When it comes to designing and constructing high-performance machinery, mastering the selection of reliable and durable materials is key. Whether you are an experienced engineer or just starting to explore the world of industrial-grade components, understanding the benefits of innovative materials, such as Nylatron 703XL, can greatly impact the success of your projects.

Engineered with precision and driven by excellence, Nylatron 703XL stands out as a remarkable solution that delivers superior performance in various applications. This versatile material exhibits exceptional strength, outstanding wear resistance, and remarkable dimensional stability, making it ideal for high-load and high-friction environments.

Unleash your creativity and elevate your designs with Nylatron 703XL – a material that pushes the boundaries of engineering possibilities. With its unique combination of strength, self-lubricating properties, and exceptional resistance to wear, Nylatron 703XL continues to revolutionize industries and exceed expectations.

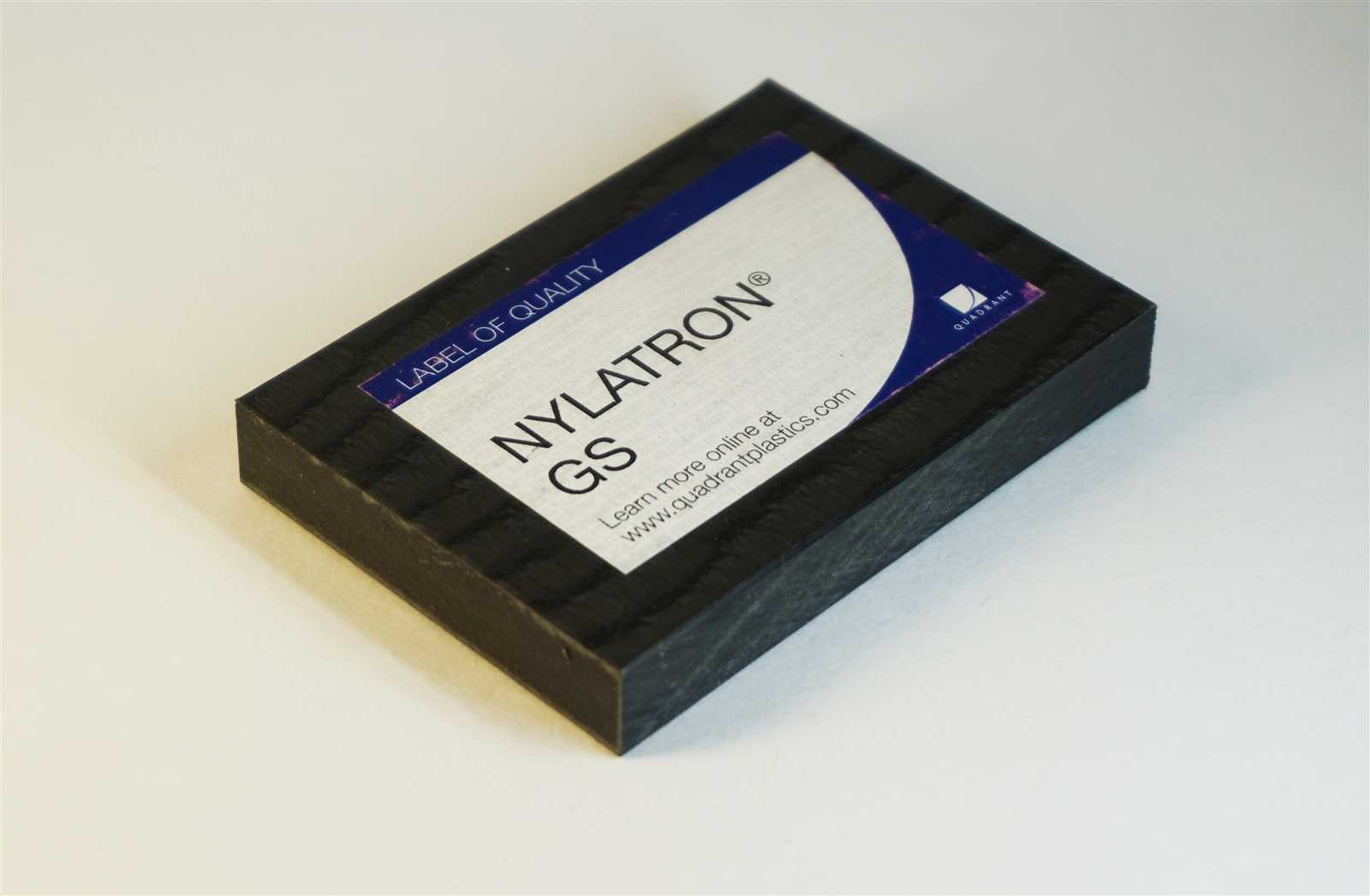

Nylatron 703xl: Overview and Key Features

When it comes to high-performance materials for industrial applications, Nylatron 703xl stands out as a reliable and durable option. This advanced thermoplastic material offers a range of key features that make it ideal for a variety of industries and applications.

Superior Strength and Durability

- Exceptional tensile strength

- Excellent resistance to wear and tear

- Outstanding impact resistance

One of the most notable characteristics of Nylatron 703xl is its superior strength and durability. With its exceptional tensile strength, this material can withstand heavy loads and high stress environments. Additionally, it offers excellent resistance to wear and tear, ensuring that it can endure even the harshest conditions. The outstanding impact resistance of Nylatron 703xl further enhances its durability, making it a reliable choice for demanding applications.

