In the world of metallurgy, there exists a remarkable alloy that offers a range of desirable properties for many applications. This alloy, frequently referred to as the “versatile stainless steel,” is known by its European grade designation 1.4404. It is a highly sought-after material in various industries due to its exceptional corrosion resistance, excellent formability, and impressive mechanical strength.

Often hailed as a synonym of reliability and durability, this stainless steel alloy proves its worth across a wide range of environments and conditions. Whether it is facing harsh chemicals, high temperatures, or extreme weather, it stands strong, offering long-lasting performance. Its remarkable ability to resist corrosion ensures that structures and components made from this alloy retain their integrity and functionality over extended periods.

Notably, the alloy’s versatility is not limited to its corrosion resistance. It exhibits excellent formability, making it highly suitable for various shaping and fabrication processes. Manufacturers and engineers can effortlessly transform it into complex shapes, resulting in intricate and precise components. Furthermore, this material possesses exceptional mechanical strength, allowing it to withstand substantial loads and pressures without compromising its integrity.

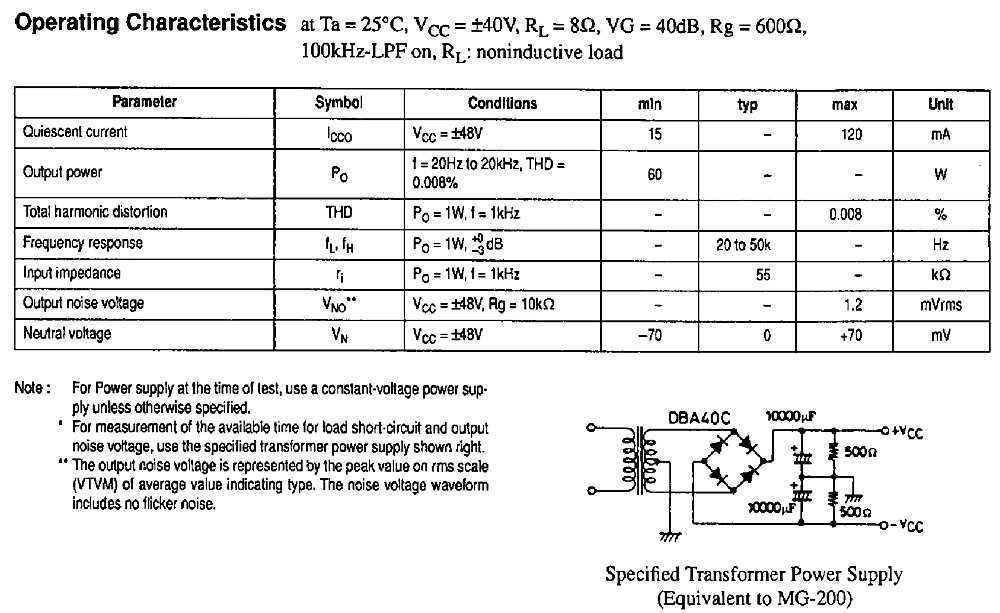

With all these remarkable attributes, it is no wonder that the material’s datasheet is often sought after by professionals in several industries. By familiarizing themselves with the technical specifications outlined in the datasheet, engineers can confidently select and utilize this versatile stainless steel alloy to meet the specific requirements of their projects. In the next sections, we will delve into the various properties, composition, and applications of this alloy, providing an in-depth understanding of its capabilities.

Understanding the composition and characteristics

Exploring the intricacies of alloy 1.4404 entails delving into its distinct composition and notable properties. This section aims to shed light on the key factors that contribute to the unique nature of this material.

Composition:

At its core, alloy 1.4404 is a complex combination of different elements, carefully engineered to exhibit remarkable attributes. It comprises a high percentage of chromium and nickel, which contribute to its exceptional corrosion resistance, making it ideal for various applications in challenging environments. Additionally, this material also contains a precise amount of molybdenum, enhancing its resistance against pitting and crevice corrosion.

Characteristics:

Unveiling the characteristics of alloy 1.4404 sheds light on its versatility and suitability for diverse industries. One of its remarkable features is its robust mechanical properties, including high tensile strength and excellent toughness. Furthermore, its low carbon content ensures superior weldability without compromising its corrosion resistance, making it a favored choice in fabrication processes. Additionally, the material’s resistance to oxidation and scaling even at elevated temperatures further amplifies its appeal.

