Diving into the realm of microelectronics unveils a labyrinth of intricacies, where every component plays a pivotal role in the grand symphony of functionality.

Embedded within the fabric of modern technology lies a tiny yet mighty entity, a cornerstone of circuitry prowess that orchestrates data storage and retrieval with finesse.

As we embark on this journey of discovery, we navigate through the lexicon of electronic engineering, delving into the intricate details of a vital cog in the machinery of innovation.

The Fundamentals of Understanding Technical Documentation for 24c04 Devices

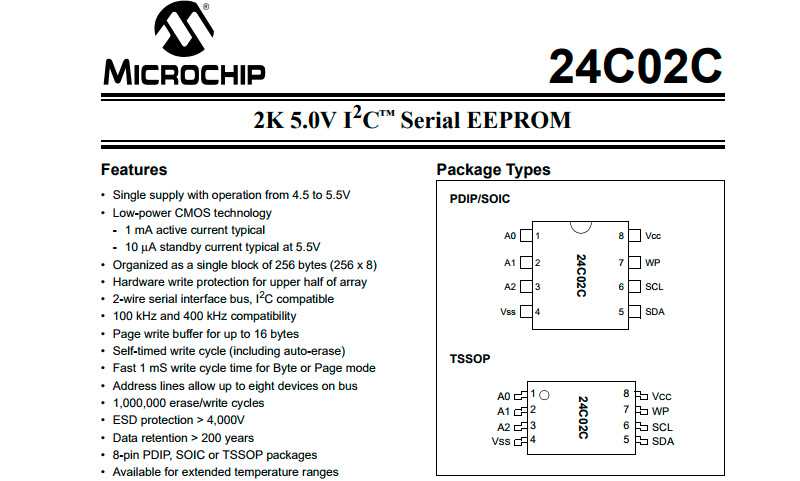

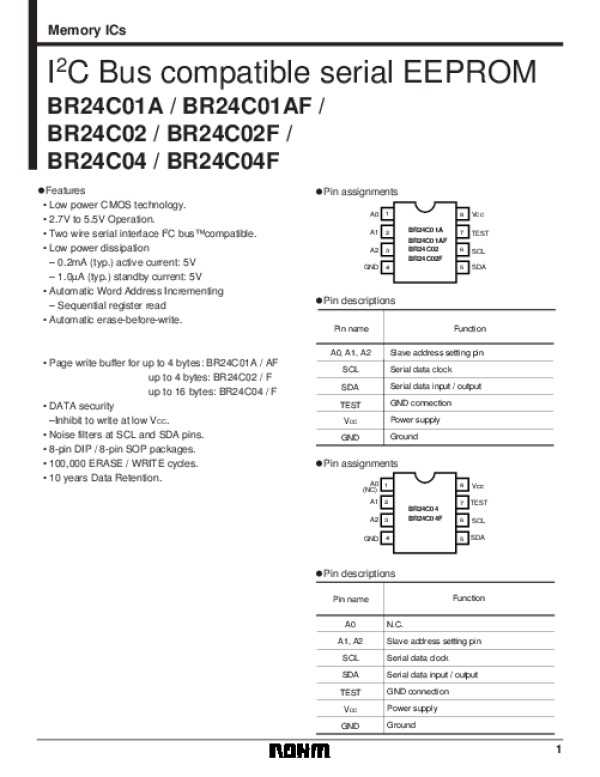

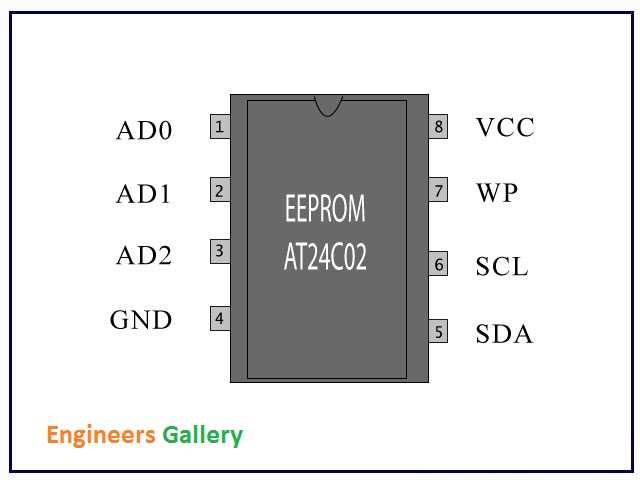

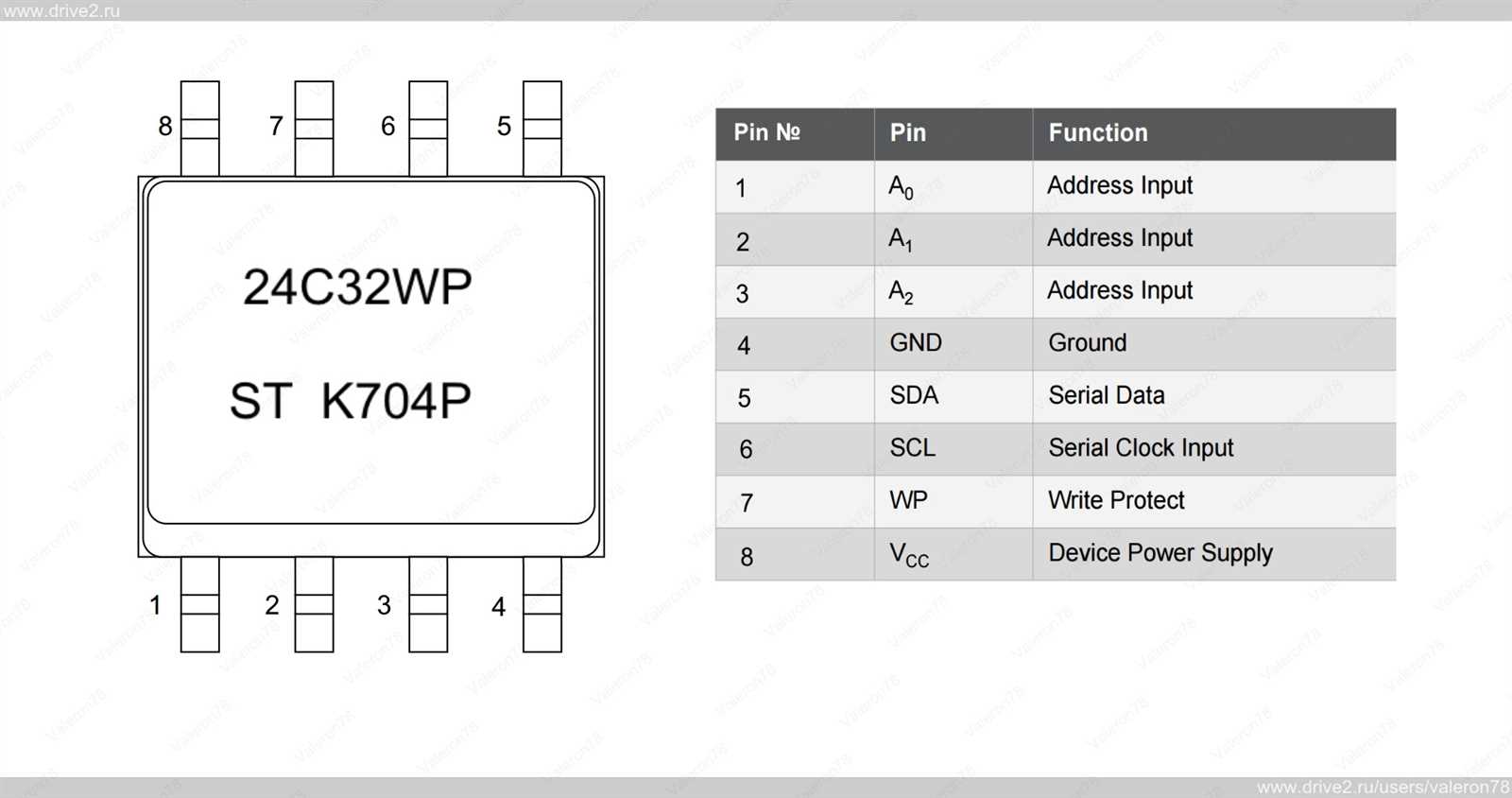

Exploring the intricacies of modern electronic components requires a comprehensive grasp of the technical documentation associated with these devices. In this section, we delve into the fundamental aspects of deciphering the specifications and guidelines provided in the documentation for 24c04-type integrated circuits.

