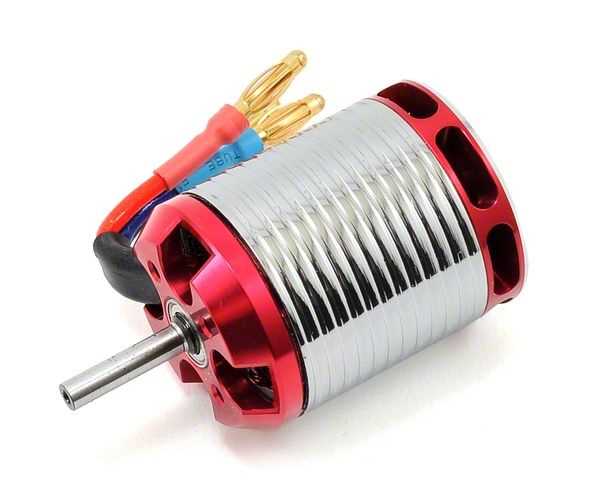

In the realm of modern propulsion systems, there exists a vital component whose characteristics dictate the performance of diverse electronic mechanisms. This elemental entity, often regarded as the quintessence of dynamic motion, harbors an array of attributes that govern its functionality in numerous applications. Within the intricate world of technological innovation, understanding the intricacies of this core unit becomes paramount.

Unraveling the Enigmatic Traits

Delving into the depths of its technical documentation unveils a plethora of intricately detailed features, encapsulating its potential and operational intricacies. This compendium of specifications serves as a roadmap, guiding enthusiasts and engineers through the labyrinth of possibilities inherent within this electronic powerhouse.

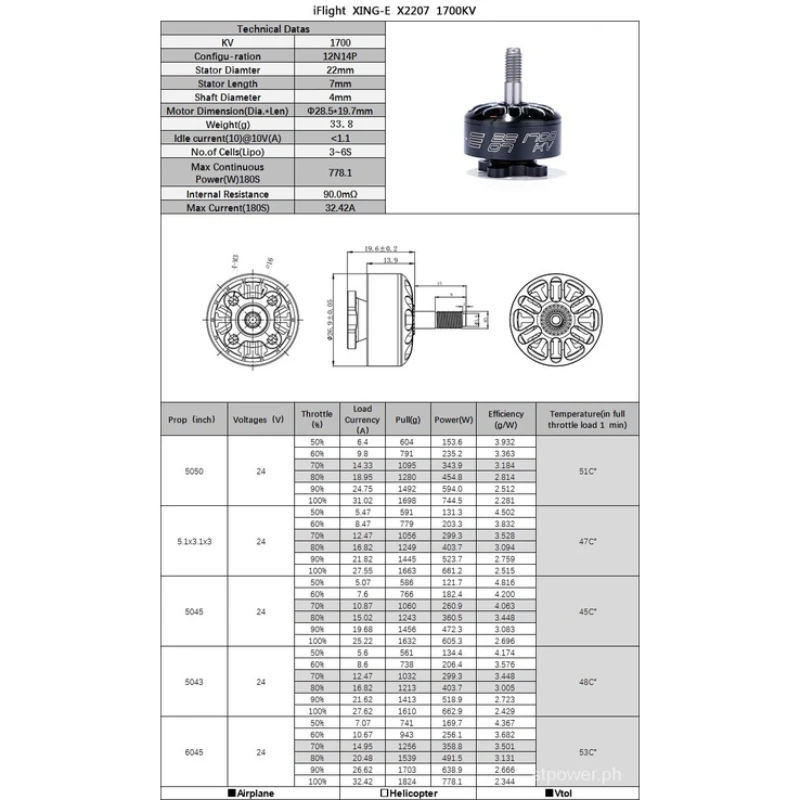

Embarking on a journey of discovery, one scrutinizes the numerical values, graphs, and diagrams that paint a vivid portrait of its capabilities.

The Essence of Performance

Examining the performance metrics without prejudice, one discerns the subtleties that differentiate mere adequacy from exceptional proficiency. Through rigorous analysis and empirical observation, the essence of its prowess emerges, shedding light on its ability to propel machinery to unparalleled heights.

Thus, within the confines of its datasheet lie the blueprints of innovation, awaiting the adept hands of those poised to harness its full potential.

Understanding the Significance of Technical Specifications for Brushless Motors

Delving into the intricate world of electric propulsion systems unveils a realm where meticulous attention to technical details reigns supreme. Amidst the labyrinth of specifications and figures lies a crucial cornerstone: the comprehensive documentation that delineates the essence of a motor’s prowess. Within these datasheets lie the roadmap to unlocking the full potential of propulsion systems, guiding enthusiasts and engineers alike towards optimal performance and efficiency.

The Basics: Deciphering 1800kv Brushless Motor Specifications

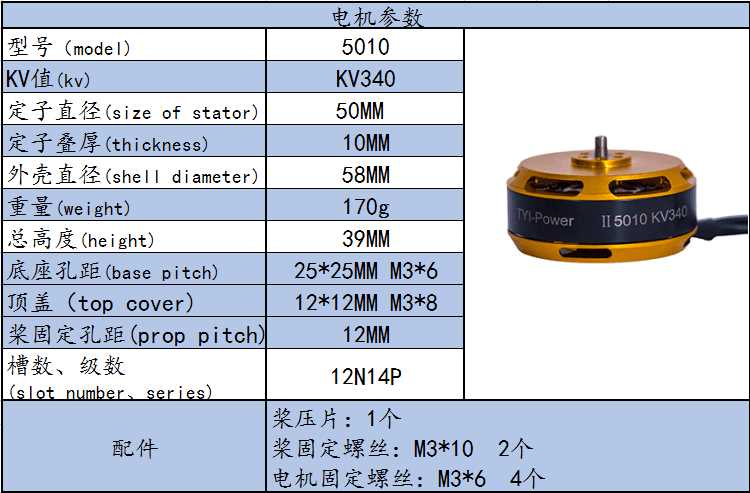

Understanding the intricacies of specifications for these high-powered propulsion components entails delving into a realm of technical nuances. In this section, we embark on a journey to unravel the fundamental elements that compose the blueprint guiding the performance of these dynamic electromechanical devices.

