In the world of metallurgy, there are certain steel alloys that exhibit exceptional strength, durability, and versatility. One such alloy, often referred to as 4140, has gained immense popularity in various industrial applications. Recognized for its exceptional mechanical properties and excellent machinability, this steel specification has become a cornerstone in the manufacturing industry.

Unveiling the Alloys’ Strength:

To comprehend the true significance of 4140, it is essential to delve into the alloy’s composition and properties. This steel specification primarily consists of iron and carbon, mixed with a variety of other elements such as chromium, molybdenum, and manganese. These additional components impart specific characteristics to the alloy, including increased hardness, superior wear resistance, and a remarkable ability to withstand high temperatures.

Exploring the Potential Applications:

The unique combination of excellent mechanical properties and extraordinary machinability makes 4140 an ideal choice for a plethora of applications. From automotive parts and heavy machinery components to aerospace structures and oil field equipment, this steel specification has proven its mettle in diverse industries. Engineers and manufacturers rely on the 4140 datasheet to understand the alloy’s capabilities and design products that can withstand extreme conditions and demanding environments.

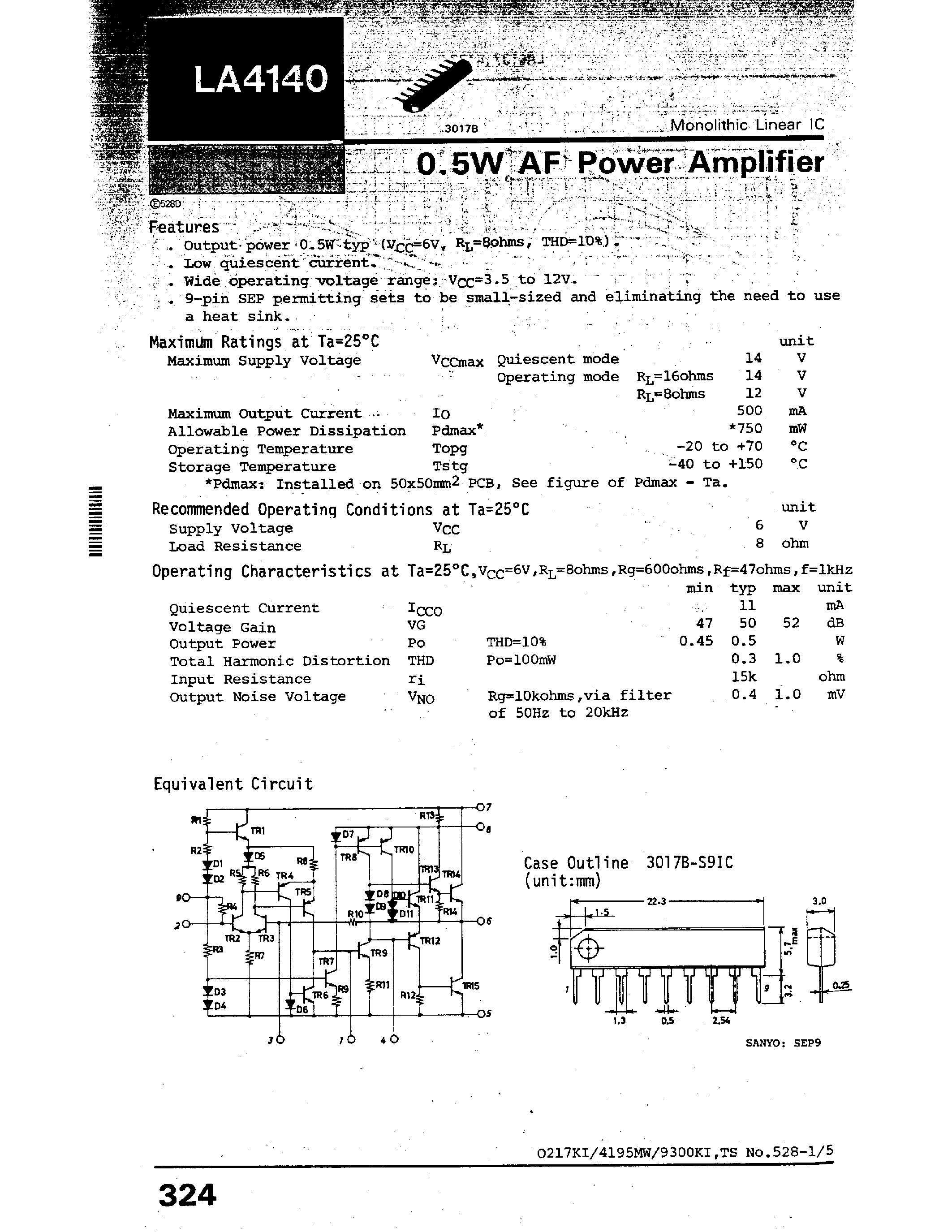

An Overview of 4140 Datasheet:

While the term “datasheet” may be misleading, as it typically refers to a technical document containing specific information, the 4140 datasheet serves as a crucial resource for material engineers, designers, and manufacturers. This informational document provides comprehensive details about the properties, composition, heat treatment, and other crucial specifications of this alloy. By referring to the 4140 datasheet, professionals gain valuable insights into the alloy’s suitability for their intended applications, allowing them to make informed decisions during the design and manufacturing process.