Understanding Component Specifications

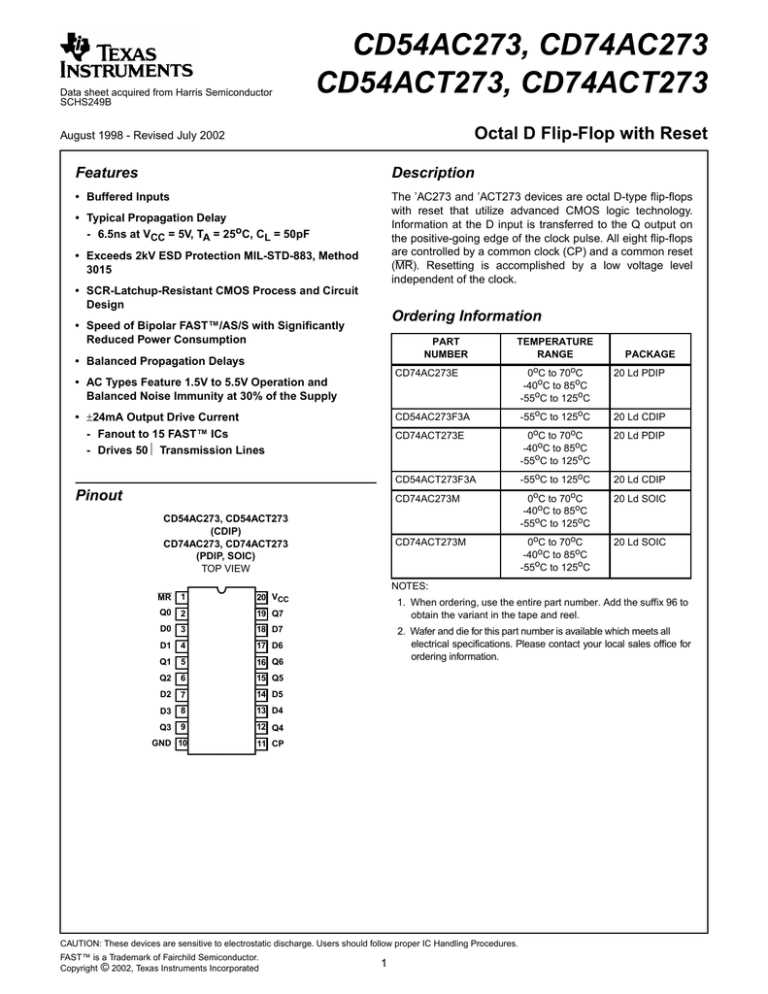

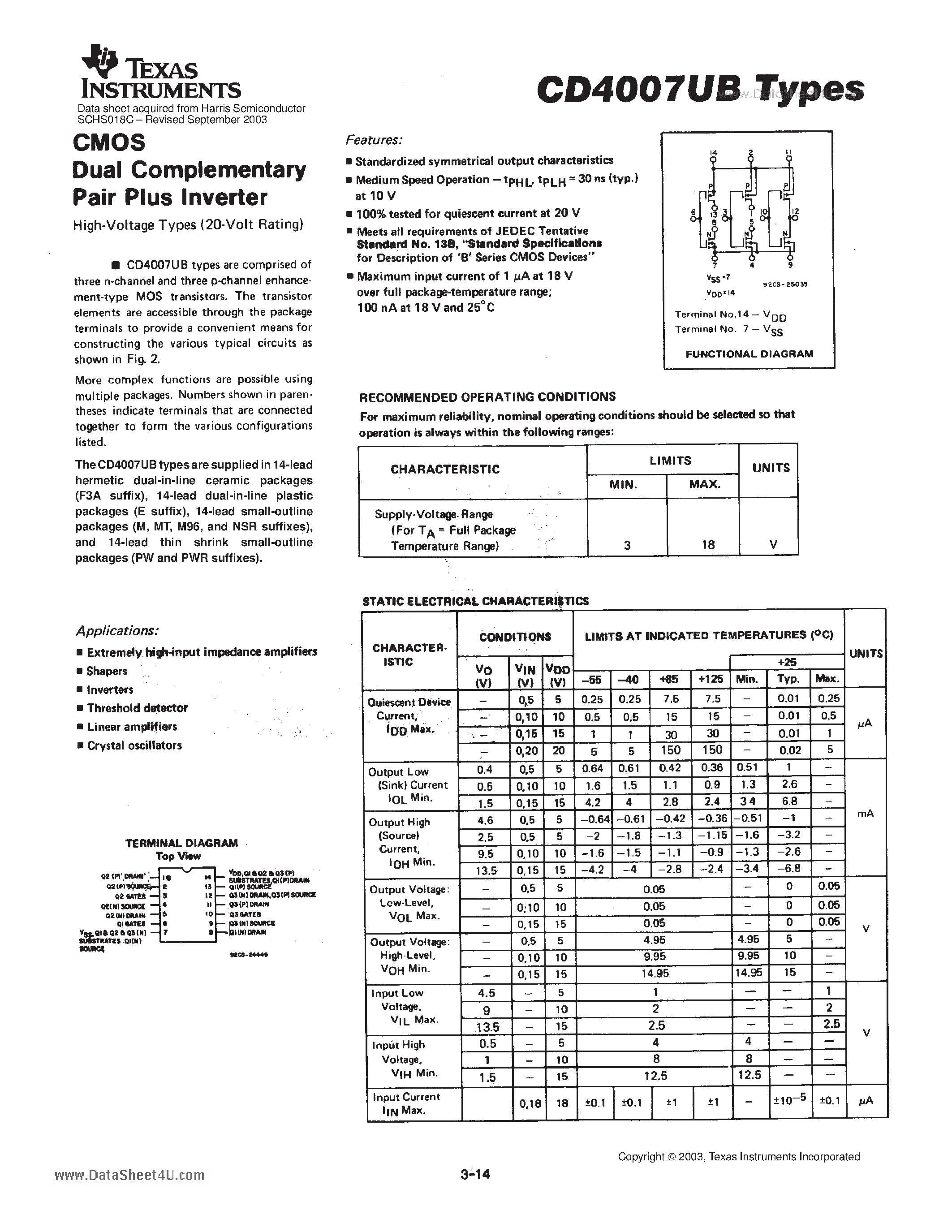

When delving into the realm of electronic components, understanding the specifications provided is paramount. These specifications serve as a roadmap, detailing the operational parameters, performance characteristics, and electrical requirements of the component in question. Within the context of 24c04 devices, comprehending these specifications elucidates crucial details about the device’s capabilities and limitations.

Navigating Operational Guidelines

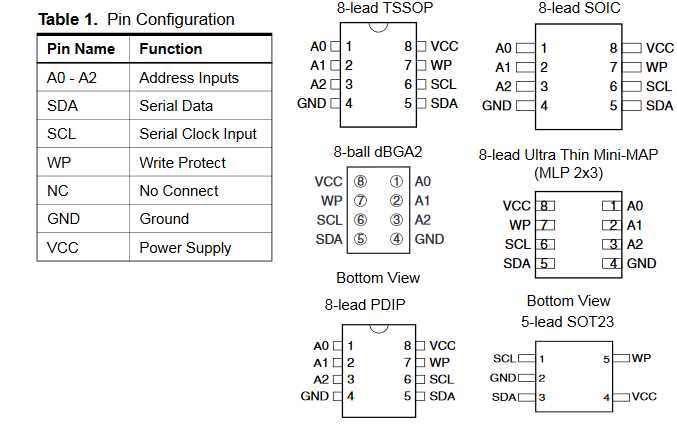

Beyond mere specifications, the documentation also furnishes operational guidelines essential for integrating the component into a larger system effectively. These guidelines encompass aspects such as recommended operating conditions, timing diagrams, and data transfer protocols. Mastery of these operational guidelines ensures optimal performance and reliability of the 24c04 device within its intended application.

By acquainting oneself with the fundamental principles outlined in the technical documentation, one can navigate the intricacies of 24c04 devices with confidence and precision, unlocking their full potential in various electronic designs.

