Technological advancements have propelled us into an era where innovation and efficiency reign supreme. In today’s rapidly evolving world, industries rely heavily on cutting-edge devices to enhance productivity and streamline operations. Among these remarkable tools, the 1769-IQ16 stands tall as a game-changer that revolutionizes data acquisition and analysis like never before.

The 1769-IQ16, renowned for its unparalleled performance and reliability, serves as an indispensable component in various industrial processes. This remarkable device empowers users with the ability to gather critical information, monitor system conditions, and make informed decisions that drive business success. With its exceptional precision and accuracy, the 1769-IQ16 takes sensor integration to new heights, building a foundation for optimization and synchronization across multiple systems.

Incorporating state-of-the-art technology, the 1769-IQ16 ensures seamless connectivity and real-time data acquisition. This intelligent device allows for seamless integration with existing systems, facilitating effortless information exchange and synchronization. Equipped with advanced features, such as high-speed processing and memory capabilities, the 1769-IQ16 offers an expansive range of possibilities for automation and process control.

With the aim of providing users with an unparalleled experience, the 1769-IQ16 boasts a user-friendly interface, enabling effortless configuration and customization. Its intuitive design makes it accessible to both novice and expert users alike, empowering them to harness the full potential of this remarkable device. The 1769-IQ16 is not just a mere data acquisition tool; it is a catalyst for innovation, ensuring organizations stay at the forefront of the ever-evolving industrial landscape.

Understanding the Features of the 1769-IQ16 Datasheet

In this section, we will explore the various functionalities and capabilities showcased in the datasheet of the 1769-IQ16 module. By analyzing its inherent features, we can gain a comprehensive understanding of its potential applications and advantages.

The 1769-IQ16 datasheet elucidates the multitude of functionalities and features that make this module an essential component in various industrial automation systems. Through a detailed exploration, we can uncover its proficiency in facilitating quick and accurate digital input capabilities, enabling seamless integration into complex systems.

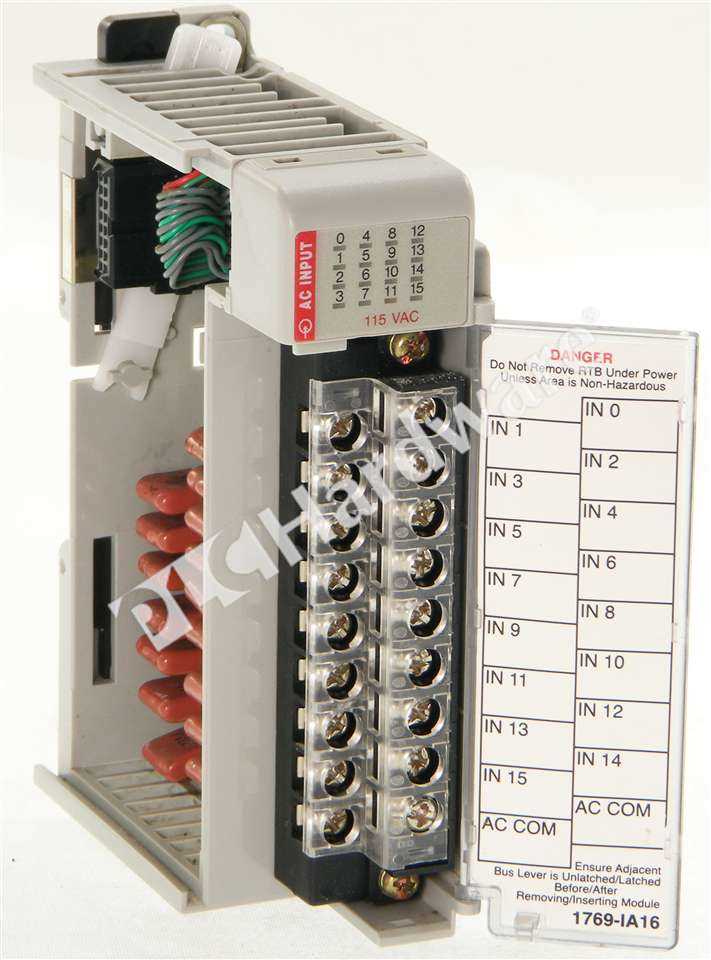

One of the significant features highlighted in the datasheet is the high-density input design, which allows the module to accommodate numerous digital input signals simultaneously. This capability ensures efficient data acquisition from a wide range of sources, enhancing the module’s versatility in diverse industrial applications.

Furthermore, the 1769-IQ16 module is equipped with robust signal filtering capabilities, enabling reliable operation even in noisy environments. This feature mitigates the impact of external electrical interference, ensuring accurate and consistent digital input readings for precise control and monitoring.

Another notable aspect highlighted in the datasheet is the module’s compact and space-saving design. With its slim form factor, the 1769-IQ16 module can be effortlessly integrated into space-constrained industrial setups, maximizing available workspace without compromising on performance or functionality.

Add to that, the 1769-IQ16 module boasts high-speed data transmission and response times, facilitating rapid communication and real-time data updates. This capability enables prompt decision-making, optimizing operational efficiency and enhancing overall system performance.

