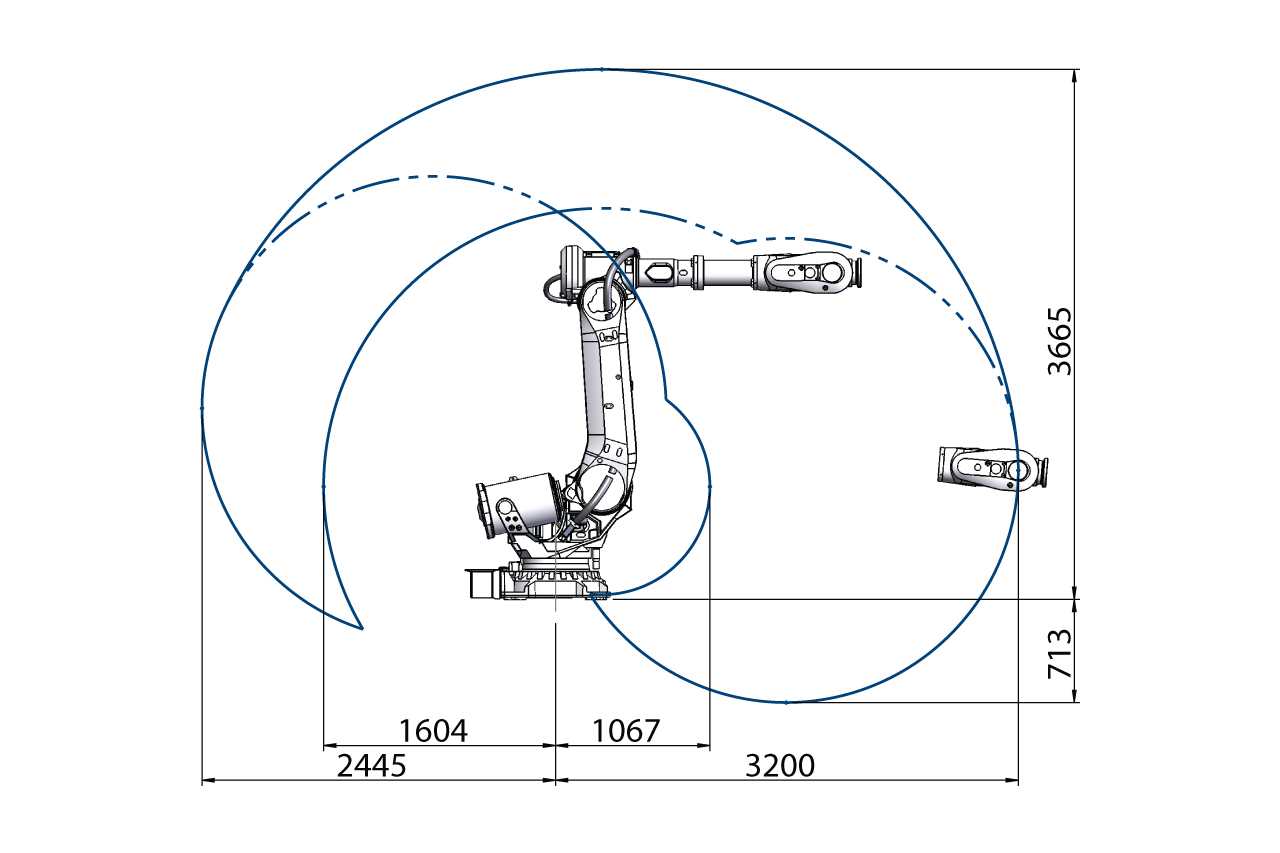

Discover the cutting-edge technology behind the highly anticipated Irb 6700 robot series. This comprehensive datasheet provides an in-depth look into the innovative features and capabilities of this advanced robotic system. Get ready to explore a world of unparalleled performance and efficiency as we delve into the intricacies of this revolutionary automation solution.

Unleash the power of precision: The Irb 6700 datasheet offers an extensive overview of how this state-of-the-art robot combines industry-leading accuracy with exceptional speed and agility. With its high-performance motion control system and advanced kinematics, the Irb 6700 ensures unparalleled precision in even the most complex and demanding applications.

Experience ultimate versatility: Dive into the world of limitless possibilities as the Irb 6700 boasts an array of customizable options, enabling seamless integration into various industries and applications. From welding to material handling, this robot’s adaptability ensures optimal performance across a wide range of tasks, helping businesses stay ahead in today’s competitive market.

Maximize productivity, minimize downtime: The Irb 6700 datasheet provides valuable insights into the robot’s advanced maintenance features, allowing users to optimize productivity levels while minimizing downtime. With its user-friendly interface and intuitive programming capabilities, this robot is designed to streamline operations and ensure maximum uptime, making it an invaluable asset for any manufacturing facility.