Understanding the Essential Specifications

In delving into the intricacies of this component’s technical dossier, it is imperative to grasp the core specifications that delineate its performance parameters. Here, we embark on a journey to unravel the fundamental characteristics that define its functionality and operational nuances.

1. Performance Metrics

At the heart of comprehending the essence of this component lies an exploration into its performance metrics. These metrics encapsulate a myriad of facets, including speed, endurance, and efficiency, which collectively underpin its efficacy in diverse applications.

2. Functional Capabilities

Beyond mere numerical values, the functional capabilities elucidate the component’s aptitude to fulfill specific tasks within a given system architecture. Understanding these capabilities entails discerning its compatibility, reliability, and versatility in varying operational scenarios.

Applications and Implementations of EEPROM Memory

In this section, we explore the diverse array of applications and practical implementations of the EEPROM memory addressed in the 24c04 datasheet. This versatile form of non-volatile memory finds utility across various industries and technological domains.

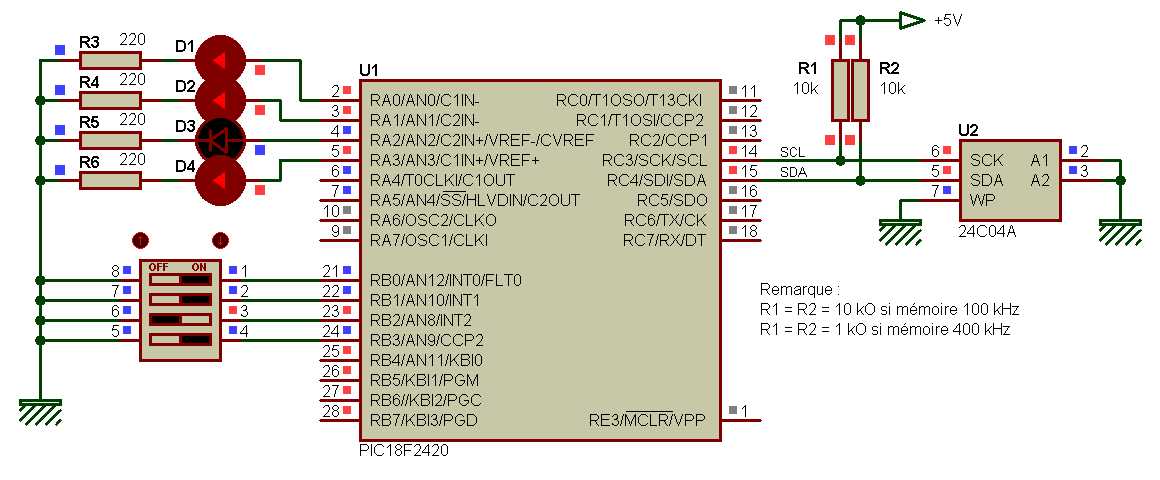

- Embedded Systems: EEPROM memory serves as a crucial component in embedded systems, facilitating data storage and retrieval for microcontrollers and other embedded devices. Its ability to retain data without power makes it ideal for storing configuration settings, calibration data, and other essential parameters.

- Consumer Electronics: From smart appliances to handheld devices, EEPROM memory plays a pivotal role in enhancing user experience. It enables features like personalized settings, firmware upgrades, and event logging, ensuring seamless operation and adaptability in consumer electronics products.

- Automotive Industry: In automotive applications, EEPROM memory contributes to vital functions such as engine management, vehicle diagnostics, and infotainment systems. It stores critical data such as error codes, sensor calibrations, and user preferences, enabling efficient vehicle operation and maintenance.

- Industrial Automation: The reliability and durability of EEPROM memory make it indispensable in industrial automation settings. It facilitates configuration storage for programmable logic controllers (PLCs), data logging in supervisory control and data acquisition (SCADA) systems, and parameter storage in machinery and equipment.

- Medical Devices: In medical devices and equipment, EEPROM memory ensures the integrity and security of patient data, device settings, and calibration parameters. It enables traceability, compliance with regulatory standards, and customization based on individual patient needs.

Overall, the widespread adoption of EEPROM memory, as detailed in the 24c04 datasheet, underscores its significance in modern technology ecosystems. Its versatility, reliability, and endurance make it indispensable across a multitude of applications, driving innovation and efficiency in diverse industries.

