Imagine a world where information is seamlessly transmitted and power is efficiently controlled, allowing our modern technology-driven society to function smoothly. Behind the scenes of this interconnected web lies a multitude of electrical components, each with their own unique purpose and design. In this article, we delve into the enigmatic realm of a particular switching device known for its versatility and reliability.

Within the realm of electrical engineering, there exists a component that acts as a gatekeeper, directing electrical signals to their intended destinations. This crucial device, often referred to as a “double pole double throw relay,” possesses the ability to guide the flow of current, enabling the smooth operation of countless systems. Through the effective and efficient switching of electrical circuits, this device empowers everything from large-scale industrial automation to intricate electronic circuitry found in our everyday devices.

Unveiling the intricacies hidden within the pages of a technical document, this article aims to paint a vivid picture of the inner workings of this remarkable relay. By exploring its detailed specifications, mechanical features, and performance characteristics, we aim to shed light on the fundamental principles that drive its operation. Prepare yourself for a captivating journey into the world of electrical switching devices as we unravel the essence of this indispensable component.

Understanding the DPDT Relay: A Comprehensive Datasheet Analysis

In this section, we will delve into a thorough analysis of the DPDT relay, providing a comprehensive understanding of its functionality and applications. By examining the detailed specifications and characteristics outlined in the datasheet, we can gain valuable insights into the inner workings of this versatile electrical component.

1. Operating Principles

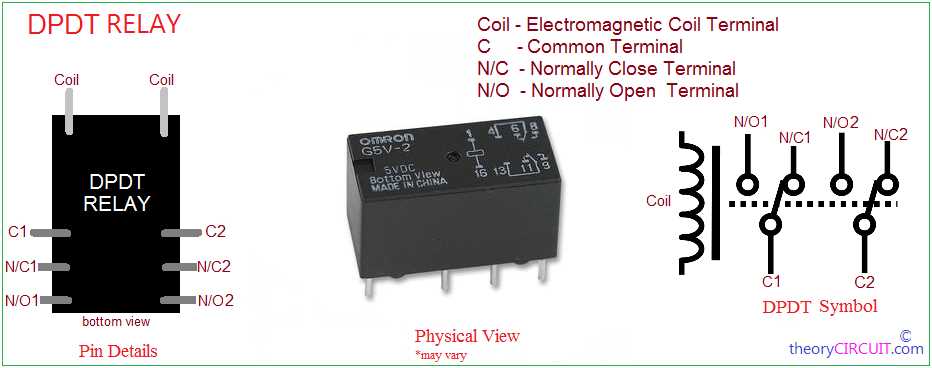

Firstly, it is vital to comprehend the underlying principles that govern the operation of a DPDT relay. By utilizing magnetic fields and electrical contacts, the relay facilitates the switching of circuits, allowing for the control of various electrical devices and systems. Understanding the operation principles is crucial in ensuring the proper utilization of the DPDT relay in specific applications.

