Discovering the essence of innovation

Exploring the realm of modern electronic components is akin to embarking on a journey into the heart of innovation. Within this ever-evolving landscape, each component holds the promise of unlocking new possibilities, propelling industries forward with unprecedented efficiency and performance.

Delving into the intricacies of these technological marvels reveals a world where precision meets ingenuity, where circuits intertwine to form the backbone of tomorrow’s advancements.

Amidst this dynamic environment, one finds a particular component, a cornerstone of connectivity and functionality, whose intricacies and capabilities remain shrouded in the allure of discovery.

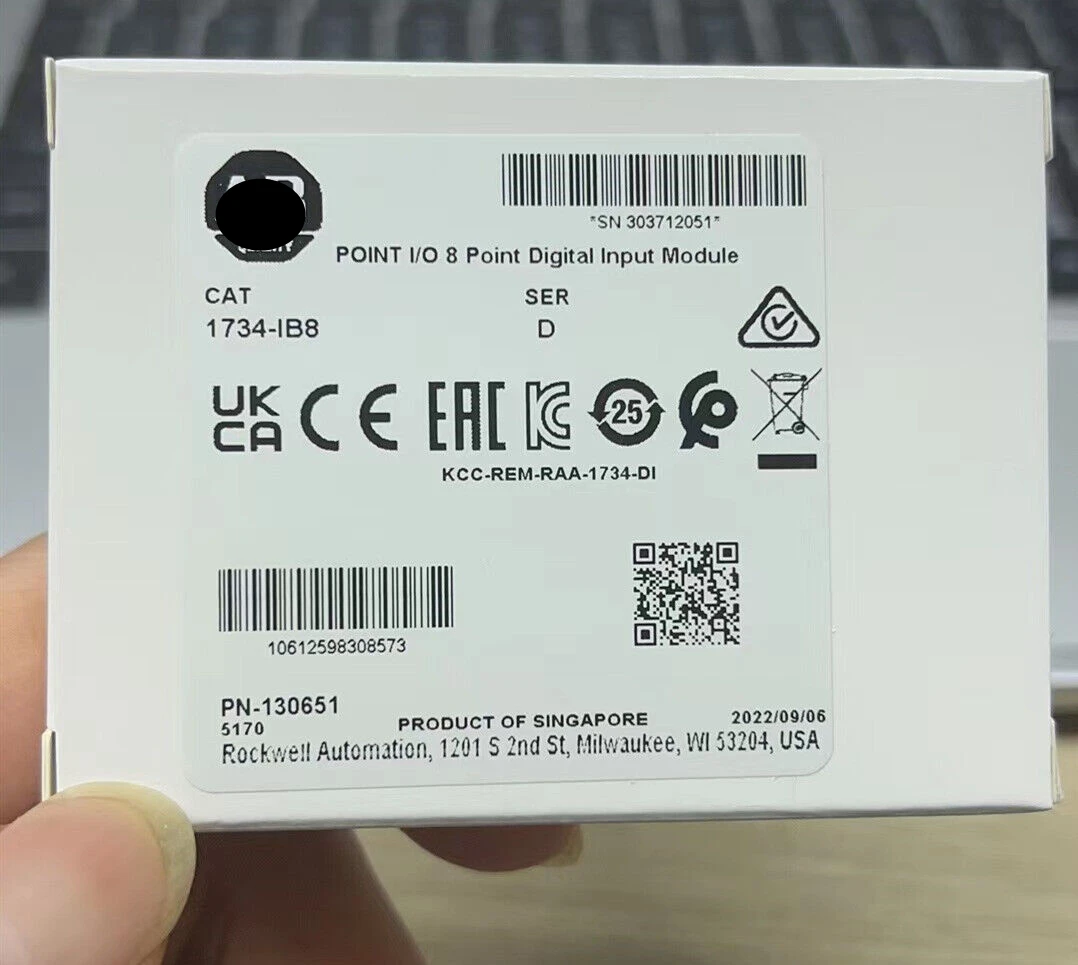

Exploring the Characteristics of 1734-IB8 Documentation

In this segment, we delve into the intricacies and functionalities encapsulated within the documentation of the 1734-IB8 module. Unveiling its myriad features, we navigate through the comprehensive details, elucidating its capabilities and applications.

