Exploring the intricate blueprint of motor control systems entails delving into a realm where precision and performance converge. Within the labyrinth of technical documentation lies a roadmap, a guide to harnessing the potential of motor drivers. Embedded within these documents are the keys to understanding the core principles that propel machinery into motion.

Unlocking the potential of motor drivers necessitates a meticulous examination of their specifications, akin to deciphering a cryptic code. These documents serve as treasure troves of information, revealing the intricacies of voltage requirements, current thresholds, and operational limits. By unraveling these details, engineers embark on a journey towards optimizing motor performance and efficiency.

Within the confines of these technical blueprints lie the building blocks of innovation, providing engineers with the raw materials to sculpt their designs. Each specification, each parameter, is a brushstroke on the canvas of engineering creativity, shaping the landscape of motor-driven technologies.

Understanding DRV8811 Documentation: Essential Features and Specifications

In the realm of motor control electronics, comprehending the intricacies of technical documentation is paramount for engineers and enthusiasts alike. Delving into the DRV8811 documentation unveils a treasure trove of essential features and specifications, pivotal for harnessing the full potential of this motor driver.

Key Features

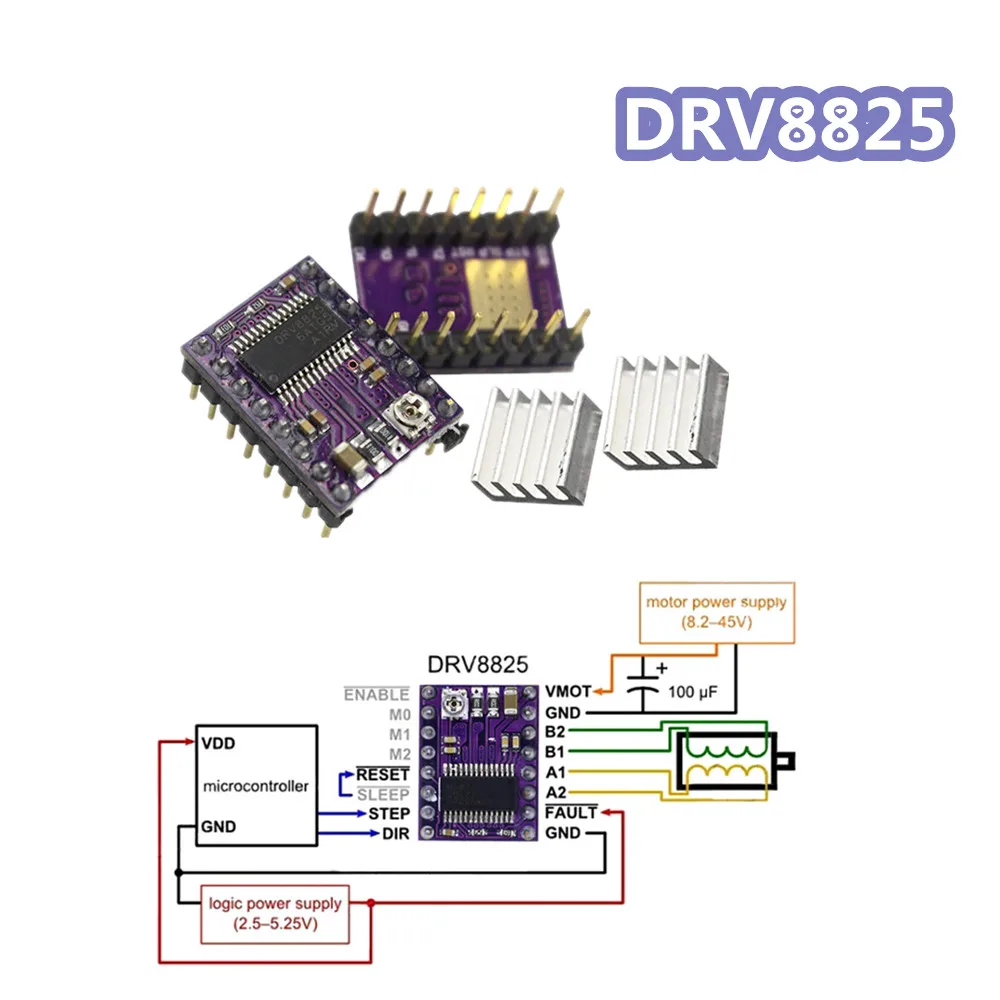

- Performance Metrics: Explore the performance metrics indicative of the DRV8811’s capabilities, ranging from voltage and current ratings to protection mechanisms.

