Embarking on a journey through the intricacies of a specific electrical apparatus, one encounters a realm where numbers and symbols converge to unveil the capabilities and limitations of a technological marvel. In this exploration, we delve into the blueprint of a device pulsating with energy, deciphering its essence through a labyrinth of specifications and performance metrics.

Within the confines of technical documentation, lies a treasure trove of information, guiding engineers and enthusiasts alike through the nuances of electrical engineering. As we navigate through the corridors of this datasheet, we espy the language of voltage, current, and efficiency, each term painting a vivid picture of the prowess encapsulated within the confines of a 12-volt dynamo.

With each line of text, a story unfolds, narrating the capabilities of a compact powerhouse, beckoning the curious to decipher its cryptic language. Beyond the mere numbers, lies a tale of innovation and ingenuity, waiting to be unveiled by those daring enough to venture into the realm of technical literature.

Understanding DC 12 Volt Motor Specifications

In the realm of electrical machinery, there exists a dynamic interplay of factors that define the performance and capabilities of DC motors operating at 12 volts. Delving into the intricacies of these specifications unveils a landscape where power, efficiency, and functionality converge to dictate the motor’s behavior within diverse applications.

Power Output and Efficiency

Power output stands as a pivotal metric, reflecting the motor’s ability to convert electrical energy into mechanical work. It encapsulates the force and speed at which the motor operates, influencing its performance across various tasks. Concurrently, efficiency delineates the motor’s proficiency in utilizing input power, shedding light on its energy conservation capabilities.