Exploring Real-world Scenarios

In this section, we delve into practical applications and real-life instances where electronic components similar to the 24c04 EEPROM chip play pivotal roles. From industrial automation to consumer electronics, these components serve as the backbone of various systems, enabling functionalities ranging from data storage to system configuration.

Industrial Automation: Within manufacturing plants and industrial facilities, EEPROM chips, akin to the 24c04, are employed for storing critical parameters and calibration data. These chips ensure seamless operation of machinery, facilitating precise control and monitoring of processes.

Consumer Electronics: In the realm of consumer electronics, EEPROM chips find their utility in devices such as smart TVs, digital cameras, and home appliances. They store user preferences, configuration settings, and firmware updates, enhancing the overall user experience and customization options.

Automotive Systems: Modern automobiles integrate EEPROM chips for storing vehicle-specific data, including engine parameters, diagnostic information, and multimedia preferences. These components contribute to vehicle performance optimization and facilitate the implementation of advanced features such as driver assistance systems.

Medical Devices: In medical equipment and devices, EEPROM chips are utilized for storing patient data, device configurations, and firmware updates. These components ensure data integrity, compliance with regulatory standards, and seamless integration with healthcare information systems.

Security Systems: Within security systems and access control solutions, EEPROM chips play a crucial role in storing authentication credentials, access logs, and encryption keys. These components are essential for maintaining the integrity and confidentiality of sensitive information, safeguarding both physical and digital assets.

Embedded Systems: In the realm of embedded systems and IoT (Internet of Things) devices, EEPROM chips serve as non-volatile memory solutions for storing device configurations, sensor data, and communication protocols. These components enable efficient operation, data persistence, and remote management capabilities.

Through exploring these diverse real-world scenarios, we gain a deeper understanding of the versatility and significance of EEPROM chips, exemplified by the functionalities akin to the 24c04, across various domains and industries.

Troubleshooting and Optimal Approaches for Utilizing Technical Documentation

When navigating through technical resources for integrated circuits, it’s imperative to equip oneself with troubleshooting skills and adhere to best practices. This section delves into strategies for effectively utilizing and interpreting documentation pertinent to the specific IC model, fostering a smoother integration process and minimizing potential setbacks.

Understanding Circuit Behavior: Before delving into the intricacies of troubleshooting, it’s crucial to develop a comprehensive understanding of the expected behavior of the integrated circuit. Familiarize yourself with the operational principles and functionalities to discern between normal and anomalous operation.

Interpreting Signal Waveforms: Signal waveforms serve as invaluable indicators of circuit performance. Employ oscilloscopes or logic analyzers to meticulously scrutinize waveforms, identifying irregularities that could indicate underlying issues.

Comprehending Timing Diagrams: Timing diagrams encapsulate the temporal relationships between various signals within the circuit. Devote adequate time to deciphering these diagrams, as they elucidate crucial details regarding data transmission, clock synchronization, and protocol adherence.

Addressing Common Pitfalls: Anticipate and preemptively mitigate common pitfalls encountered during integration. From bus contention to address conflicts, preemptive measures such as proper pull-up resistor placement and meticulous address assignment can circumvent potential complications.

Utilizing Supplementary Resources: In addition to the datasheet, leverage supplementary resources such as application notes and reference designs provided by the manufacturer. These resources offer invaluable insights, elucidating nuanced aspects of circuit operation and offering practical implementation guidelines.

Collaborative Troubleshooting: Embrace collaborative troubleshooting methodologies, tapping into online forums, discussion groups, and technical communities. Pooling collective expertise can expedite issue resolution and offer alternative perspectives on intricate challenges.

Iterative Testing and Validation: Adopt an iterative approach to testing and validation, systematically verifying each component of the circuit against expected benchmarks. Through meticulous iteration and validation cycles, gradually refine the implementation until optimal performance is achieved.

Documentation Revision and Update: Acknowledge the dynamic nature of technical documentation and prioritize periodic revision and update. Stay abreast of errata sheets, firmware updates, and revised datasheets to align with the latest specifications and rectify any discrepancies.

By assimilating these troubleshooting methodologies and adhering to best practices, engineers can navigate through the intricacies of technical documentation with confidence, fostering seamless integration and optimal performance of the integrated circuit.