Core Attributes:

At the heart of comprehending the capabilities of these propulsion systems lies a grasp of their core attributes. These encompass factors influencing power output, efficiency, and operational parameters.

Performance Metrics:

Within the realm of deciphering specifications, discerning the various performance metrics provides insight into the motor’s prowess. These metrics encapsulate indicators of speed, torque, and operational limits, delineating the boundaries within which the motor operates.

Structural Characteristics:

Beyond performance metrics, understanding the structural characteristics elucidates the motor’s physical composition and design. Factors such as size, weight, and construction materials play pivotal roles in determining suitability for diverse applications.

Operational Considerations:

Moreover, operational considerations delve into the intricacies of voltage requirements, compatibility with electronic speed controllers (ESCs), and thermal management strategies. Mastery of these facets ensures optimal integration and performance within a myriad of propulsion systems.

Conclusion:

In summation, navigating the labyrinthine realm of deciphering specifications for these propulsion powerhouses necessitates a holistic understanding of their core attributes, performance metrics, structural characteristics, and operational considerations. Mastery of these facets empowers enthusiasts and engineers alike to harness the full potential of these dynamic electromechanical marvels.

Performance Analysis: Deciphering Information for Optimal Motor Selection

When delving into the intricacies of selecting the ideal propulsion system for your project, a nuanced understanding of performance metrics is paramount. This section aims to dissect the available data to empower informed decision-making, steering clear of jargon-laden specifications.

Understanding Efficiency: The efficiency of a propulsion unit delineates its ability to convert input power into useful output. This crucial metric illuminates the motor’s proficiency in translating electrical energy into mechanical motion, ultimately influencing overall system performance.

Exploring Power Output: Power output encapsulates the motor’s capacity to generate rotational force, measured in watts. A comprehensive grasp of this facet aids in gauging the motor’s suitability for specific applications, guiding users towards optimal performance thresholds.

Assessing Torque Characteristics: Torque, the rotational force exerted by the motor, underpins its ability to overcome resistance and initiate motion. Interpreting torque curves elucidates the motor’s torque delivery across varying speeds, furnishing invaluable insights into its operational dynamics.

Examining Thermal Management: Thermal considerations are indispensable in evaluating a motor’s longevity and reliability. By scrutinizing temperature thresholds and thermal dissipation capabilities, practitioners can preemptively address overheating concerns, safeguarding against premature wear and potential system failures.

Deriving Performance Indices: Synthesizing diverse performance metrics culminates in the derivation of comprehensive indices, facilitating direct comparisons between disparate motor models. This holistic approach empowers stakeholders to make judicious selections tailored to their unique project requirements.

Conclusion: Navigating the labyrinth of motor specifications necessitates a discerning eye and a nuanced understanding of performance data. By dissecting efficiency, power output, torque characteristics, thermal management, and overarching performance indices, individuals can navigate the intricate landscape of motor selection with confidence and precision.

Beyond Numbers: Practical Insights for Maximizing Motor Efficiency

In this section, we delve into the realm of enhancing the operational prowess of propulsion systems beyond mere numerical specifications. Unraveling the intricacies of optimizing the functionality of electric propulsion systems requires a comprehensive understanding that transcends conventional data points. We embark on a journey to uncover practical strategies and insights aimed at elevating the efficiency and performance of electric propulsion mechanisms.

| 1. Precision in Propulsion: | Efficiency in propulsion systems hinges not solely on raw power metrics, but on the meticulous calibration and synchronization of components. Fine-tuning the interplay between voltage, current, and rotational dynamics is paramount in unlocking the full potential of electric propulsion mechanisms. |

| 2. Harmonizing Components: | Achieving optimal efficiency necessitates a harmonious synergy between various system elements. From the intricacies of controller programming to the selection of compatible ancillary components, every facet must align seamlessly to minimize energy wastage and maximize output. |

| 3. Streamlining Mechanical Interfaces: | Efficient propulsion transcends the electrical domain; it encompasses the mechanical interfaces through which power is transmitted. Minimizing frictional losses, optimizing gear ratios, and implementing precision bearings are pivotal in mitigating energy dissipation and enhancing overall efficiency. |

| 4. Environmental Adaptability: | Efficient propulsion systems exhibit a capacity for adaptability to diverse environmental conditions. Whether navigating turbulent air currents or traversing challenging terrains, mechanisms optimized for efficiency demonstrate resilience and adaptability, thereby maximizing performance across varied operational scenarios. |

| 5. Iterative Optimization: | Enhancing motor efficiency is an iterative process that demands continual refinement and optimization. Through empirical testing, data-driven analysis, and innovative design iterations, propulsion systems evolve to achieve heightened levels of efficiency and performance. |

By transcending conventional numerical metrics and embracing a holistic approach to optimization, propulsion systems can realize their full potential, ushering in a new era of efficiency and performance in electric propulsion technology.