Overview of 4140 Datasheet

In this section, we will provide a comprehensive overview of the information contained within the 4140 datasheet. This document serves as a valuable resource for understanding the specifications, characteristics, and applications of the 4140 material.

Introduction

The introduction of the datasheet will give an overview of the significance and relevance of the 4140 material in various industries. It will highlight the diverse range of applications where the 4140 alloy steel is used, showcasing its versatility and performance.

Technical Specifications

This section will delve into the technical specifications of the 4140 material, presenting key parameters such as chemical composition, mechanical properties, and heat treatment recommendations. It will provide a detailed breakdown of the alloy’s composition, emphasizing its strength, toughness, and wear resistance.

Furthermore, the section will discuss the various testing methods employed to evaluate the quality and performance of the 4140 material. It will cover the testing standards, such as tensile strength, hardness, and impact testing, providing insights into the material’s structural integrity and reliability.

Additionally, the datasheet will outline the recommended heat treatment processes for the 4140 alloy steel, including tempering, quenching, and annealing. It will elucidate the impact of these processes on the material’s properties, enabling users to optimize the 4140 alloy for their specific applications.

Applications

The applications section will highlight the wide array of industries where the 4140 alloy steel finds utility. It will showcase its usage in sectors such as automotive, aerospace, oil and gas, construction, and machinery. Specific examples and case studies will be provided to exemplify the material’s effectiveness in various functional components and structures.

Moreover, this section will also emphasize the potential advantages and benefits of implementing the 4140 alloy steel over alternative materials, showcasing its cost-effectiveness, durability, and suitability for demanding environments.

In conclusion, the overview of the 4140 datasheet aims to provide readers with a comprehensive understanding of the material’s characteristics, specifications, and applications. It serves as a valuable reference for engineers, researchers, and manufacturers seeking to harness the unique properties of the 4140 alloy steel in their projects.

Key Properties and Characteristics of 4140 Steel

Steel alloy 4140 possesses a range of unique properties and characteristics that make it a highly sought-after material in various industries. This article aims to provide an overview of the key features and qualities of this versatile steel, without relying on specific terminology or definitions.

Tensile Strength and Durability

One of the notable characteristics of 4140 steel is its impressive tensile strength, which refers to its ability to withstand pulling or stretching forces without deformation or breaking. This steel alloy exhibits excellent durability, making it suitable for applications where high-stress conditions are present.

Hardness and Resistance to Wear

4140 steel features a high level of hardness, indicating its resistance to indentation, scratches, and wear. This property makes it highly suitable for components and parts that are exposed to abrasive conditions or require a long lifespan, such as gears, shafts, and tooling.

Additionally, the steel’s resistance to wear allows it to maintain its shape and integrity even under demanding operating conditions, ensuring optimal performance and reliability.

Chemical Composition

4140 steel contains a combination of various alloying elements, including chromium, manganese, and molybdenum, which contribute to its unique properties. These alloying elements enhance the steel’s strength, hardness, and overall performance, making it a popular choice in industries such as automotive, aerospace, and manufacturing.

Heat Treatment and Versatility

Another distinguishing characteristic of 4140 steel is its versatility in terms of heat treatment. This steel alloy can be subjected to various heat treatment processes, such as quenching and tempering, to achieve different levels of hardness, strength, and toughness.

Additionally, the versatility of 4140 steel allows it to be machined, welded, and formed into different shapes and sizes, making it a preferred material for complex and customized components.

In conclusion, 4140 steel offers a combination of strength, hardness, durability, and versatility, making it a valuable material in numerous applications. Its exceptional properties make it an attractive choice for industries requiring reliable and high-performance components.

Applications and Uses of 4140 Steel

Known for its exceptional strength, durability, and versatility, 4140 steel is widely used across various industries and applications. This high-quality alloy steel offers a wide range of benefits, making it a popular choice in the manufacturing world.

Automotive Industry:

As a strong and tough steel, 4140 is extensively used in the automotive industry for various components and parts that require high strength and reliability. It is commonly found in crankshafts, axle shafts, gears, and suspension components.

Aerospace Industry:

The aerospace industry also heavily relies on 4140 steel due to its exceptional mechanical properties and fatigue resistance. It is used in the construction of aircraft landing gears, engine components, and structural parts. Its ability to withstand high temperatures and corrosive environments makes it suitable for aerospace applications.

Oil and Gas Industry:

In the oil and gas industry, 4140 steel finds its use in various drilling and extraction equipment. Its high tensile strength and toughness make it suitable for critical components such as drill stems, dowels, and offshore drilling rig components.

Machinery and Tooling:

4140 steel is widely used in the manufacturing of machinery and tooling due to its excellent hardenability, wear resistance, and machinability. It is often utilized in the production of molds, dies, shafts, and gears.

Construction:

Due to its strength and versatility, 4140 steel is also used in the construction industry. It can be found in the fabrication of structural components, such as beams, columns, and connecting rods, as well as in the manufacturing of heavy machinery used in construction sites.

Sporting Equipment:

Another surprising application of 4140 steel is in the production of sporting equipment. Its high strength, impact resistance, and hardness make it suitable for manufacturing golf club heads, bicycle frames, and other sports equipment that require durability and performance.

Overall, the applications and uses of 4140 steel are vast and diverse. Its unique combination of properties makes it an ideal choice for industries requiring strength, durability, and reliability in their products and components.