Unveiling Functionality: Within this documentation, a plethora of functionalities awaits exploration, each designed to cater to diverse industrial requirements. From input specifications to operational guidelines, this documentation serves as a roadmap for seamless integration and utilization.

Understanding Operational Parameters: Embedded within the documentation are insights into the operational parameters governing the performance of the module. Through meticulous examination, users gain a nuanced understanding of the module’s behavior, enabling informed decision-making and precise configuration.

Exploring Compatibility: Beyond mere functionality, the documentation illuminates the compatibility matrix, elucidating the module’s interoperability with a spectrum of industrial setups. This section serves as a guide for system architects and integrators, ensuring seamless integration within existing frameworks.

Unlocking Application Insights: Within the depths of this documentation lie valuable insights into application scenarios and use cases. Through real-world examples and case studies, users garner a deeper understanding of the module’s utility across diverse industrial landscapes.

Embracing Best Practices: Complementing its technical specifications, the documentation espouses best practices and recommendations for optimal utilization. From installation guidelines to maintenance protocols, users are equipped with the knowledge necessary for maximizing the module’s efficiency and longevity.

Navigating Troubleshooting Resources: In the event of operational hiccups, the documentation serves as a repository of troubleshooting resources. Armed with diagnostic procedures and fault resolution strategies, users can swiftly address issues, minimizing downtime and optimizing productivity.

In conclusion, the documentation of the 1734-IB8 module transcends mere technicalities, embodying a comprehensive guide for users to unlock its full potential. Through diligent exploration and application, users harness its capabilities to propel their industrial endeavors towards efficiency and success.

Understanding Input/Output Modules

In the realm of industrial automation, the backbone of control systems lies in the efficient management of inputs and outputs. These modules serve as the vital interface between the physical world of sensors and actuators and the digital realm of controllers and processors. By seamlessly translating analog and digital signals into a language comprehensible to the control system, these modules enable precise monitoring and control of various industrial processes.

Input/output modules, often referred to as I/O modules, facilitate the exchange of information between the field devices and the central control unit. They play a crucial role in gathering data from sensors dispersed throughout the operational environment and delivering commands to actuators, thereby orchestrating the desired response. This intermediary function ensures smooth communication flow, enabling real-time decision-making and control within industrial settings.

- Input Modules: These modules are tasked with acquiring data from sensors monitoring parameters such as temperature, pressure, flow, and proximity. They convert these analog or digital signals into a format interpretable by the control system, providing vital insights into the operational state of the machinery or process.

- Output Modules: Conversely, output modules receive instructions from the control system and translate them into actions executed by actuators. Whether it’s activating motors, solenoids, valves, or other output devices, these modules ensure that the control commands are effectively implemented in the physical world.

- Communication Protocols: Modern I/O modules support various communication protocols, facilitating seamless integration with diverse control systems. Whether employing Ethernet/IP, Profibus, Modbus, or other industry-standard protocols, these modules ensure interoperability and compatibility across different automation platforms.

- Scalability and Flexibility: A hallmark of contemporary I/O modules is their scalability and flexibility, allowing for modular expansion and customization according to the specific requirements of the industrial application. This adaptability empowers businesses to optimize their control systems efficiently as their operational needs evolve.

- Diagnostic Capabilities: Advanced input/output modules often incorporate diagnostic features, enabling proactive monitoring of field devices and communication channels. By detecting faults, anomalies, or signal disruptions in real-time, these modules facilitate predictive maintenance and minimize downtime, thereby enhancing overall system reliability.