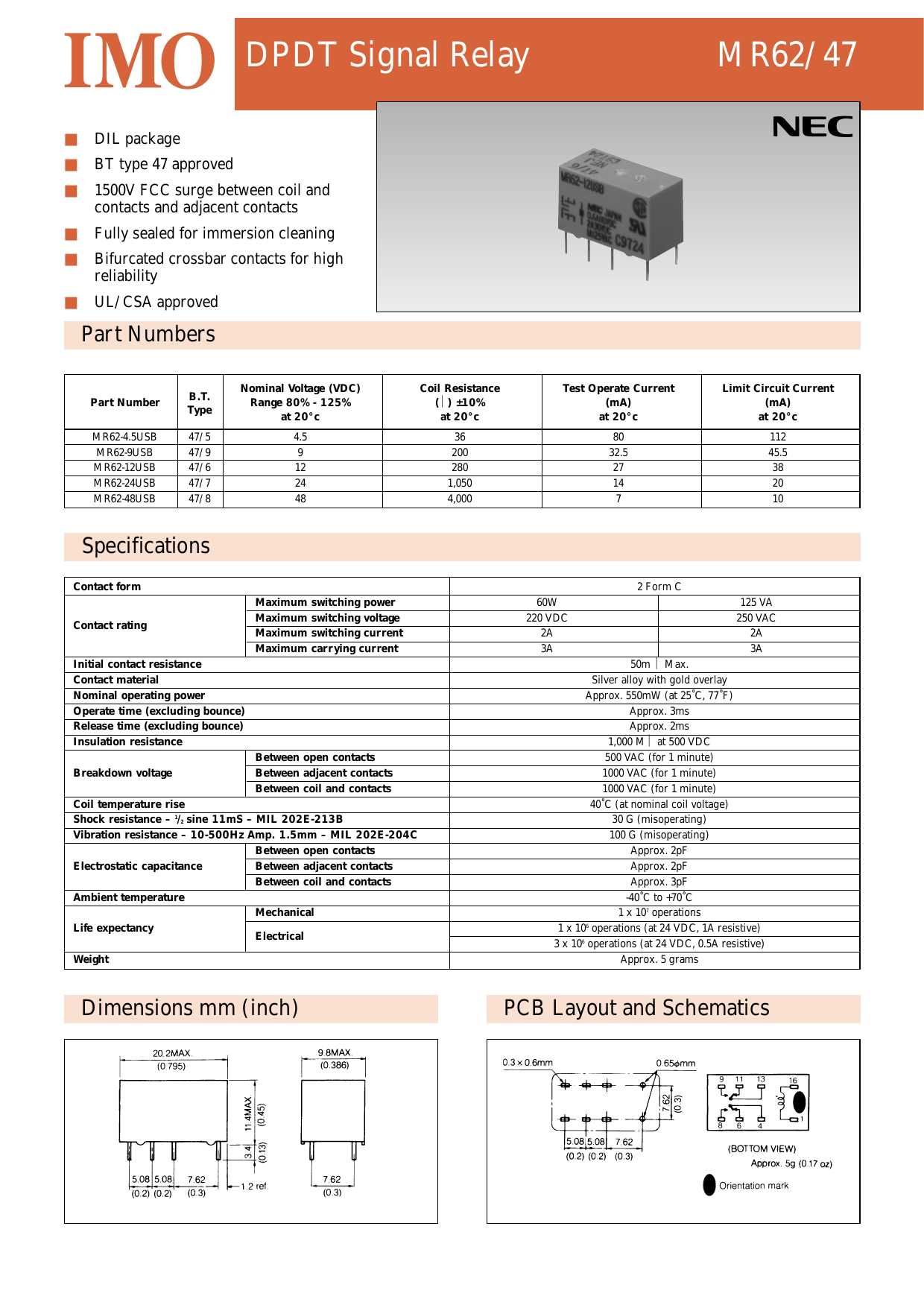

2. Key Specifications

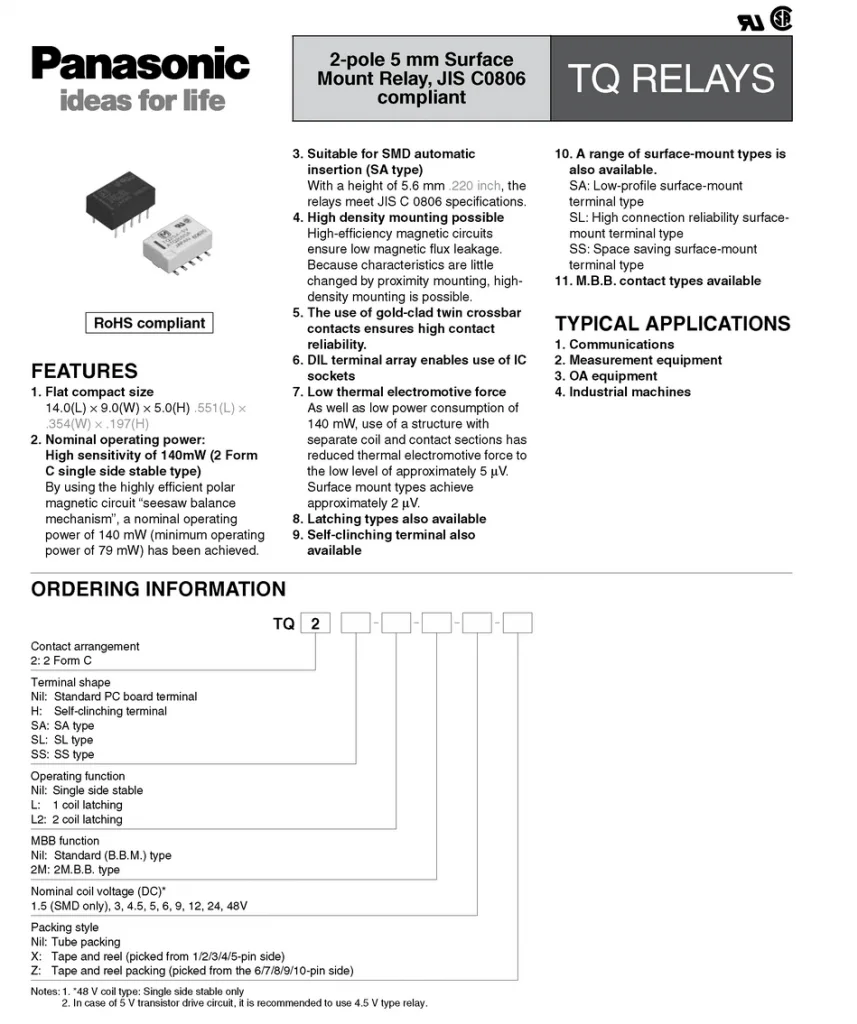

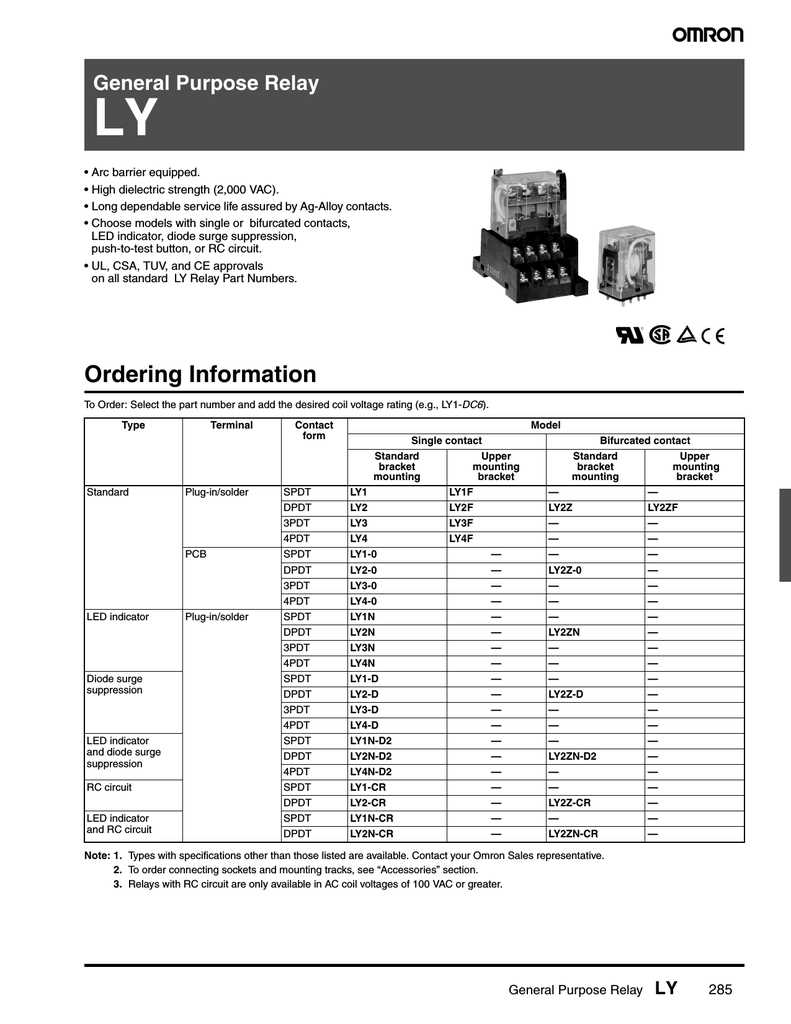

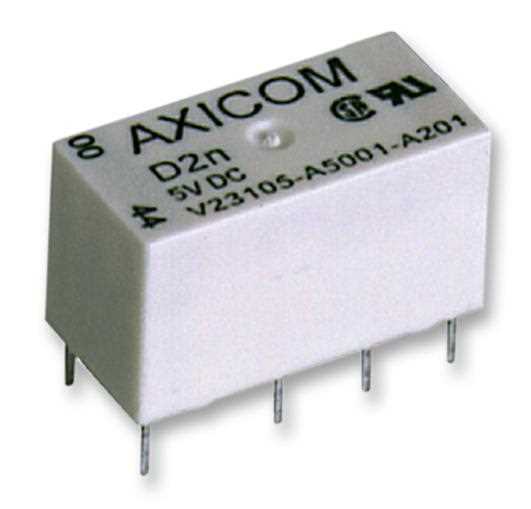

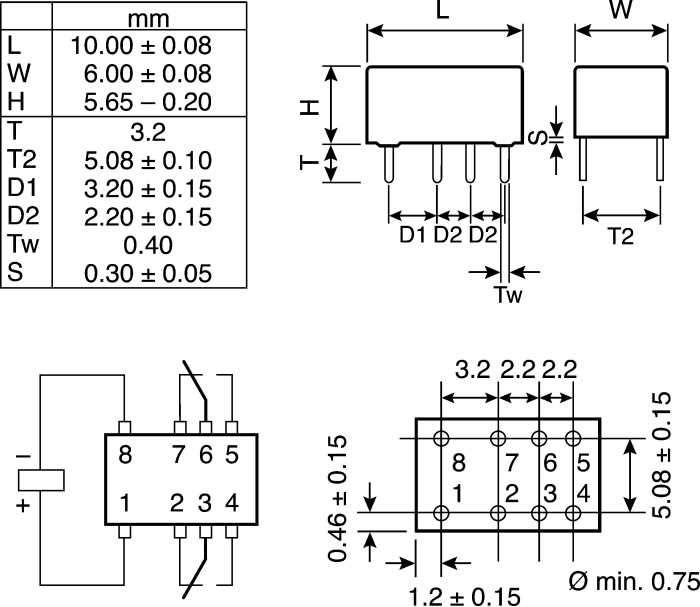

Next, we will explore the essential specifications outlined in the DPDT relay datasheet. These specifications include the contact ratings, coil characteristics, and mechanical features such as the dimensions and mounting options. By comprehending these specifications, users can make informed decisions regarding the suitability of the DPDT relay for their specific requirements.

- Contact Ratings: The datasheet provides information on the maximum current and voltage ratings for both the normally open (NO) and normally closed (NC) contacts. Understanding these ratings ensures that the relay can handle the required electrical loads without any risk of failure or damage.

- Coil Characteristics: By examining the coil characteristics, users can determine the required coil voltage and current, as well as the power consumption of the DPDT relay. This information is crucial for proper relay selection and ensuring compatibility with the electrical system.

- Mechanical Features: The datasheet also provides details on the physical dimensions, pin layouts, and mounting options of the DPDT relay. This information enables users to accurately position and integrate the relay into their electrical setups.

By thoroughly assessing the key specifications outlined in the DPDT relay datasheet, users can confidently incorporate this component into their projects, ensuring reliable and efficient operation.

Analyzing the Datasheet: Key Specifications and Performance Parameters