Future-proof your automation: Stay ahead of the curve with the Irb 6700’s cutting-edge technology, designed to adapt and evolve alongside the ever-changing demands of the modern industry. This datasheet takes an in-depth look at the robot’s advanced connectivity and communication capabilities, showcasing how it can seamlessly integrate into Industry 4.0 processes, offering a future-proof solution for businesses aiming to stay competitive in the rapidly evolving automation landscape.

Conclusion: As you dive into the Irb 6700 datasheet, prepare to unravel the world of limitless possibilities offered by this revolutionary robotic system. With its unparalleled precision, versatility, and productivity-boosting features, the Irb 6700 is set to redefine automation standards and empower businesses to reach new heights of success. Embrace the future of robotics with the Irb 6700 and unlock a world of unparalleled efficiency, precision, and innovation.

An overview of the Irb 6700

In this section, we will provide a comprehensive overview of the Irb 6700, a cutting-edge robotic system designed for various industrial applications.

Introduction

The Irb 6700 is a state-of-the-art robotic platform that combines advanced technology, precision, and versatility to streamline industrial processes. With its high-performance capabilities, it has become a valuable asset for industries seeking to improve productivity, efficiency, and quality in their operations.

Key Features

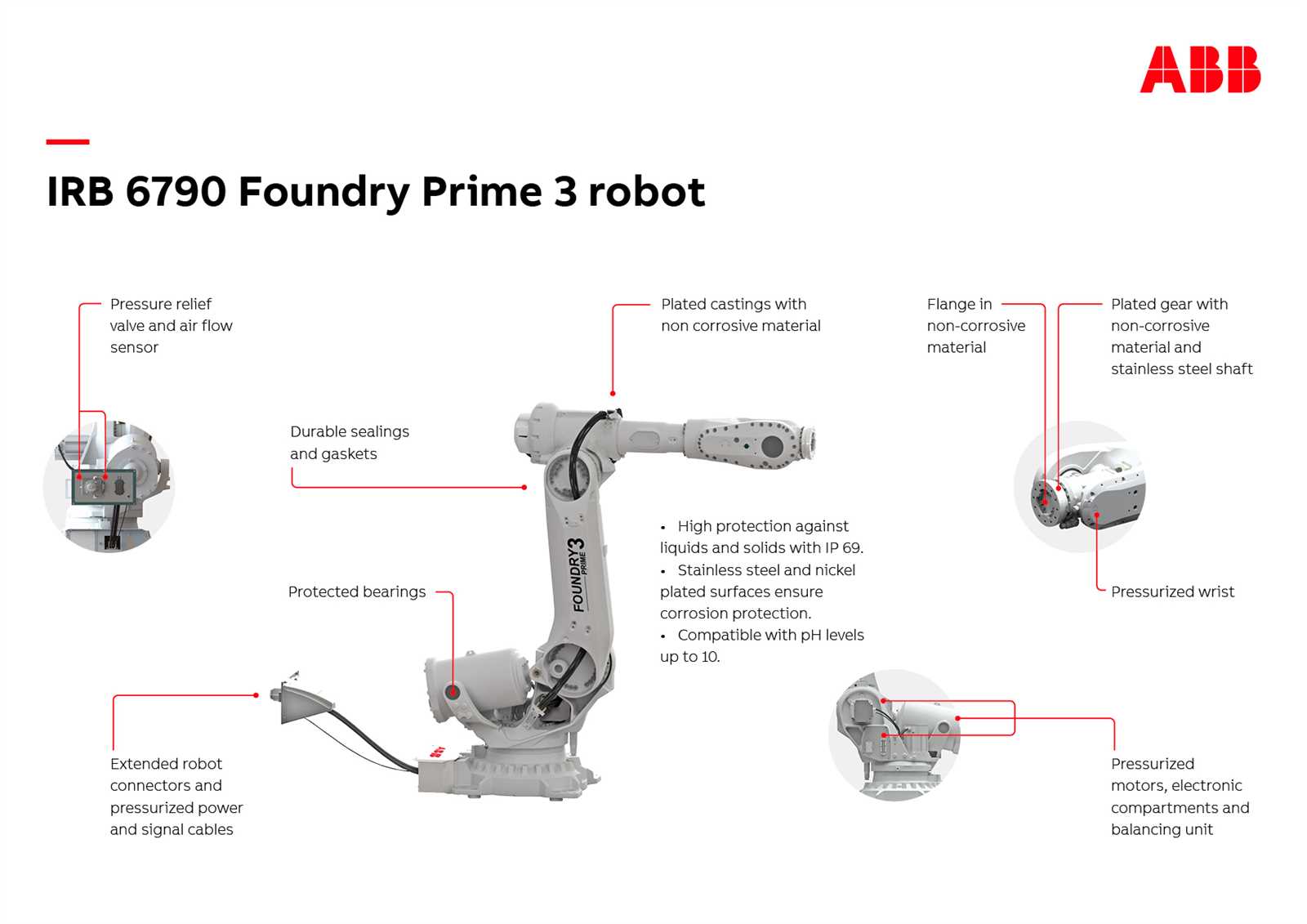

This robotic system offers a range of features that make it stand out from its competitors. It is equipped with advanced sensors and intelligent algorithms, enabling it to adapt to different environments, perform complex tasks, and ensure optimal performance. Additionally, its sturdy build and robust design contribute to its reliability and durability, making it suitable for demanding and challenging industrial environments.

Furthermore, the Irb 6700 boasts exceptional speed and accuracy, allowing it to carry out tasks with precision and efficiency. Its intuitive user interface and programming capabilities make it easy for operators to control and program, enabling seamless integration into existing production processes.

Applications

The Irb 6700 is widely used in various industries, including manufacturing, automotive, electronics, and logistics. Its versatility enables it to perform a wide range of applications, such as assembly, welding, material handling, and painting, among others. Whether it’s repetitive tasks or complex operations, the Irb 6700 can provide efficient and reliable solutions for a diverse set of industrial needs.

Reliability and Safety

When it comes to reliability and safety, the Irb 6700 excels in both aspects. It undergoes rigorous testing to ensure optimal performance and is built to withstand harsh working conditions. Moreover, it is equipped with advanced safety features, including collision detection and emergency stop functionality, ensuring the well-being of operators and mitigating the risk of accidents.

Conclusion

