In the world of advanced polymer coatings, a remarkable material has emerged – Parylene HT. Delivering exceptional performance in extreme heat environments, this cutting-edge coating solution has revolutionized numerous industries. With its unique composition and unparalleled thermal stability, Parylene HT proves to be a game-changer for applications requiring uncompromising protection and reliability at elevated temperatures.

What sets Parylene HT apart is its ability to withstand and thrive in extreme heat conditions that would typically degrade or damage standard coatings. This extraordinary polymer boasts an impressive upper-limit temperature rating, enabling it to perform flawlessly in environments where other coatings fail to endure. In essence, Parylene HT opens up a realm of possibilities for industries demanding reliable and long-lasting protection for their critical components in the harshest of thermal environments.

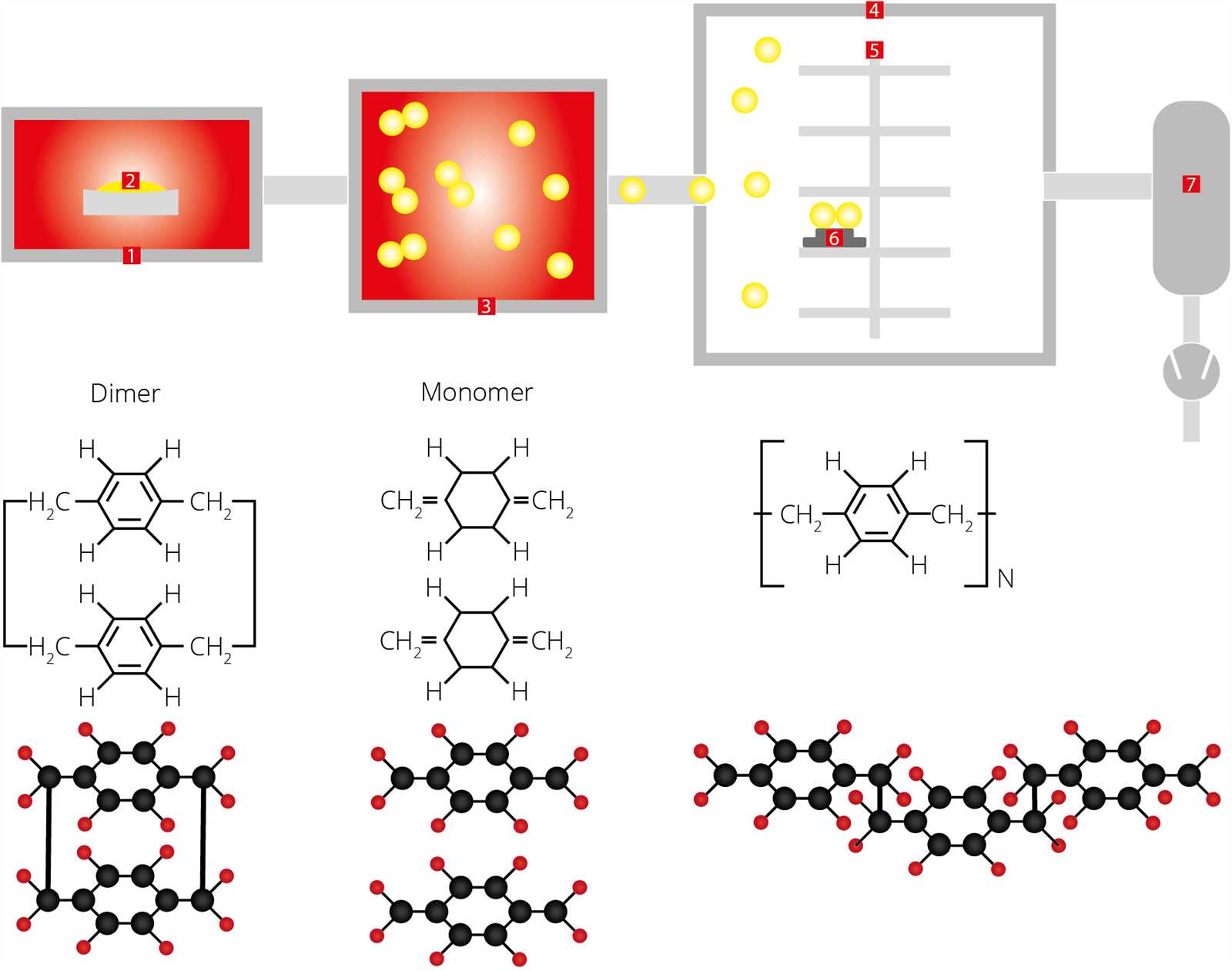

The exceptional thermal stability of Parylene HT can be attributed to its unique chemical structure and inherent properties. Engineered with a composition designed to withstand extreme heat, this high-temperature coating forms a dense, pinhole-free, and conformal film upon application. This film acts as an impenetrable shield, protecting delicate substrates from the detrimental effects of prolonged exposure to high temperatures – a trait that is particularly beneficial in demanding applications such as aerospace, automotive, and electronic industries.