When examining the technical documentation associated with a particular component like a Dpdt relay, it is essential to delve into the details provided by the datasheet. This critical resource offers a wealth of information regarding the device’s specifications and performance parameters, allowing engineers and designers to make informed decisions about its suitability for a given application.

Understanding Key Specifications

Within the datasheet, certain specifications take center stage, providing vital insights into the capabilities and limitations of the Dpdt relay. These specifications encompass factors such as electrical ratings, mechanical dimensions, contact arrangements, and coil power consumption. By comprehending these numbers and figures, engineers can gauge how the relay will interact with their specific system requirements.

For instance, electrical ratings reveal crucial information about voltage and current limits, ensuring the relay can handle the anticipated load. Mechanical dimensions play a role in determining if the relay will fit within the designated space, optimizing installation and functionality. Contact arrangements indicate the specific internal connections within the relay, offering flexibility and compatibility options. Finally, coil power consumption provides insights into the relay’s energy requirements, aiding in designing efficient power management systems.

Evaluating Performance Parameters

In addition to key specifications, the datasheet also provides a range of performance parameters that allow engineers to assess the relay’s overall performance in various conditions and applications. These parameters include elements such as contact resistance, insulation resistance, and operating time.

Contact resistance measures the electrical resistance of the relay’s contacts when closed, enabling engineers to determine the efficiency and reliability of the electrical connection. Insulation resistance, on the other hand, determines the degree of isolation between different circuits or components within the relay, ensuring safe operation in high voltage systems.

Operating time refers to the time taken by the relay to transition between its stable positions, which is crucial in applications that require quick response times. By analyzing these performance parameters, engineers can select a Dpdt relay with the appropriate characteristics, ensuring optimal performance and compatibility within their specific system design.

| Specification | Definition |

|---|---|

| Electrical Ratings | The specified voltage and current limits the relay can handle. |

| Mechanical Dimensions | The physical size and shape of the relay. |

| Contact Arrangements | The specific internal connections within the relay. |

| Coil Power Consumption | The amount of power required to energize the relay’s coil. |

| Contact Resistance | The electrical resistance of the relay’s contacts when closed. |

| Insulation Resistance | The degree of isolation between different circuits or components within the relay. |

| Operating Time | The time taken by the relay to transition between stable positions. |

Practical Tips and Considerations for Working with DPDT Relays

When it comes to employing DPDT relays in your projects, there are a few practical tips and considerations that can help you optimize their performance and ensure a successful outcome. Understanding the intricacies of these relays is essential for their efficient utilization. This article offers valuable insights and guidelines to help you navigate through the process without relying solely on a datasheet.

