Unlocking the intricacies of a dynamic mechanical ensemble catalog, this documentation delves into the heart of innovation, offering a comprehensive glimpse into the framework of motion-generation technology.

Embark on a journey through the blueprint of propulsion, where each component is meticulously outlined to elucidate its role in orchestrating fluid dynamics.

Explore the nuanced descriptors, unraveling the essence of performance metrics and design paradigms, guiding aspirants through a labyrinth of technical mastery.

Understanding Technical Specifications for Mixing Equipment

In the realm of industrial equipment documentation, navigating through technical specifications can often feel like deciphering a complex code. When it comes to comprehending the intricacies of machinery like mixers and stirrers, having a grasp of the information presented in datasheets is paramount. These documents serve as a compass, guiding engineers and operators through the labyrinth of features, capabilities, and performance metrics of these dynamic devices.

Deciphering Performance Metrics

At the heart of any agitator datasheet lies a wealth of performance metrics that provide insight into the capabilities and limitations of the equipment. Understanding the nuances of terms such as torque, power consumption, and rotational speed is crucial for selecting the right agitator for a specific application. By dissecting these metrics, one can glean valuable information about the efficiency, reliability, and suitability of the agitating equipment for a given task.

Interpreting Operational Parameters

Beyond performance metrics, agitator datasheets also encapsulate a spectrum of operational parameters essential for seamless integration into industrial processes. Parameters like vessel size compatibility, mounting options, and material compatibility shed light on the practical aspects of deploying agitating equipment in diverse environments. Mastery of these operational parameters ensures optimal utilization of agitators, minimizing downtime and maximizing productivity.

| Key Metric | Description |

|---|---|

| Torque | The rotational force exerted by the agitator shaft, crucial for mixing viscous substances. |

| Power Consumption | The electrical power required to drive the agitator, indicative of its energy efficiency. |

| Rotational Speed | The speed at which the agitator shaft rotates, influencing mixing intensity and homogeneity. |

By unraveling the mysteries hidden within agitator datasheets, engineers and operators can make informed decisions, ensuring seamless integration and optimal performance of mixing equipment in diverse industrial settings.

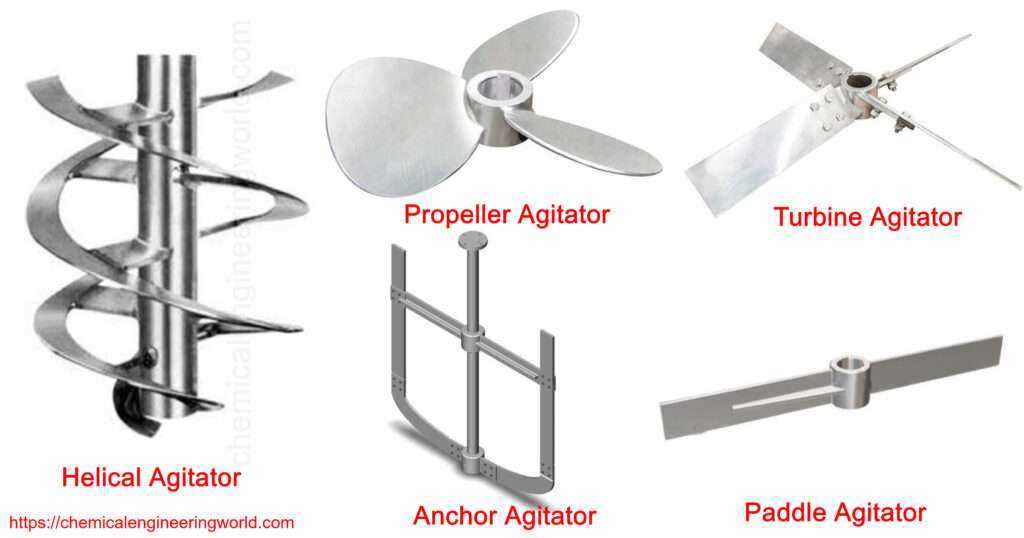

Key Components Demystified

In this section, we delve into the essential elements that comprise the backbone of the agitation system. Understanding these pivotal components is crucial for grasping the intricacies of the machinery’s operation and optimizing its performance.

