Delving into the intricate realms of adhesive formulation intelligence, we embark on a journey through the labyrinth of material intricacies. Behind the curtain of technical intricacy lies a treasure trove of insights, a compendium meticulously crafted to unveil the arcane secrets of chemical synergy. Here, amidst the labyrinth of alphanumeric codes and cryptic symbols, lies a gateway to understanding, a portal to mastery.

In this realm of meticulous detail and structured clarity, each page serves as a roadmap through the terrain of industrial alchemy. Words, carefully selected and meticulously arranged, weave a narrative of functionality and resilience. It’s a lexicon of possibilities, a symphony of bonding potential, waiting to be deciphered by those who dare to delve deeper.

Within these pages, lies the blueprint of cohesion, where polymers dance in harmonic unison, and surfaces find solace in each other’s embrace. It’s a manifesto of adhesion, a testament to the triumph of science over separation. Through the lens of comprehension, what may seem mundane transforms into a tapestry of innovation and progress.

Understanding the Composition of Loctite 408

In this section, we delve into the intricate formulation of the adhesive product known for its versatile bonding capabilities. Exploring its elemental makeup provides insights into its adhesive properties and application range.

- Chemical Components: An exploration of the chemical constituents reveals the foundation of its adhesive strength.

- Molecular Structure: Understanding the arrangement of molecules elucidates the bonding mechanism, highlighting its efficacy in various environments.

- Functional Groups: Examining the functional groups unveils the specific interactions facilitating adhesion, ensuring reliability in diverse conditions.

- Curing Agents: Insight into the agents responsible for the curing process elucidates the transformation from liquid to solid, crucial for durable bonds.

- Additives: Analysis of additional components unveils enhancements tailored to specific applications, enhancing performance characteristics.

By comprehending the composition of this adhesive, users gain a deeper appreciation of its capabilities and suitability for a myriad of bonding needs.

The Chemical Ingredients Unveiled

Exploring the constituents of the adhesive solution under scrutiny reveals a nuanced blend of compounds carefully calibrated to deliver optimal performance. This elucidation delves into the intricate composition of the substance, shedding light on its fundamental building blocks and their collective role in achieving adhesive prowess.

Key Components

At the heart of this adhesive formulation lie a series of elemental constituents, each playing a distinct role in the adhesive’s functionality. These components, when combined, form a synergistic matrix that imbues the adhesive with its remarkable properties.

Primer Agents: Initiating the bonding process, primer agents prepare surfaces for adhesion by promoting molecular interaction and enhancing surface energy.

Polymer Resins: Serving as the backbone of the adhesive, polymer resins provide structural integrity and contribute to the adhesive’s strength and flexibility.

Curing Agents: Facilitating the cross-linking of polymers, curing agents catalyze the hardening process, ensuring durable and resilient bonds.

Functional Dynamics

Understanding the interplay between these chemical constituents unveils the intricate dynamics governing adhesive behavior. Through a delicate balance of affinity, reactivity, and molecular structure, the adhesive achieves optimal adhesion, exhibiting superior performance across a spectrum of applications.

Properties and Applications Explored

In this section, we delve into the diverse characteristics and potential uses of the adhesive compound under discussion. Through an analysis of its various attributes and functionalities, we uncover the versatility and practicality it offers across multiple scenarios and industries.

| Property | Exploration |

|---|---|

| Adhesion | Examining its ability to firmly bond diverse materials, enhancing structural integrity. |

| Viscosity | Exploring the flow properties, crucial for precision applications and gap filling. |