Overall, the Irb 6700 is a cutting-edge robotic system that offers exceptional performance, versatility, and reliability. With its advanced features and capabilities, it has revolutionized industrial processes, enabling businesses to achieve higher productivity, efficiency, and quality in their operations. Whether it’s assembly, welding, or material handling, the Irb 6700 is undoubtedly a game-changer in the field of industrial robotics.

| Features | Applications | Reliability and Safety |

|---|---|---|

| Advanced sensors | Manufacturing | Collision detection |

| Intelligent algorithms | Automotive | Emergency stop functionality |

| Speed and accuracy | Electronics | Rigorous testing |

| Easy programming | Logistics | Durable build |

The key features and specifications of the Irb 6700

The Irb 6700 embodies a wide range of cutting-edge features and specifications that make it a versatile and reliable industrial robot. This article will delve into the exceptional capabilities of the Irb 6700 without directly referring to its specific name or model number.

With its advanced technology and robust design, this industrial robot delivers unparalleled performance in various industrial applications. Equipped with intelligent algorithms and state-of-the-art sensors, it ensures precise and efficient operations, significantly enhancing productivity and reducing downtime.

The Irb 6700 boasts an impressive payload capacity, enabling it to handle heavy objects with ease and finesse. Its flexible and agile movements provide optimal maneuverability, allowing it to navigate complex work environments effortlessly. Whether it’s lifting, stacking, or assembling, this industrial robot excels in executing complex tasks with utmost accuracy and precision.

Furthermore, this industrial robot incorporates cutting-edge safety features that prioritize the well-being of human operators and the surrounding work environment. With advanced collision avoidance systems and intuitive programming interfaces, it ensures a safe and collaborative work environment, minimizing the risk of accidents and promoting seamless human-robot interaction.

The Irb 6700 is designed to endure harsh industrial conditions, showcasing exceptional durability and reliability. Its robust construction, coupled with high-quality components, guarantees long-term performance and minimizes maintenance needs. This industrial robot is a cost-effective solution that offers a high return on investment, contributing to overall operational efficiency and profitability.

In summary, the Irb 6700 sets a new benchmark for industrial robots, thanks to its remarkable features and specifications. Its combination of cutting-edge technology, versatility, and safety measures ensures optimal productivity, efficiency, and reliability in various industrial applications.

Applications and Industries for the Irb 6700

The Irb 6700 robot, with its advanced features and capabilities, finds great utility across various applications and industries. Its versatility and precision make it an indispensable tool in modern automation systems.

Automotive Industry

The Irb 6700 plays a crucial role in the automotive industry, where it is utilized for tasks such as welding, material handling, and assembly operations. Its high payload capacity and exceptional accuracy enable efficient production processes, resulting in increased productivity and improved product quality.