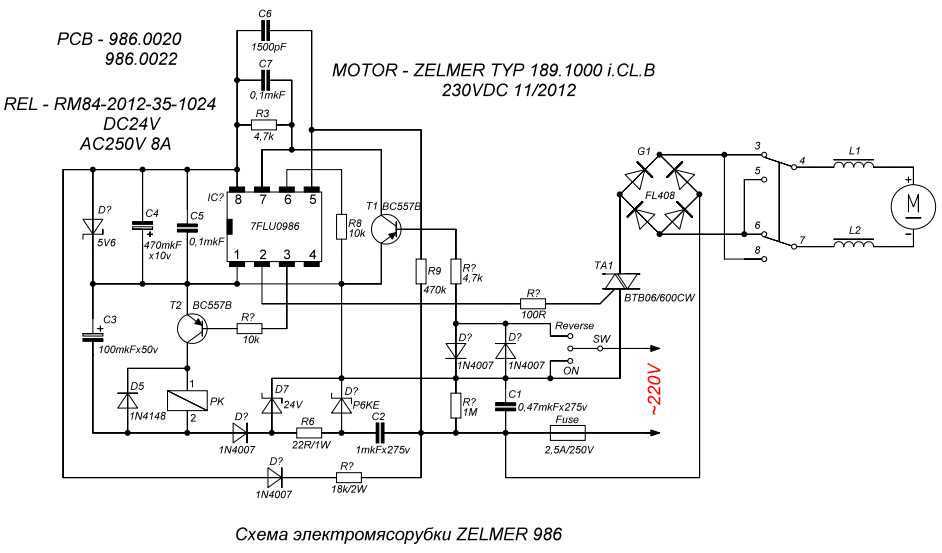

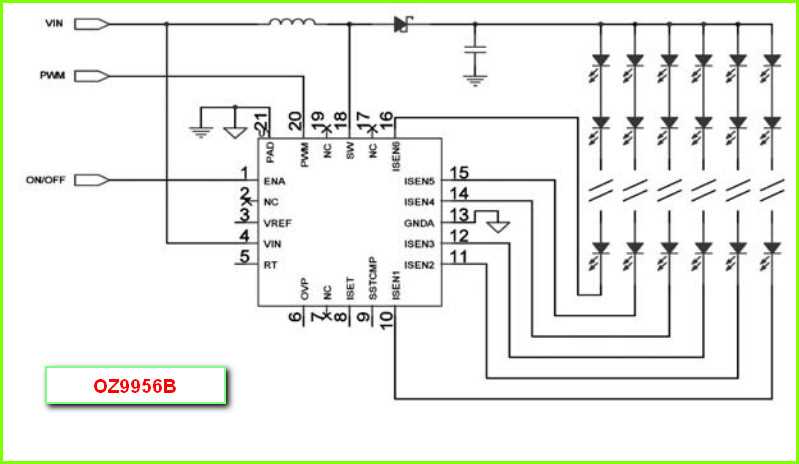

- Drive Mechanism: The powerhouse behind the movement, the drive mechanism imparts motion to the system, facilitating the stirring action. It encompasses various mechanisms, each tailored to suit specific agitation needs.

- Impeller: Serving as the propeller of the agitation process, the impeller plays a pivotal role in generating fluid motion. Its design, size, and shape greatly influence the efficiency and characteristics of agitation.

- Shaft Assembly: Acting as the conduit between the drive mechanism and the impeller, the shaft assembly transmits power while maintaining stability and alignment. Its construction and material composition are paramount for ensuring durability and reliability.

- Bearing System: Providing support and reducing friction, the bearing system is integral for smooth operation. The selection of bearings, their configuration, and maintenance significantly impact the longevity and performance of the agitation system.

- Sealing Arrangement: Preventing leakage and contamination, the sealing arrangement ensures the integrity of the system. Its design and effectiveness are crucial for safeguarding both the equipment and the environment.

By demystifying these key components, users can gain deeper insights into the inner workings of the agitation system, empowering them to make informed decisions regarding maintenance, troubleshooting, and optimization.

Interpreting Performance Metrics

Understanding the significance of performance measurements is pivotal in comprehending the effectiveness and efficiency of a given system. Metrics serve as indicators, shedding light on the operational prowess and potential areas of improvement within a mechanism or process.

The Essence of Performance Metrics

Performance metrics, often referred to as performance indicators or gauges, encapsulate quantitative and qualitative assessments of a system’s functionality. These metrics encompass a spectrum of parameters, spanning from throughput and efficiency to reliability and quality.

Deciphering Metric Insights

Interpreting performance metrics involves more than just scrutinizing numerical values; it requires contextual comprehension and insightful analysis. Metrics unveil patterns, trends, and anomalies, offering valuable insights into the intricacies of system behavior.

Optimizing Agitation for Enhanced Performance

Effective stirring is vital for achieving optimal outcomes in various industrial processes. This section delves into strategies aimed at maximizing the efficiency of agitation systems, thereby improving overall productivity and quality of operations.

The Role of Proper Mixing

Efficient mixing plays a pivotal role in ensuring uniform distribution of substances, facilitating chemical reactions, and enhancing mass transfer rates. By strategically manipulating the flow patterns within the vessel, operators can expedite processes while minimizing energy consumption.

Factors Influencing Agitation Efficiency

Several factors influence the effectiveness of agitation systems, including fluid viscosity, vessel geometry, impeller design, and rotational speed. Understanding the interplay of these variables empowers operators to tailor agitation parameters to specific requirements, optimizing performance and resource utilization.

Employing advanced computational fluid dynamics (CFD) simulations and empirical testing methodologies enables precise characterization of agitation dynamics, facilitating informed decision-making and continual improvement initiatives.