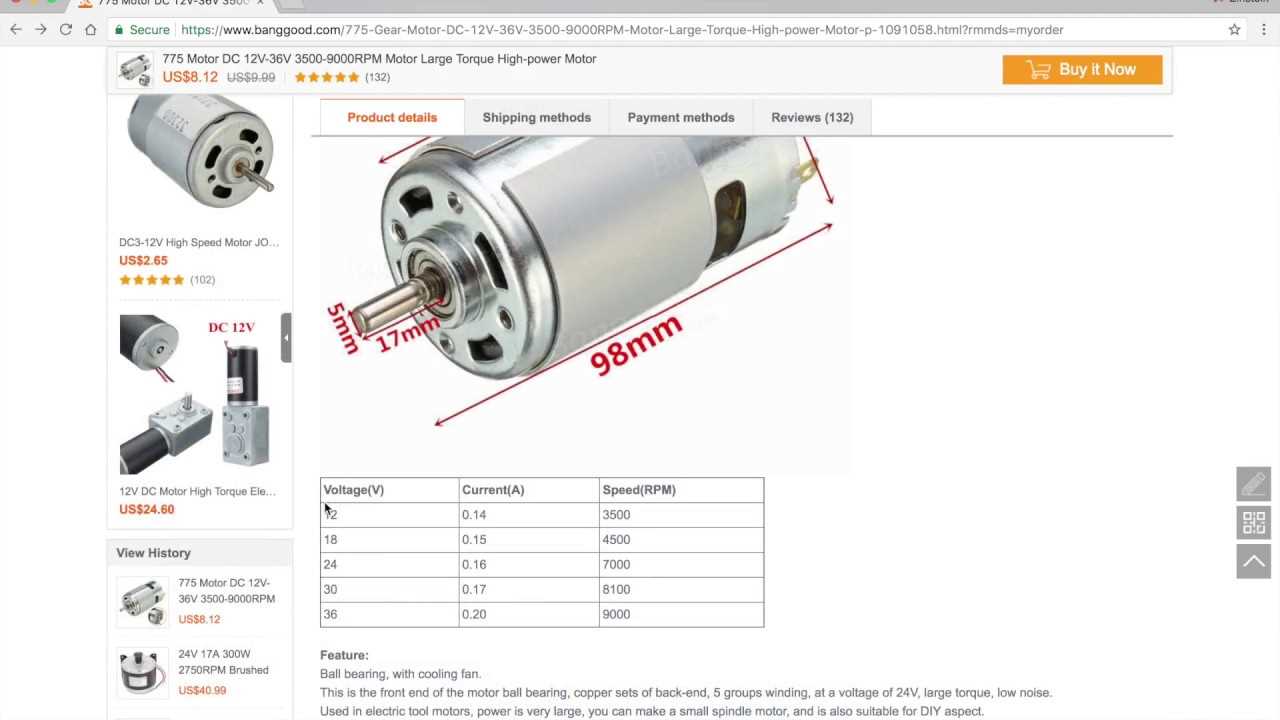

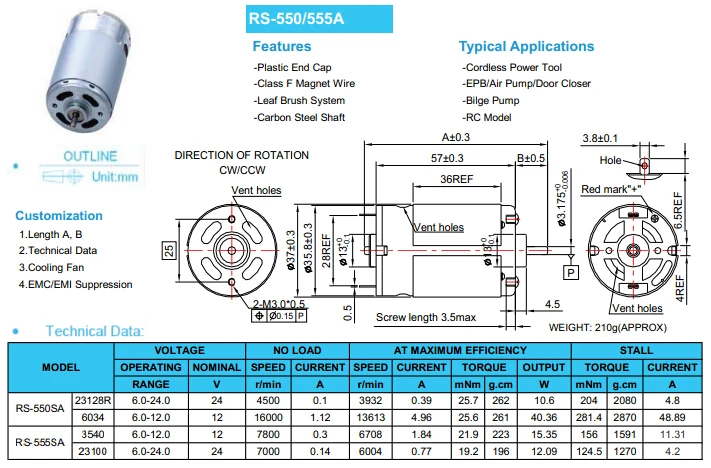

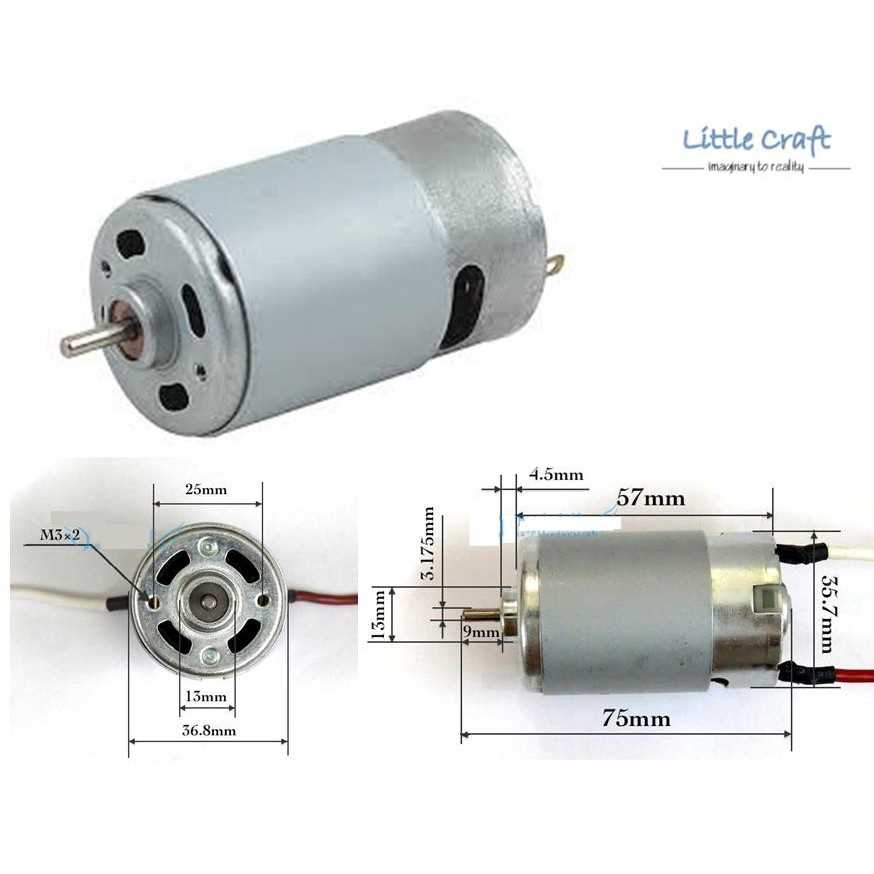

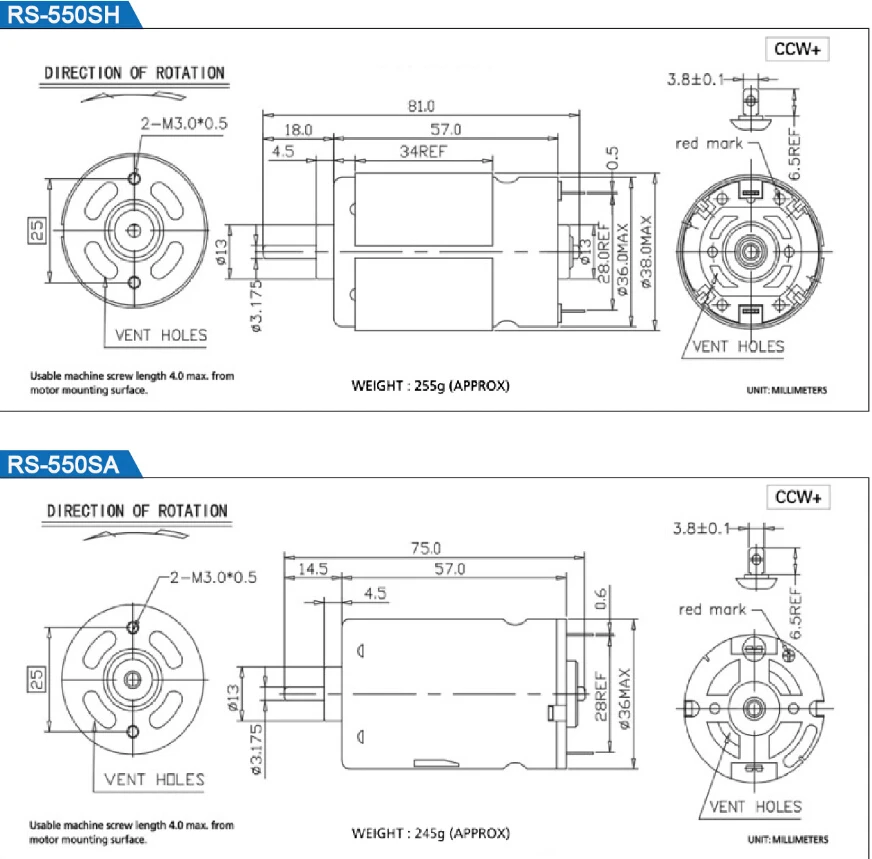

Physical Dimensions and Construction

Going beyond abstract metrics, the physical dimensions and construction of a DC 12-volt motor furnish crucial insights into its practical applicability. From compact designs suited for constrained spaces to robust constructions engineered for heavy-duty tasks, these aspects define the motor’s adaptability to specific environments and operational demands.

Exploring Essential Parameters in Motor Specifications

In the realm of electrical machinery, comprehending the intricate details outlined in motor documentation is paramount. By delving into the nuances of these specifications, one can unravel the performance characteristics and operational intricacies that define the essence of a motor.

Let’s embark on a journey through the labyrinth of motor data, dissecting crucial parameters that underpin its functionality and efficiency. From torque to efficiency ratings, each datum serves as a mosaic piece, contributing to the holistic understanding of motor behavior.

- Power Consumption: This metric elucidates the electrical input required to propel the motor into action, dictating its energy efficiency and operational costs.

- Torque: The rotational force exerted by the motor, a pivotal parameter influencing its ability to drive mechanical loads with precision and vigor.

- Speed: A fundamental characteristic delineating the velocity at which the motor’s shaft rotates, directly impacting its performance across diverse applications.

- Operating Temperature: A critical aspect indicative of the thermal boundaries within which the motor can operate optimally, safeguarding against overheating and potential damage.

- Dimensions: The physical footprint of the motor, encompassing its size, weight, and form factor, pivotal considerations in design and integration endeavors.

Each parameter interlaces with the others, forming a cohesive narrative that illuminates the motor’s capabilities and limitations. By discerning these intricacies, engineers and enthusiasts alike can harness the full potential of these electromechanical marvels.

Interpreting Efficiency Metrics of 12V Direct Current Motor

Understanding the operational efficiency of a 12V DC motor entails deciphering various performance indicators provided within its documentation. This section delves into the metrics and terminology associated with evaluating the effectiveness of the motor’s energy utilization.

Efficiency Ratio Analysis

Efficiency ratio serves as a pivotal gauge for assessing the competency of a motor in converting electrical energy into mechanical output. By scrutinizing this metric, one can discern the extent to which the motor optimizes its energy resources.

- Power Conversion Efficiency: This parameter indicates the proportion of input power that the motor successfully converts into useful mechanical work. It elucidates the motor’s ability to minimize energy loss during operation.