In essence, input/output modules serve as the indispensable link between the physical world of industrial processes and the digital realm of control systems. By facilitating seamless communication, translating signals, and ensuring compatibility, these modules empower organizations to achieve heightened efficiency, reliability, and responsiveness in their automation endeavors.

Key Specifications and Performance Metrics

In this section, we delve into the essential characteristics and operational parameters that define the functionality and efficacy of the component under scrutiny. We explore the quantitative measures and qualitative attributes that encapsulate its performance and capabilities, shedding light on its potential applications and operational nuances.

Performance Parameters Overview

Before delving into the specifics, it’s paramount to grasp the overarching performance parameters that underpin the functionality of the component. These metrics encompass factors such as efficiency, accuracy, speed, and reliability, each playing a pivotal role in determining the device’s suitability for various industrial contexts.

- Input and Output Specifications: The range and types of signals accommodated by the component, including voltage levels, current ratings, and signal types.

- Operational Characteristics: Insights into the device’s response time, latency, and throughput, elucidating its real-time processing capabilities.

- Environmental Considerations: Factors such as temperature range, humidity tolerance, and susceptibility to external interference, influencing the component’s performance in diverse environmental conditions.

- Functional Integrity: The robustness of the component’s design, its resistance to wear and tear, and adherence to industry standards, ensuring consistent and reliable operation over its lifespan.

Key Specifications

Now, let’s delve into the specific metrics that serve as benchmarks for evaluating the component’s performance and efficacy in practical applications. These specifications encompass both electrical and operational parameters, providing a comprehensive overview of the component’s capabilities.

- Input Voltage Range: The minimum and maximum voltage levels accepted by the component for seamless operation.

- Output Current Capacity: The maximum current that the component can deliver to connected devices without compromising performance.

- Response Time: The duration taken by the component to react to input signals and produce corresponding output signals, influencing its real-time responsiveness.

- Accuracy and Precision: Measures of the component’s ability to deliver precise outputs under varying input conditions, crucial for applications demanding high levels of precision.

- Reliability Metrics: Indicators of the component’s reliability, including mean time between failures (MTBF) and failure rate, crucial for minimizing downtime and maintenance costs.

By scrutinizing these key specifications and performance metrics, stakeholders can gain invaluable insights into the capabilities and limitations of the component, facilitating informed decision-making and optimal utilization in diverse industrial settings.

Integration and Compatibility Considerations

When incorporating the device specified in the document labeled as 1734-ib8, it is imperative to assess its seamless integration and compatibility within existing systems. This section delves into crucial factors to contemplate during the integration process, ensuring harmonious operation without impedance or conflicts.

- Interface Adaptability: Understanding the interface nuances and ensuring compatibility with the prevailing system architecture is paramount. Compatibility hinges on the ability of the device to seamlessly communicate and synchronize with the existing components.

- Protocol Conformity: Assessing whether the device adheres to standard protocols prevalent in the system is essential. Compatibility issues may arise if the device employs proprietary protocols conflicting with the established standards.

- Power Supply Alignment: Ensuring the power requirements of the device align with the available power infrastructure is critical. Compatibility issues may emerge if the device necessitates power specifications beyond the capacity of the existing setup.

- Form Factor Suitability: Evaluating the physical dimensions and mounting requirements of the device in comparison to available space is vital. Compatibility concerns may surface if the device’s form factor does not align with the spatial constraints of the installation environment.

- Software Integration: Assessing compatibility with the software ecosystem is imperative for seamless operation. Compatibility challenges may arise if the device requires specialized software or lacks support for prevalent operating systems.

- Environmental Compatibility: Considering the environmental conditions within which the device will operate is crucial. Compatibility issues may arise if the device is not designed to withstand temperature fluctuations, moisture, or other environmental variables present in the installation environment.

By meticulously evaluating these integration and compatibility considerations, stakeholders can preemptively address potential challenges and ensure the smooth assimilation of the device into the existing system framework.