Moreover, the datasheet emphasizes the module’s reliable and robust construction, ensuring long-term durability and resistance to harsh environmental conditions. This factor extends the module’s lifespan and enhances its suitability for use in demanding industrial environments.

Overall, the 1769-IQ16 datasheet provides a comprehensive overview of the module’s extensive features and capabilities. By carefully examining these details, stakeholders can make informed decisions regarding the module’s integration into their specific automation systems, ensuring enhanced productivity, reliability, and operational efficiency.

A Comprehensive Overview of the Key Specifications

In this section, we will provide an in-depth analysis of the essential specifications of the 1769-iq16 module. By understanding these key characteristics, users can make informed decisions regarding its suitability for their specific application.

Input Channels

The 1769-iq16 module offers a versatile array of input channels, each capable of handling a wide range of signals. These channels are designed to accommodate various input types, allowing for seamless integration with different devices and systems. Additionally, the module provides advanced signal conditioning capabilities, ensuring accurate and reliable input readings.

Data Processing Capabilities

Equipped with powerful data processing capabilities, the 1769-iq16 module can handle complex calculations, making it ideal for applications that require real-time data analysis. With its high-speed processing capabilities and built-in algorithms, it can quickly and efficiently process large volumes of data, enabling users to extract valuable insights and make informed decisions.

Moreover, the module supports various data communication protocols, allowing for seamless integration with different systems and devices. This enables data exchange between the module and external devices, facilitating a streamlined workflow and enhancing overall system efficiency.

With its exceptional performance and reliable operation, the 1769-iq16 module is a valuable tool in a wide range of industrial automation and control applications. Its robust design, advanced features, and extensive compatibility make it a preferred choice among professionals seeking a versatile and reliable solution for their data acquisition and processing needs.

Exploring the Application Possibilities and Benefits

When it comes to the innovative 1769-iq16 device, the potential applications and advantages are numerous and diverse. This section aims to highlight the wide range of possibilities that this cutting-edge technology brings to various industries and explore the significant benefits it offers.

Enhancing Automation Processes

With its advanced features and functionalities, the 1769-iq16 opens up a world of opportunities for automation processes. From industrial manufacturing to building management systems, this device enables seamless integration and control of various sensors and actuators, optimizing efficiency and productivity.

Improving System Monitoring and Maintenance

One of the major advantages of the 1769-iq16 is its ability to provide accurate and real-time data on the status of connected devices. This invaluable information allows for proactive monitoring and preventive maintenance, minimizing downtime and reducing overall costs. Furthermore, the device’s reliability and durability ensure long-term performance without compromising accuracy.

From a broader perspective, the 1769-iq16 can be utilized in several industries, including but not limited to manufacturing, energy, transportation, and healthcare. Its versatility and adaptability make it an ideal choice for applications ranging from monitoring critical equipment to optimizing energy consumption.

Overall, the 1769-iq16 offers immense potential for businesses and organizations seeking to enhance their automation processes, improve system monitoring capabilities, and boost overall efficiency and productivity. By exploring the various application possibilities and taking advantage of its numerous benefits, industries can unlock new opportunities and stay at the forefront of technological advancements.

Key Considerations for Effective Utilization in Industrial Automation

When it comes to industrial automation, there are several key considerations that must be taken into account to ensure effective utilization. In this section, we will explore these important factors and highlight their significance in optimizing industrial automation systems.

Understanding Operational Requirements

One crucial aspect of industrial automation is a comprehensive understanding of the operational requirements. Identifying the specific needs and expectations of the industrial processes being automated is essential for successful implementation. This includes considering factors such as production goals, system throughput, reliability, safety, and regulatory compliance. By having a clear understanding of these requirements, organizations can make informed decisions on the appropriate automation solutions to employ.

Ensuring Compatibility and Scalability

Another key consideration is ensuring compatibility and scalability of the automation systems. Industrial processes are often dynamic and evolving, requiring adaptable automation solutions. It is important to choose automation components that can integrate seamlessly with existing infrastructure and technologies. Additionally, scalability is crucial to accommodate future growth and expansions. Considering the ability of the automation system to scale and adapt to changing needs helps ensure long-term success and cost-effectiveness.

Furthermore, effective utilization in industrial automation necessitates the utilization of robust and reliable components that can withstand the demanding environments commonly encountered in industrial settings. This includes selecting high-quality sensors, controllers, and communication devices that can tolerate harsh operating conditions, such as extreme temperatures, humidity, vibrations, and electromagnetic interference.

Additionally, proper training and education of personnel involved in the operation and maintenance of the automation systems cannot be overlooked. Providing comprehensive training programs and resources for the workforce ensures that they possess the necessary skills and knowledge to effectively utilize the automation systems and troubleshoot any issues that may arise.

In summary, key considerations for effective utilization in industrial automation revolve around understanding operational requirements, ensuring compatibility and scalability, utilizing robust components, and providing adequate training. By addressing these factors, organizations can optimize their industrial automation systems, improve productivity, and achieve greater efficiency and competitiveness.