Furthermore, the versatility of Parylene HT extends beyond its exceptional thermal resistance. This advanced coating exhibits outstanding mechanical properties, including high abrasion resistance and excellent dielectric properties, making it an ideal choice for applications where durability and electrical insulation are critical. Its superb adhesion to a wide range of substrates, coupled with its remarkable moisture and chemical resistance, elevate Parylene HT’s value even further, ensuring unmatched performance over extended periods of time.

As we delve deeper into the world of Parylene HT, this article aims to provide an in-depth exploration of its unparalleled capabilities, highlighting its key attributes, real-world applications, and potential benefits. By shedding light on this revolutionary high-temperature coating, we aim to showcase the vast potential it holds in solving complex challenges across diverse industries, ultimately paving the way for a new era of innovation and reliability.

Parylene HT Datasheet: A Comprehensive Overview

When it comes to a detailed understanding of the properties and applications of Parylene HT, there is no better resource than its comprehensive datasheet. This article provides a comprehensive overview of the Parylene HT datasheet, offering valuable insights into its unique characteristics and potential uses.

Understanding the Key Features of Parylene HT

One of the most distinguishing features of Parylene HT is its exceptional thermal stability. With a high glass transition temperature and excellent resistance to extreme temperatures, this advanced polymer coating is capable of withstanding harsh thermal environments. Furthermore, its exceptional chemical resistance makes it an ideal choice for a wide range of applications in various industries.