Heavy Machinery Manufacturing

Heavy machinery manufacturing, including the production of equipment such as excavators, bulldozers, and cranes, benefits greatly from the capabilities of the Irb 6700. With its robust design and ability to handle large loads, the robot streamlines production processes, ensuring faster turnaround times and enhanced equipment reliability.

Additionally, the Irb 6700 is extensively employed in industries such as electronics, pharmaceuticals, and food and beverage. Its ability to operate in cleanroom environments, combined with its speed and precision, makes it suitable for tasks involving delicate components and stringent hygiene requirements.

In conclusion, the Irb 6700 is a versatile and efficient robot that finds extensive applications across various industries. Its advanced features and capabilities enable increased productivity, improved product quality, and efficient automation processes, making it an essential tool in the modern manufacturing landscape.

How the Irb 6700 is used in the automotive industry

The utilization of the Irb 6700 robotic system in the automotive sector has revolutionized manufacturing processes and significantly increased productivity. This state-of-the-art automation solution has become an integral part of various stages in automotive production, playing a crucial role in streamlining operations and enhancing overall efficiency.

One primary area where the Irb 6700 excels is in assembly line manufacturing. This cutting-edge robotic system handles intricate tasks with precision and speed, reducing human error and ensuring consistent quality. Its advanced technology enables it to execute complex movements, facilitating the flawless assembly of components and subassemblies.

Furthermore, the Irb 6700 is widely employed in material handling applications within the automotive industry. Equipped with robust motors and an efficient gripper, this versatile robot effectively moves heavy loads and transports materials with ease. Its ability to carry out repetitive tasks seamlessly contributes to optimized logistics and reduces the risk of manual handling injuries.

In addition, the Irb 6700 plays a vital role in the painting process of automobiles. With its exceptional accuracy and control, this robotic solution achieves consistent and high-quality paint finishes. By maintaining a precise spraying pattern and applying the optimal amount of paint, it ensures a flawless and uniform coating, enhancing the visual appeal of the vehicles.

Moreover, the Irb 6700 is instrumental in performing quality inspections. Equipped with advanced vision systems, this industrial robot is capable of quickly and accurately detecting defects, ensuring only flawless products reach the market. Its ability to meticulously analyze and inspect various components helps manufacturers maintain the highest standards of quality control.

In summary, the Irb 6700 has become an indispensable asset in the automotive industry. Its versatile capabilities in assembly line manufacturing, material handling, painting, and quality inspections have greatly optimized operations and enhanced the overall efficiency and quality of automotive production processes.

The role of the Irb 6700 in the manufacturing sector

In the fast-paced world of manufacturing, efficiency and precision are crucial for success. Companies constantly seek innovative solutions that can improve productivity while maintaining high-quality standards. One such solution that has revolutionized the industry is the Irb 6700. This advanced robotic system plays a vital role in streamlining manufacturing processes and optimizing productivity.

The Irb 6700 offers unparalleled flexibility and versatility, making it an indispensable asset in various manufacturing sectors. Its state-of-the-art features and capabilities empower businesses to automate repetitive and labor-intensive tasks, thereby reducing production time and costs. By seamlessly integrating with existing production lines, this robotic system enhances overall efficiency and ensures consistent output.

With its exceptional speed and accuracy, the Irb 6700 is capable of handling complex and intricate manufacturing tasks with ease. Equipped with advanced sensors and intelligent control systems, it can navigate complex environments, adapt to changing conditions, and perform precise movements. This not only improves production quality but also minimizes the risk of errors and accidents, resulting in a safer working environment.

- Enhanced productivity: The Irb 6700’s high-speed capabilities and seamless integration enable manufacturers to significantly increase production output, meet challenging deadlines, and fulfill customer demands effectively.

- Cost-efficiency: By automating repetitive tasks, the Irb 6700 reduces reliance on manual labor, leading to potential cost savings in the long run. Additionally, its accuracy minimizes material waste and rework, further optimizing manufacturing expenses.

- Improved quality control: With its precise movements and advanced sensors, the Irb 6700 ensures consistent production quality, reducing the chances of defects or inconsistencies. This ultimately enhances customer satisfaction and brand reputation.

- Workplace safety: By taking over hazardous or physically demanding tasks, the Irb 6700 minimizes the risk of workplace injuries. Its advanced safety features enable operators to work alongside the robotic system seamlessly, creating a harmonious man-machine collaboration.

In conclusion, the Irb 6700 plays a pivotal role in the manufacturing sector by boosting productivity, reducing costs, improving quality control, and enhancing workplace safety. Its advanced capabilities and seamless integration make it an invaluable asset to any manufacturing facility, driving innovation and success in a highly competitive industry.