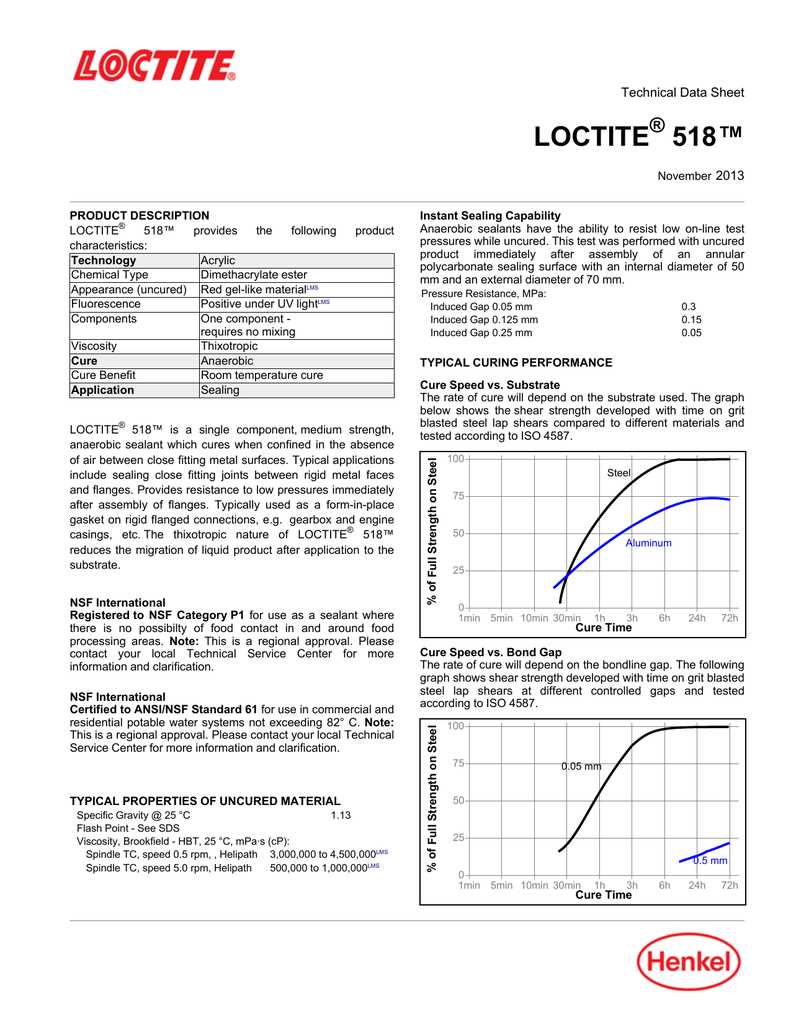

| Curing Mechanism | Analyzing the curing process, determining its speed and compatibility with substrates. |

| Chemical Resistance | Investigating its resilience against various chemicals and environmental factors, ensuring durability in harsh conditions. |

| Temperature Stability | Assessing its performance under extreme temperatures, vital for applications in diverse climates. |

| Electrical Insulation | Evaluating its ability to provide insulation, crucial in electronic and electrical applications. |

| Flexibility | Examining its flexibility, determining suitability for dynamic or moving parts. |

Furthermore, we explore the array of industries and applications where this adhesive compound can be effectively utilized, ranging from automotive assembly lines to intricate electronics manufacturing, showcasing its adaptability and reliability.

Application Guidelines for Product 408

Within this section, we will outline comprehensive guidelines to facilitate the effective utilization of Product 408. Understanding the optimal methods of application is paramount in ensuring the efficacy and durability of this adhesive. Through adherence to these guidelines, users can maximize the potential of the product, achieving superior bonding results across various substrates and applications.

Surface Preparation

Proper preparation of surfaces is fundamental to the success of adhesive application. Prior to bonding, it is imperative to meticulously clean and degrease the surfaces intended for bonding. This process eliminates contaminants and ensures maximum adhesion strength.

Application Techniques

Employing appropriate application techniques is crucial for achieving optimal results with Product 408. Whether applying by hand or utilizing automated systems, it is essential to maintain uniformity and precision throughout the process. Additionally, controlling adhesive bead size and placement is key to avoiding excessive adhesive consumption and ensuring adequate coverage.

Throughout the application process, it is advisable to monitor environmental conditions such as temperature and humidity, as these factors can influence curing times and bond strength. Moreover, exercising caution to prevent skin contact and utilizing proper ventilation in confined spaces are essential safety measures to observe during application.

Optimal Usage Conditions

In this section, we delve into the ideal circumstances for utilizing the substance effectively. It’s imperative to comprehend the environmental and situational factors that contribute to the optimal application of the product. By aligning with these conducive conditions, users can maximize the efficiency and effectiveness of its utilization.

Environmental Considerations:

Environmental variables play a pivotal role in ensuring the efficacy of the substance. Factors such as temperature, humidity, and air circulation significantly influence its performance. Understanding and controlling these elements are paramount to achieving optimal results.

Application Setting:

The setting in which the substance is applied greatly impacts its functionality. Whether it’s within an industrial facility, a manufacturing plant, or a household environment, each setting presents unique challenges and opportunities. Adhering to recommended application procedures tailored to the specific setting enhances the product’s performance.

Surface Preparation:

Surface preparation is a critical precursor to the application process. Proper cleaning, degreasing, and roughening of surfaces ensure maximal adhesion and bond strength. Attention to detail during this stage is essential for achieving the desired outcomes.

Application Technique:

The technique employed during application significantly affects the final result. Whether it’s through manual application, automated dispensing, or other methods, employing the correct technique ensures uniform coverage and optimal bond formation.

Post-Application Conditions:

After application, the product requires specific post-application conditions to facilitate curing and setting. Factors such as curing time, temperature, and environmental exposure must be carefully monitored to achieve the desired bond strength and durability.

Regular Monitoring and Maintenance:

Once applied, regular monitoring and maintenance are essential to ensure continued effectiveness. Periodic inspections, upkeep, and adherence to recommended maintenance practices prolong the lifespan and functionality of the bonded surfaces.

By adhering to these optimal usage conditions, users can harness the full potential of the substance, achieving robust and reliable bonds across diverse applications.