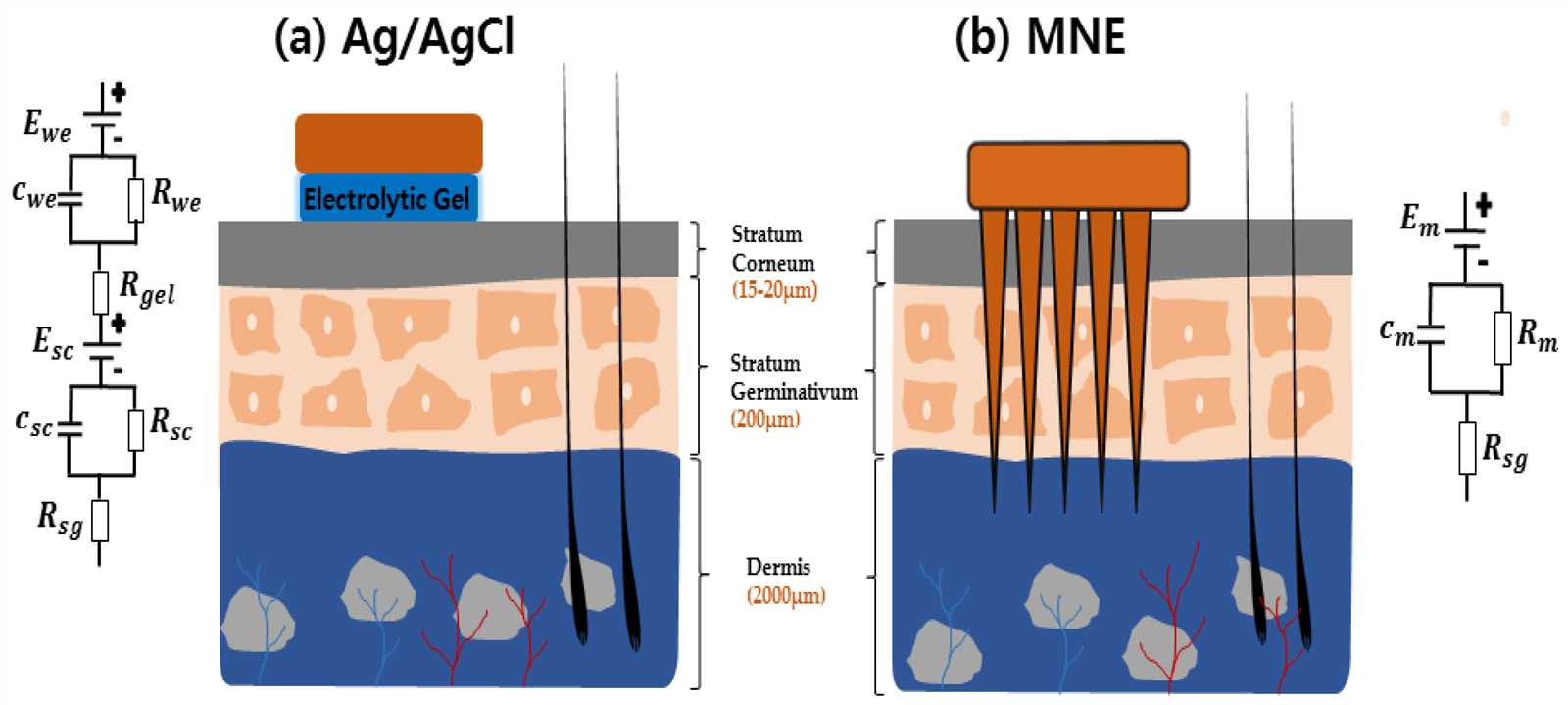

Moreover, Parylene HT offers outstanding electrical insulation properties, making it an excellent option for electronic components that require protection against moisture, chemicals, and other environmental factors. Its low dielectric constant and high dielectric breakdown voltage ensure reliable performance even in demanding electrical applications.