Excellent Machinability

- Easy to machine

- Precision machining capabilities

- Reduced machining time and cost

In addition to its strength and durability, Nylatron 703xl boasts excellent machinability. This thermoplastic material is easy to machine, allowing for precise shaping and customization according to specific requirements. Its precision machining capabilities ensure high dimensional accuracy, making it suitable for applications that demand tight tolerances. Moreover, the reduced machining time and cost associated with Nylatron 703xl contribute to improved efficiency and cost-effectiveness.

Chemical and Moisture Resistance

- Resistance to a wide range of chemicals

- Excellent moisture resistance

- Minimal absorption of fluids

Another key feature of Nylatron 703xl is its exceptional resistance to various chemicals and moisture. This thermoplastic material demonstrates resistance to a wide range of chemicals, ensuring its integrity and performance even in corrosive environments. Additionally, it exhibits excellent moisture resistance, making it suitable for applications exposed to humid or wet conditions. The minimal absorption of fluids by Nylatron 703xl further enhances its stability and longevity.

In conclusion, Nylatron 703xl is a high-performance thermoplastic material that offers superior strength and durability, excellent machinability, and exceptional resistance to chemicals and moisture. These key features make it an ideal choice for a wide range of industrial applications where reliability and longevity are crucial.

Key Benefits and Applications of Nylatron 703xl

Nylatron 703xl is a highly versatile material that offers a wide range of benefits and finds applications in various industries. This section aims to highlight the key advantages and uses of Nylatron 703xl, without directly mentioning its name or specific technical details.

1. Exceptional Durability and Strength

One of the notable advantages of this advanced material is its exceptional durability and strength. Its robust composition enables it to withstand heavy loads and resist wear and tear, ensuring long-lasting performance in demanding applications.

2. Superior Lubricity and Friction Reduction

Another key benefit of Nylatron 703xl is its superior lubricity properties, which help reduce friction and enhance the efficiency of mechanical systems. By minimizing frictional losses, this material promotes smoother operations and reduces the need for frequent maintenance.

3. Chemical Resistance

Nylatron 703xl exhibits excellent resistance to a wide range of chemicals, making it suitable for use in environments where exposure to aggressive substances is a concern. Its ability to withstand harsh chemical agents contributes to its overall durability and extends its lifespan.

4. Thermal Stability and Heat Resistance

This high-performance material maintains its integrity even under high temperatures, exhibiting exceptional thermal stability and heat resistance. It can withstand demanding thermal environments without deforming or losing its mechanical properties, ensuring reliable performance in extreme conditions.

5. Wide Range of Applications

Due to its versatile nature, Nylatron 703xl finds applications across various industries. It is commonly used in the manufacturing of components for machinery, automotive parts, electrical insulators, and gears. Its unique combination of properties makes it an ideal choice for applications that require strength, durability, and chemical resistance.

- Machinery manufacturing

- Automotive industry

- Electrical equipment

- Gear production

In conclusion, the key benefits and applications of the advanced material known as Nylatron 703xl are its exceptional durability, superior lubricity, chemical resistance, thermal stability, and its wide range of uses across industries. Its unique properties make it a highly sought-after material for applications demanding strength, durability, and resistance to harsh environments.

Nylatron 703xl Technical Data and Specifications

In this section, we will explore the technical data and specifications of a high-performance engineering plastic known as Nylatron 703xl. This material offers exceptional strength, durability, and versatility, making it an ideal choice for various applications. By understanding its properties, users can make informed decisions regarding the suitability of Nylatron 703xl for their specific needs.

Physical Properties

One of the key aspects to consider when evaluating Nylatron 703xl is its physical properties. This includes its density, which determines its weight and volume ratio, as well as its hardness, which refers to its resistance to indentation or scratching. Additionally, the material’s color, typically a dark shade of blue, contributes to its aesthetic appeal.

Furthermore, it is important to take into account Nylatron 703xl’s dimensional stability, which refers to its ability to retain its shape and size under different environmental conditions. This is particularly relevant in applications where tight tolerances are required.

Mechanical Properties

The mechanical properties of Nylatron 703xl play a crucial role in determining its performance and reliability. These properties include its tensile strength, which measures its ability to withstand pulling or stretching forces, as well as its impact resistance, which indicates its ability to withstand sudden shocks or collisions.

In addition, the material’s flexural modulus and elongation at break provide insights into its stiffness and ability to deform without breaking under strain. These properties are essential considerations for applications where Nylatron 703xl will be subjected to bending or flexing forces.

Furthermore, the material’s coefficient of friction and wear resistance are vital in applications where low friction and high durability are desired. These properties ensure that Nylatron 703xl can withstand sliding or rubbing against other surfaces without excessive wear or damage.

Lastly, the material’s thermal properties, including its melting point, thermal conductivity, and heat deflection temperature, are crucial for applications that involve exposure to high temperatures or thermal cycling.

In conclusion, understanding the technical data and specifications of Nylatron 703xl is essential for assessing its suitability for various applications. By considering its physical properties, mechanical properties, and thermal properties, users can make informed decisions about utilizing Nylatron 703xl in their projects, ensuring optimal performance and longevity.