Understanding the DPDT Relay Operation

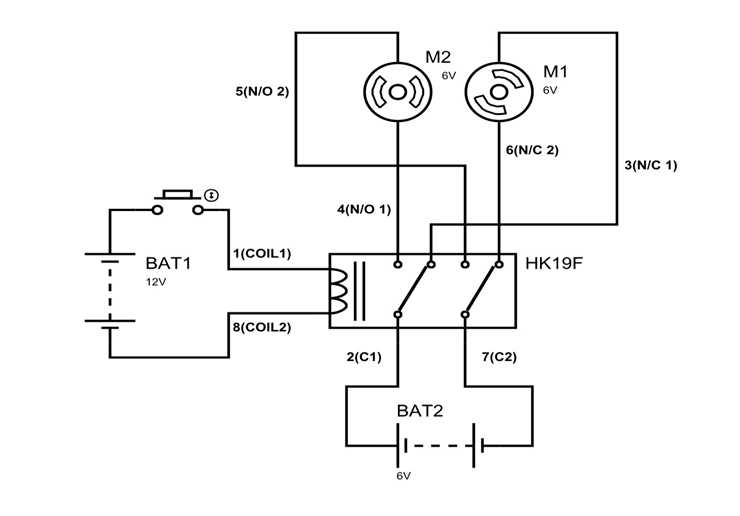

First and foremost, it is crucial to have a clear understanding of how DPDT relays operate. These double-pole, double-throw relays are commonly used to switch between two separate circuits. They are capable of controlling two separate devices simultaneously, making them a versatile choice in many applications.

When working with DPDT relays, it is important to pay close attention to the coil ratings and contact ratings. This includes understanding the coil voltage and current required for proper operation, as well as the maximum current and voltage the contacts can handle. These specifications can vary between different relays and are crucial for ensuring compatibility with your specific application.

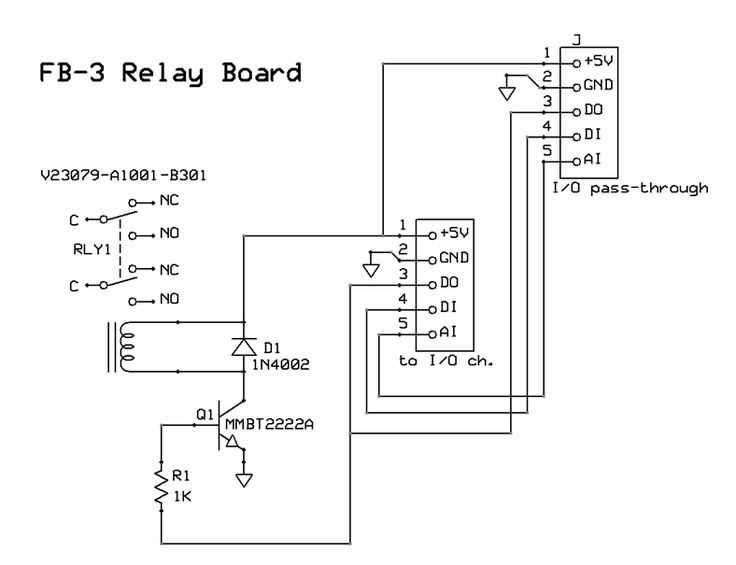

Considerations for Wiring and Connection

Proper wiring and connection of DPDT relays is essential for their optimal performance. When wiring a DPDT relay, it is important to adhere to the datasheet guidelines and follow the recommended wiring diagrams. Improper wiring can lead to circuit malfunctions or even failure of the relay, so attention to detail is key.

Additionally, it is advisable to consider the physical placement and proximity of the relay to other components in the circuit. Factors such as electromagnetic interference and heat dissipation can affect the reliability and longevity of the relay. Careful consideration of these factors during the design and installation phases can help mitigate any potential issues.

In conclusion, working with DPDT relays requires a solid understanding of their operation, proper wiring techniques, and consideration of various factors that can impact their performance. By following these practical tips and considerations, you can ensure a smooth and successful integration of DPDT relays into your projects, enhancing overall functionality and reliability.