- Load Efficiency: Load efficiency refers to the motor’s performance under varying workload conditions. Analyzing this metric elucidates how effectively the motor sustains its efficiency across different operational demands.

- Overall Efficiency: Combining various factors such as frictional losses, heat dissipation, and electrical resistance, overall efficiency encapsulates the motor’s comprehensive performance. It provides a holistic view of the motor’s energy conversion proficiency.

Interpretation Guidelines

Deciphering the efficiency data necessitates a nuanced understanding of the motor’s operational context and the significance of each metric in real-world applications. Here are some guidelines to facilitate the interpretation process:

- Contextual Analysis: Consider the intended application and environmental factors influencing motor performance. Evaluate efficiency metrics in alignment with the specific requirements of the application.

- Comparative Assessment: Compare efficiency data with industry standards and benchmarks to ascertain the motor’s competitiveness and potential areas for improvement.

- Long-term Performance: Look beyond instantaneous efficiency values and assess the motor’s sustainability in maintaining optimal performance over its operational lifespan.

By applying these interpretive strategies, stakeholders can derive actionable insights from the efficiency data to inform decision-making processes and enhance the overall efficiency of motor-driven systems.

Maximizing Performance and Energy Conservation

In the pursuit of optimizing system functionality and minimizing power consumption, strategic measures can be employed to enhance overall performance while conserving energy resources. This section delves into effective techniques and considerations aimed at achieving both objectives synergistically.

