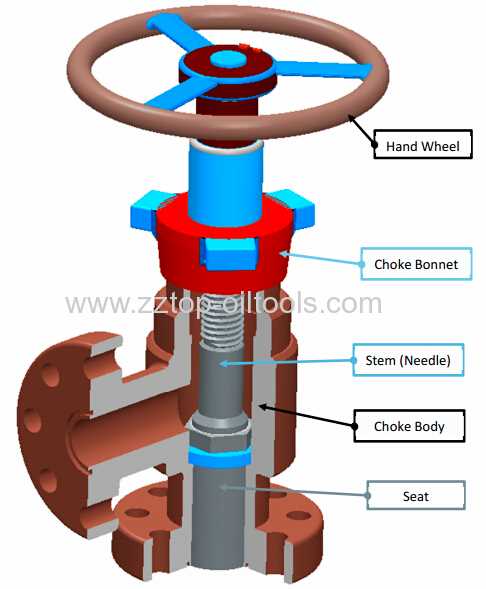

A choke valve operates on the principle of restricting or obstructing the flow of fluid or gas through a specific channel or passage. By adjusting the degree of restriction, it effectively controls the flow rate and pressure within a system. This precision control is crucial for applications such as production wells, pipelines, and other fluid handling systems.

Applications of Choke Valves

Choke valves find extensive use in various industries, including oil and gas, petrochemicals, mining, and power generation. They are commonly employed in wellhead production, where they help in managing pressure, preventing surges, and regulating the flow of hydrocarbons from reservoirs. Additionally, choke valves are used in pipelines to control the flow rate, maintain stability, and prevent damage due to excessive pressure or flow velocities.

- Oil and Gas Industry: Choke valves are vital for efficient production and safety in exploration, drilling, and well intervention processes.

- Petrochemical Industry: Choke valves play a crucial role in controlling the flow of chemicals and gases in refining and processing operations.

- Mining Industry: Choke valves are used in ore processing plants to manage the flow of slurries and fluids.

- Power Generation: Choke valves assist in regulating steam flow and pressure in steam turbines, ensuring optimal efficiency.

In conclusion, a Master Flo Choke Valve is an indispensable component in various industries that enables precise control of fluid or gas flow rates. It plays a vital role in enhancing operational efficiency, maintaining safety, and achieving optimal performance in diverse applications.

Importance of Master Flo Choke Valve Datasheet

Understanding the significance of a comprehensive technical document is crucial when it comes to the Master Flo Choke Valve equipment. This information-packed datasheet plays a vital role in providing crucial details and specifications about the valve, allowing engineers and operators to make informed decisions.

1. Comprehensive Overview: A well-prepared datasheet offers a detailed insight into the functionalities and capabilities of the Master Flo Choke Valve. It provides a comprehensive overview of the valve’s design, technical specifications, and performance characteristics.

2. Technical Specifications: The datasheet presents essential technical information, including dimensions, materials used, pressure ratings, temperature range, flow capacity, and fluid compatibility. These specifications are vital for engineers to ensure proper valve selection and integration within the system.

3. Performance Data: The performance data outlined in the datasheet allows operators to assess how the Master Flo Choke Valve will perform under different operating conditions. It provides critical details about the valve’s flow control capabilities, pressure drop characteristics, and overall efficiency.

4. Application Considerations: The datasheet aids in understanding the various applications for which the Master Flo Choke Valve is suitable. It highlights the valve’s adaptability to different industries, such as oil and gas, refining, petrochemical, and power generation.

5. Safety and Reliability: The datasheet often includes information about the valve’s safety features, certifications, and compliance with industry standards. It helps users evaluate the valve’s reliability, durability, and ability to withstand demanding operating conditions.

6. Maintenance and Troubleshooting: The datasheet provides valuable insights into maintenance requirements, recommended spare parts, and troubleshooting guidelines. It enables operators to effectively manage and maintain the Master Flo Choke Valve, ensuring optimal performance and longevity.

In summary, having access to a well-structured Master Flo Choke Valve datasheet is of utmost importance. It offers a wealth of information that aids decision-making, enhances the valve’s integration, and increases operational efficiency.