Are you looking for a reliable and detailed resource that provides you with all the necessary information about a widely-used product? Look no further as we present to you an insightful guide that covers every aspect of the renowned Dow Corning 111 compound. Unveiling a comprehensive analysis without directly mentioning the specific terminology, this article will delve into the specifications and applications of a highly sought-after substance.

Within this informative document, find detailed insights into the technical properties of this remarkable compound. Delve into its unique features, such as its impressive thermal stability and outstanding resistance to oxidation. Explore the implications of its versatile performance, allowing for a wide range of applications across various industries. Uncover the intrinsic characteristics that make this compound stand out from its counterparts, enabling it to retain its efficacy even in highly demanding environments.

In addition to its exceptional performance characteristics, this guide also sheds light on the practical applications that Dow Corning 111 offers. Step into the world of crucial industries, from automotive and aerospace to electronics and construction, and discover how this compound plays a vital role. Explore the ways in which its extraordinary lubrication and sealing capabilities enhance the reliability and longevity of mechanical components. Gain valuable insights into its electrical insulation properties, ensuring optimal performance in delicate electronic devices.

Join us on this informative journey through this insightful document as we unravel the extensive information surrounding this highly sought-after compound. Whether you are an industry insider seeking in-depth knowledge or an enthusiast curious about the science behind it, this guide will empower you with a comprehensive understanding of the Dow Corning 111 compound, the applications it serves, and the benefits it can bring to various fields.

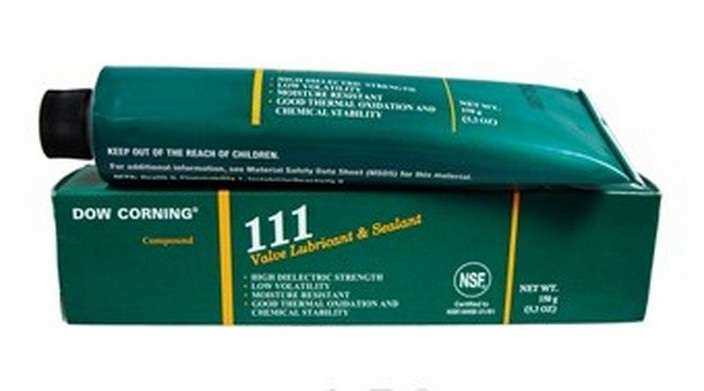

Dow Corning 111 Datasheet: Key Specifications and Features

The following section provides an overview of the essential characteristics and distinguishing attributes of the Dow Corning 111 product. This comprehensive datasheet is designed to provide key information to help users understand the unique specifications and features offered by this silicone compound.

Physical Properties:

One notable quality of the Dow Corning 111 compound is its exceptional stability under a wide range of operating conditions. This versatile substance demonstrates a remarkable resistance to various environmental factors, including extreme temperatures, moisture, and chemicals. Moreover, it exhibits superior adhesion and flexible properties, ensuring long-lasting performance.

Electrical Insulation:

With its excellent dielectric properties, the Dow Corning 111 silicone compound is primarily employed as an effective electrical insulator. It is able to withstand high voltages and prevent electrical leakage, making it an ideal choice for insulation applications. Furthermore, it provides reliable protection against electrical breakdown and is suitable for use in diverse electrical systems.

Thermal Conductivity:

The Dow Corning 111 compound also possesses impressive thermal conductivity properties, enabling efficient heat transfer. This attribute makes it highly desirable for applications that require effective thermal management, as it aids in dissipating heat and maintaining optimal operating temperatures. Its thermal conductivity allows for enhanced performance and prevents excessive heat accumulation.

Water Resistance:

A key feature of the Dow Corning 111 compound is its exceptional water resistance. This silicone compound effectively repels moisture, preventing it from penetrating or affecting the performance of the applied surface. Its water-repellent properties ensure reliable protection against moisture-related damage, making it suitable for use in various outdoor or wet environments.

Chemical Compatibility:

The Dow Corning 111 silicone compound is highly compatible with a wide range of chemicals, including gases, oils, and solvents. This quality enables its use in various industrial applications, where exposure to different chemical substances is common. It exhibits excellent resistance to chemical degradation, ensuring long-term durability and performance.