Exploring the Applications of Parylene HT

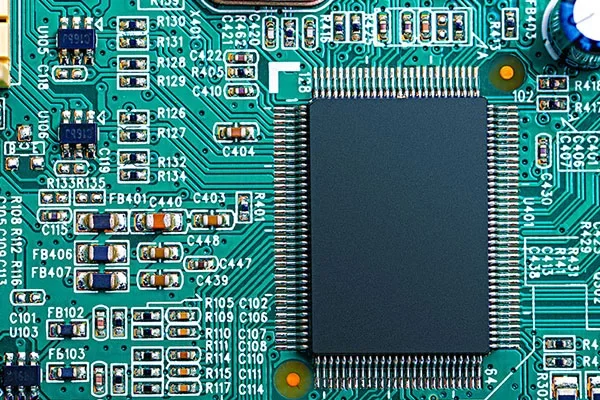

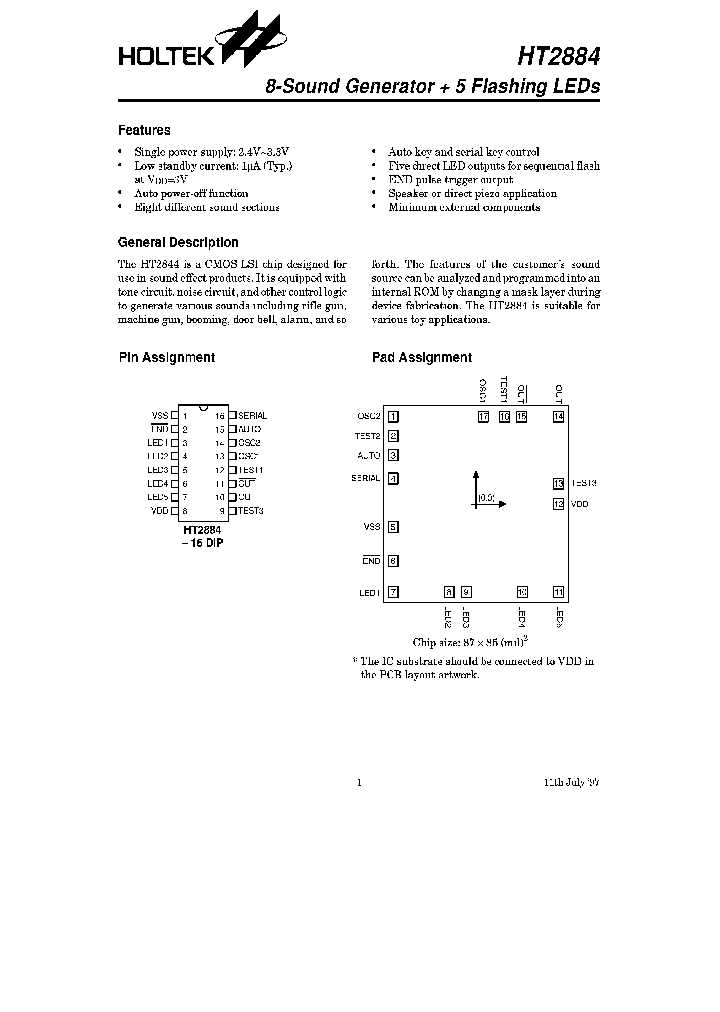

Due to its exceptional thermal and chemical stability, Parylene HT finds extensive use in various industries. Its ability to withstand extreme temperatures and maintain its structural integrity makes it a preferred choice for high-temperature electronics and sensor applications. Additionally, Parylene HT’s excellent electrical insulation properties make it highly suitable for coating printed circuit boards, sensors, and other electronic components.

Furthermore, Parylene HT’s chemical resistance makes it an ideal choice for applications where protection against corrosive substances, moisture, and other chemicals is critical. Industries such as automotive, aerospace, medical devices, and oil and gas greatly benefit from the protective properties offered by Parylene HT.

In conclusion, the Parylene HT datasheet provides a comprehensive overview of this advanced coating’s unique features and potential applications. Its thermal stability, chemical resistance, and excellent electrical insulation properties make it an ideal choice for a wide range of industries. By referring to the datasheet, engineers and designers can gain valuable insights into the capabilities of Parylene HT, enabling them to make informed decisions for their specific applications.

Understanding Parylene HT: Properties and Applications

In this section, we will delve into the various properties and applications of a unique material known as Parylene HT, exploring its versatility and potential benefits in different industries. By gaining an understanding of Parylene HT, we can appreciate its wide-ranging uses and the advantages it offers in terms of durability, protection, and performance.

| Superior Thermal Stability |

Parylene HT boasts exceptional thermal stability, allowing it to withstand extreme temperatures without compromising its structural integrity. This makes it an ideal choice for applications where heat resistance is crucial, ensuring reliable performance even in the most demanding conditions. |

| Excellent Chemical Resistance |

The inherent chemical resistance of Parylene HT makes it highly suitable for environments that are prone to exposure to corrosive substances or harsh chemicals. Its ability to resist degradation from acids, bases, solvents, and fuels makes it an invaluable material in industries such as aerospace, electronics, and medical devices. |