Moreover, alloy 1.4404’s exceptional formability lends itself to various shaping techniques, allowing manufacturers to produce intricate components with ease. Its exceptional machinability facilitates efficient manufacturing processes, reducing production time and costs. Lastly, its aesthetic appeal, combined with its durability, makes it a preferred material in architectural and decorative applications.

Understanding the composition and characteristics of alloy 1.4404 is crucial in harnessing its full potential across numerous industries, ensuring reliable and long-lasting solutions for a multitude of applications.

Applications and benefits of Material 1.4404

In this section, we will explore the various applications and advantages of Material 1.4404, a corrosion-resistant stainless steel alloy widely used in various industries.

1. Versatile Applications

Material 1.4404 finds extensive use across a wide range of industries thanks to its exceptional properties and versatility. Its resistance to corrosion, high temperatures, and chemicals makes it suitable for applications in the chemical, petrochemical, and pharmaceutical industries.

The alloy’s durability and strength also make it highly suitable for use in marine environments, where it is used in the construction of ship fittings, offshore structures, and desalination plants. Additionally, Material 1.4404 finds application in the food and beverage industry, as it is non-reactive with various food and drink substances.

2. Advantages of Material 1.4404

Material 1.4404 offers numerous advantages that contribute to its popularity in different industrial sectors.

| Advantage | Description |

|---|---|

| Corrosion Resistance | The alloy exhibits outstanding resistance to corrosion, including pitting and crevice corrosion, even in aggressive environments containing chlorides and acids. |

| High Strength | Material 1.4404 possesses excellent mechanical properties, including high tensile strength and good yield strength, offering reliability and durability in various applications. |

| Heat Resistance | With its ability to withstand elevated temperatures, Material 1.4404 is suitable for applications where exposure to high heat is common, such as heat exchangers and exhaust systems. |

| Machinability | Despite its high strength and corrosion resistance, Material 1.4404 is still easily machinable, allowing for efficient fabrication and production processes. |

| Hygienic Properties | The alloy’s non-porous and smooth surface makes it easy to clean and maintain, meeting the stringent hygiene requirements of industries such as food processing and pharmaceutical manufacturing. |

In conclusion, Material 1.4404 is a versatile stainless steel alloy that finds applications in a wide range of industries. Its exceptional corrosion resistance, high strength, heat resistance, machinability, and hygienic properties make it a preferred choice for various demanding environments and critical applications.

Important considerations when working with 1.4404 stainless steel

When utilizing this high-quality stainless steel material, there are several crucial factors that must be taken into account to ensure optimal performance and longevity. By paying careful attention to these considerations, users can maximize the benefits of 1.4404 stainless steel while avoiding potential challenges that may arise during its usage.

- Compatibility with corrosive environments: Due to its excellent corrosion resistance properties, 1.4404 stainless steel is well-suited for applications in various corrosive environments. However, it is crucial to assess the specific conditions of the environment in which the material will be exposed. Factors such as temperature, humidity, and chemical composition should be considered to ensure the stainless steel’s lasting performance and prevent any potential corrosion-related issues.

- Temperature variations: 1.4404 stainless steel exhibits excellent mechanical properties over a wide range of temperatures. However, it is essential to understand the material’s limitations in extreme temperature conditions. High temperatures can affect the material’s mechanical strength and corrosion resistance, while low temperatures can impact its toughness. Therefore, conducting thorough temperature assessments is critical to ensure the material’s suitability for the intended application.

- Surface finish requirements: The surface finish of 1.4404 stainless steel can significantly impact its performance and appearance. Different industries and applications often have specific surface finish requirements to meet functional and aesthetic expectations. It is important to carefully evaluate these requirements and select the appropriate finishing method to achieve the desired outcome.

- Welding considerations: Welding is a common process when working with 1.4404 stainless steel. However, specific considerations must be taken into account to maintain the material’s integrity during welding operations. Factors such as filler material selection, welding techniques, and post-welding treatments should be carefully evaluated to avoid the formation of unwanted defects, such as sensitization or intergranular corrosion.

- Maintenance and cleaning practices: To ensure the longevity and performance of 1.4404 stainless steel, proper maintenance and cleaning practices should be implemented. Regular cleaning using mild detergents and non-abrasive methods can help remove contaminants and prevent the build-up of deposits on the material’s surface. Additionally, avoiding exposure to chlorides and other aggressive chemicals is essential to prevent potential corrosion issues.

By considering these important factors when working with 1.4404 stainless steel, users can harness the material’s advantageous properties and minimize the risk of any potential challenges. Careful evaluation, adherence to industry standards, and proper maintenance practices can contribute to the successful utilization of this durable and versatile stainless steel in various applications.