In conclusion, the Dow Corning 111 datasheet highlights the key specifications and features of this silicone compound. Its exceptional physical properties, electrical insulation capabilities, thermal conductivity, water resistance, and chemical compatibility make it a reliable and versatile choice for a multitude of applications.

Chemical Composition and Physical Properties

The section on Chemical Composition and Physical Properties provides an overview of the various constituents and characteristics of the product under discussion. It aims to offer insight into the makeup of the material and its corresponding physical attributes without explicitly mentioning its specific brand name or product code.

Key aspects examined in this section include the elemental composition of the substance, its molecular structure, and the chemical properties that define its behavior. Additionally, the physical properties such as viscosity, density, and temperature resistance are also explored, shedding light on the material’s ability to withstand different conditions and environments.

To further understand the composition and behavior of the product, it is essential to explore its characteristics in depth. The section may discuss the compound’s chemical bonds, molecular weight, and notable chemical reactions it may undergo. This knowledge helps users comprehend the substance’s potential applications, as well as its limitations, while maintaining a focus on broader chemical principles.

- Elemental composition: The elements present within the substance.

- Molecular structure: The arrangement and bonding between atoms.

- Chemical properties: The behavior and reactivity of the substance.

- Viscosity: The resistance to flow.

- Density: The mass per unit volume of the material.

- Temperature resistance: The ability to withstand high or low temperatures.

By providing a comprehensive overview of the chemical composition and physical properties, this section equips readers with a deeper understanding of the material’s structure and behavior. This knowledge forms the foundation for making informed decisions regarding its potential applications and compatibility in various contexts.

Applications and Benefits

The Applications and Benefits section of Dow Corning 111 focuses on the wide range of uses and advantages offered by this versatile product. It highlights the diverse fields where Dow Corning 111 can be applied, as well as the multitude of benefits it provides.

Various Applications: Dow Corning 111 finds applications across multiple industries and sectors, proving its versatility and adaptability. It is widely used in the automotive industry, electronics sector, and mechanical engineering field. Furthermore, this product is essential in the construction and maintenance of buildings, as well as in the manufacturing of medical devices.

Effective Lubrication: Dow Corning 111 boasts exceptional lubricating properties, enabling smooth movement and reducing friction. Its ability to create a thin yet durable layer of lubrication provides long-lasting protection for mechanical components, extending their lifespan and improving overall performance.

Superior Protection: With its excellent resistance to moisture, heat, and chemicals, Dow Corning 111 offers unmatched protection for various applications. It acts as a reliable sealant, preventing water, dust, and other contaminants from damaging sensitive equipment or components. Its high oxidation stability safeguards against degradation, ensuring prolonged durability and reliability.

Wide Temperature Range: Dow Corning 111 exhibits exceptional thermal stability, allowing it to perform consistently across a wide temperature range. Whether exposed to high heat or extreme cold, this product maintains its protective and lubricating properties, making it ideal for diversified applications in extreme environments.

Electrical Insulation: Due to its dielectric properties, Dow Corning 111 is widely utilized in electrical insulation applications. It forms a reliable barrier, preventing the flow of electricity and minimizing the risk of short circuits or electrical failures. Its exceptional dielectric strength ensures the safe and efficient operation of electrical systems.

Compatibility: Dow Corning 111 exhibits compatibility with various materials commonly used in different industries. It is compatible with metals, rubber, plastics, and elastomers, making it a versatile solution that can be used in a wide range of applications without concerns about material compatibility issues.

Long-Term Performance: With its excellent durability and performance, Dow Corning 111 ensures long-term reliability and effectiveness. Its superior properties allow for long-lasting protection and maintenance, reducing the need for frequent reapplication and minimizing downtime in various applications.

In conclusion, Dow Corning 111 offers an array of applications across diverse industries, providing numerous advantages such as effective lubrication, superior protection, wide temperature range, electrical insulation properties, compatibility with different materials, and long-term performance. Its versatility and reliability make it a valuable choice for professionals seeking a high-quality solution for their specific needs.

How to Use Dow Corning 111 for Optimum Results

When it comes to achieving the best performance and results with Dow Corning 111, it is important to understand the proper usage and techniques. This section provides valuable insights on how to make the most out of this product while avoiding common mistakes.