Efficiency Enhancement Strategies

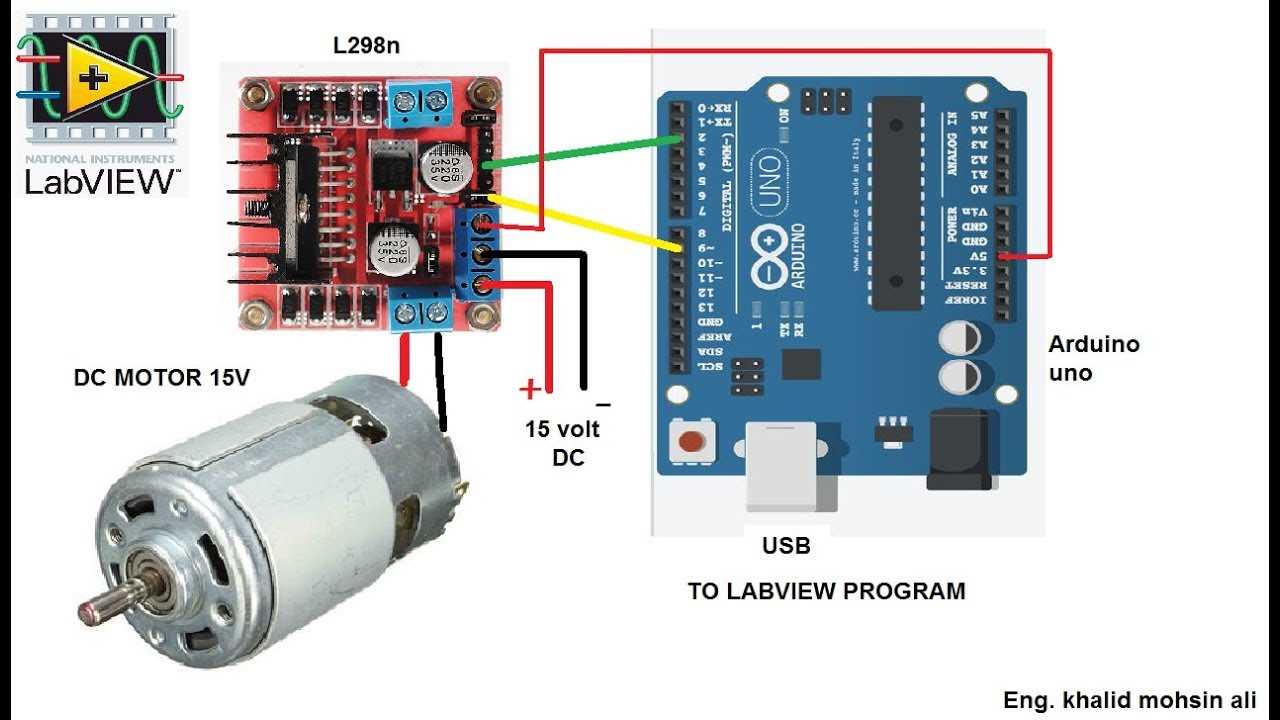

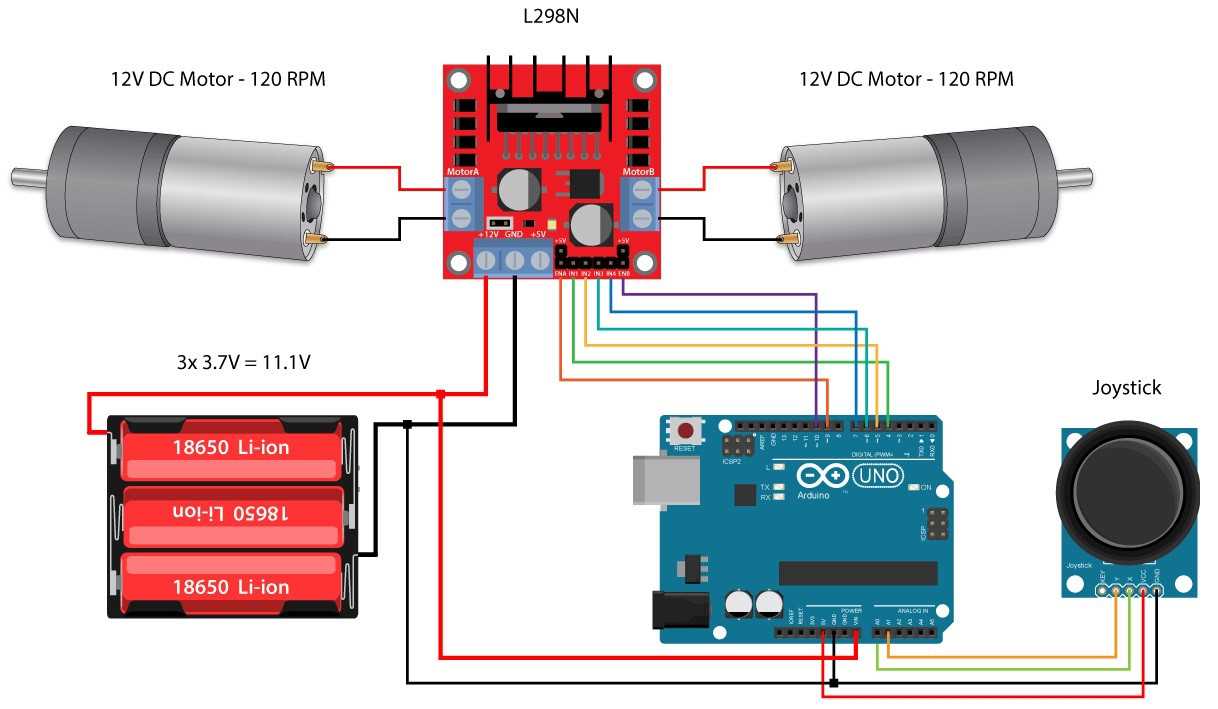

- Implementing advanced control algorithms to streamline operational processes.

- Utilizing high-quality components to mitigate energy losses and enhance system reliability.

- Employing intelligent feedback mechanisms for real-time adjustment and optimization.

Energy Conservation Practices

- Adopting power management protocols to minimize standby power consumption.

- Exploring regenerative braking techniques to recover and reuse kinetic energy.

- Integrating sleep modes and idle state optimizations for periods of inactivity.

By integrating these strategies into the design and operation of motor-driven systems, significant advancements in performance and energy efficiency can be realized, paving the way for sustainable and resource-conscious engineering practices.

Deciphering DC 12 Volt Motor Torque Curves

In this section, we delve into the intricate patterns and dynamics encapsulated within the torque curves of DC 12-volt motors. Understanding these curves is pivotal for comprehending the nuanced performance characteristics and operational capabilities of these electric propulsion systems.

Initially, we explore the fundamental principles underlying torque curves, elucidating the relationship between rotational force and speed in the context of DC 12-volt motors. Subsequently, we analyze the intricate interplay between torque, current, and voltage, unraveling the mechanisms that govern motor performance across varying operating conditions.

Furthermore, we examine the implications of torque curves on practical applications, elucidating how torque characteristics influence the efficiency, responsiveness, and overall functionality of devices powered by DC 12-volt motors. Through meticulous analysis and interpretation, we aim to empower engineers and enthusiasts alike to harness the full potential of these electric propulsion systems.