| Impressive Dielectric Properties |

With its exceptional dielectric properties, Parylene HT is an excellent electrical insulator. It possesses a high dielectric strength, low dissipation factor, and low moisture absorption, making it a dependable choice for electrical and electronic applications, including insulation, encapsulation, and protection of sensitive components. |

| Biocompatibility and Bioinertness |

Parylene HT is biocompatible and bioinert, meaning it does not interact with living tissue and has minimal to no biological response. This makes it a preferred material for medical devices and implants, where compatibility with the human body is of utmost importance. Its ability to resist biofouling adds to its value in various healthcare applications. |

| A Wide Range of Applications |

Parylene HT finds application in a myriad of industries, including aerospace, automotive, electronics, medical, and military. Its unique combination of properties enables it to enhance the performance, reliability, and longevity of products such as circuit boards, sensors, implants, MEMS devices, and more. |

With these exceptional properties and diverse applications, Parylene HT proves to be a material of choice in many industries, offering unparalleled protection, reliability, and performance for critical components and devices.

Parylene HT Datasheet: Technical Specifications and Performance Data

Exploring the intricacies of Parylene HT, this section delves into its technical specifications and performance data, providing a comprehensive overview of its properties and capabilities.

With a focus on practical application, this section presents a thorough analysis of the unique characteristics and performance of Parylene HT. It highlights its exceptional thermal stability, resistance to chemicals, and dielectric properties, making it an ideal choice for demanding high-temperature environments.

Delving deeper, we examine the material’s mechanical strength and adhesion properties, showcasing its ability to withstand harsh conditions and adhere to various substrates. Furthermore, the section explores its electrical insulation capabilities and moisture resistance, underscoring its suitability for a wide range of electronic and industrial applications.

The Parylene HT datasheet presents helpful information on the material’s thickness range, emphasizing its versatility and applicability in various industries. Additionally, it provides valuable insight into its operating temperature range and UV stability, ensuring optimal performance and longevity in challenging conditions.

By presenting clear and concise data, this section equips engineers and researchers with the necessary technical information to make informed decisions when considering Parylene HT for their specific applications. It offers a comprehensive overview of the material’s performance capabilities, highlighting its unique attributes that set it apart from other conformal coatings and protective films.

Ultimately, this section aims to provide a detailed understanding of Parylene HT’s technical specifications and performance data, empowering readers to harness its full potential and confidently incorporate it into their projects.

Recommendations for Handling and Processing Parylene HT

When working with the high-temperature variant of Parylene, it is crucial to follow proper handling and processing guidelines to ensure optimal performance and product integrity. This section provides important recommendations and best practices for working with Parylene HT, taking into consideration the specific characteristics and properties of this advanced material.

First and foremost, it is essential to adhere to all recommended safety precautions when handling Parylene HT. This includes working in a well-ventilated area and wearing appropriate protective equipment to prevent any potential hazards. Additionally, ensure that the work area is clean and free from any contaminants that may compromise the integrity of the material.

When processing Parylene HT, it is important to carefully consider the temperature limitations and requirements. Parylene HT is designed to withstand high operating temperatures, making it suitable for applications that involve extreme heat. However, it is crucial to avoid exceeding the specified temperature range during the processing phase to prevent any adverse effects on the material’s properties.

Proper surface preparation is also key when working with Parylene HT. Thoroughly clean and degrease the substrate before applying the coating to ensure optimal adhesion and durability. This may involve using appropriate cleaning agents and techniques specific to the substrate material and the intended application.

Furthermore, it is recommended to conduct thorough testing and evaluation of Parylene HT-coated components or products before integration or deployment. This can help identify any potential issues or areas for improvement in the processing or handling methods, ensuring the highest level of quality and reliability.

In conclusion, by following the recommendations outlined in this section, you can ensure safe and effective handling and processing of Parylene HT, maximizing the performance and longevity of your products or components. With proper attention to detail and adherence to best practices, you can harness the full potential of this high-temperature variant of Parylene in your applications.