Preparation

- Before applying Dow Corning 111, ensure that the surface is clean and free from any contaminants or oils. Use an appropriate solvent to remove any existing residues.

- Make sure to dry the surface completely before applying the silicone compound. Any moisture left can impact the effectiveness of the product.

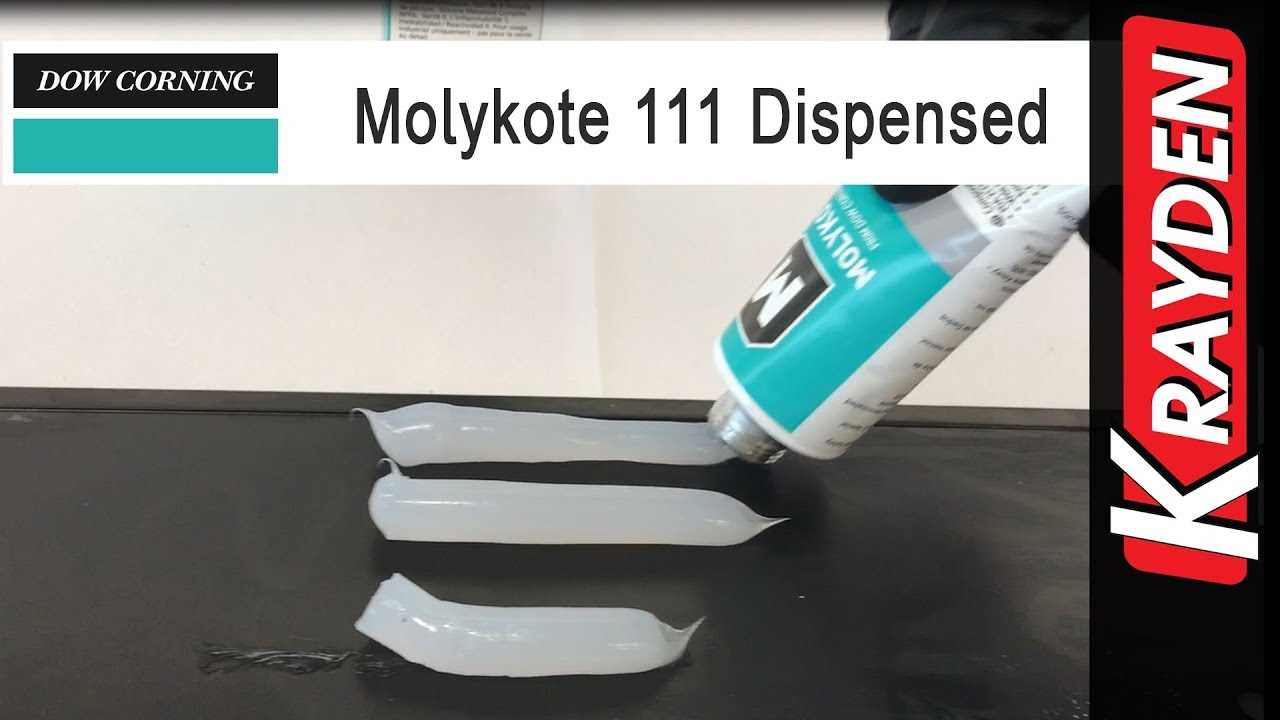

Application

- Take a small amount of Dow Corning 111 and apply it evenly to the desired area using a clean, lint-free cloth or brush. Avoid using an excessive amount to prevent wastage and ensure proper coverage.

- Using a gentle, circular motion, spread the compound across the surface, ensuring that it reaches all the necessary areas that require lubrication or sealing.

Curing

- Allow Dow Corning 111 to cure naturally at room temperature. The curing time may vary depending on the application, but typically it takes around 24 hours to fully cure.

- Avoid exposing the product to extreme temperatures or moisture during the curing process, as this can affect the integrity of the seal or lubrication.

By following these guidelines, you can ensure that Dow Corning 111 delivers optimum results. Remember to always refer to the specific application requirements and consult the product’s technical datasheet for comprehensive instructions and safety precautions.