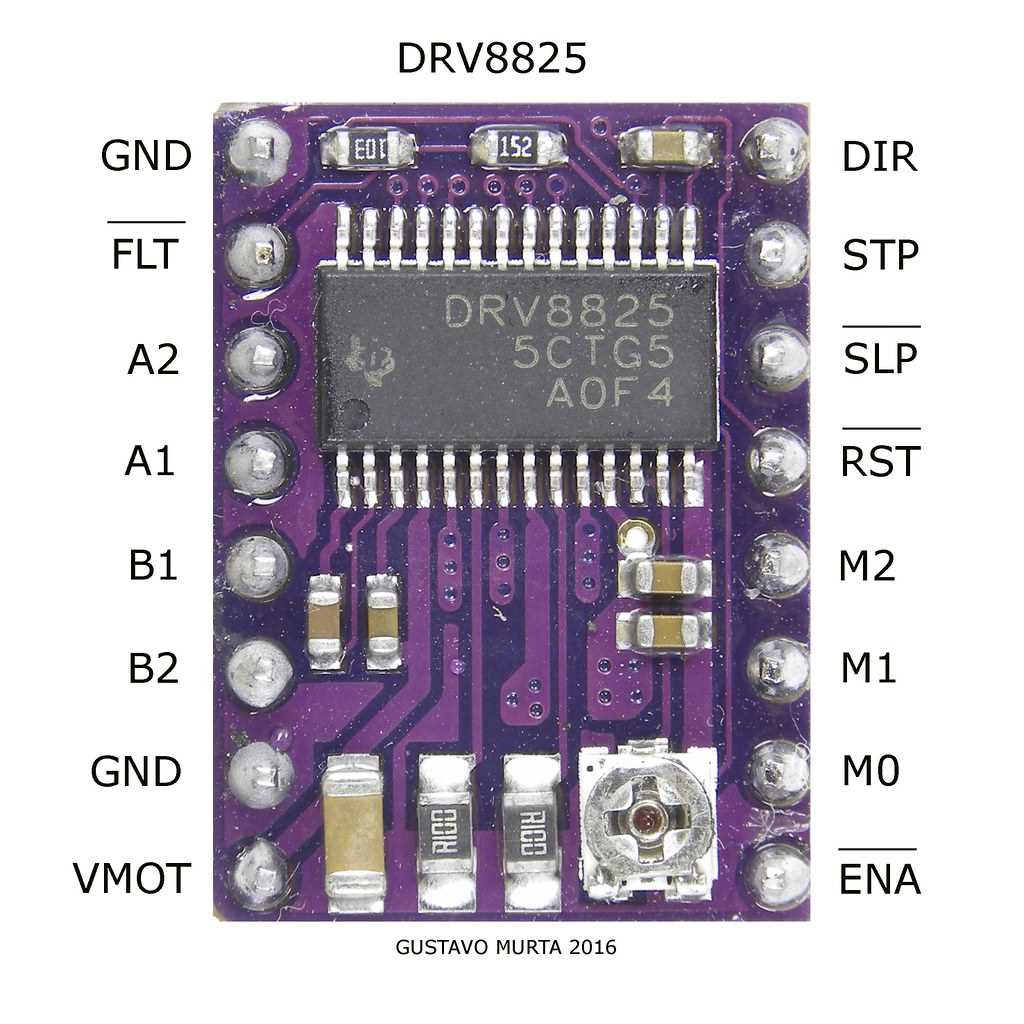

- Control Options: Uncover the diverse control options available, from PWM control to microstepping, enabling precise motor manipulation.

- Diagnostic Features: Examine the diagnostic features embedded within the DRV8811, facilitating troubleshooting and enhancing system reliability.

Specifications Overview

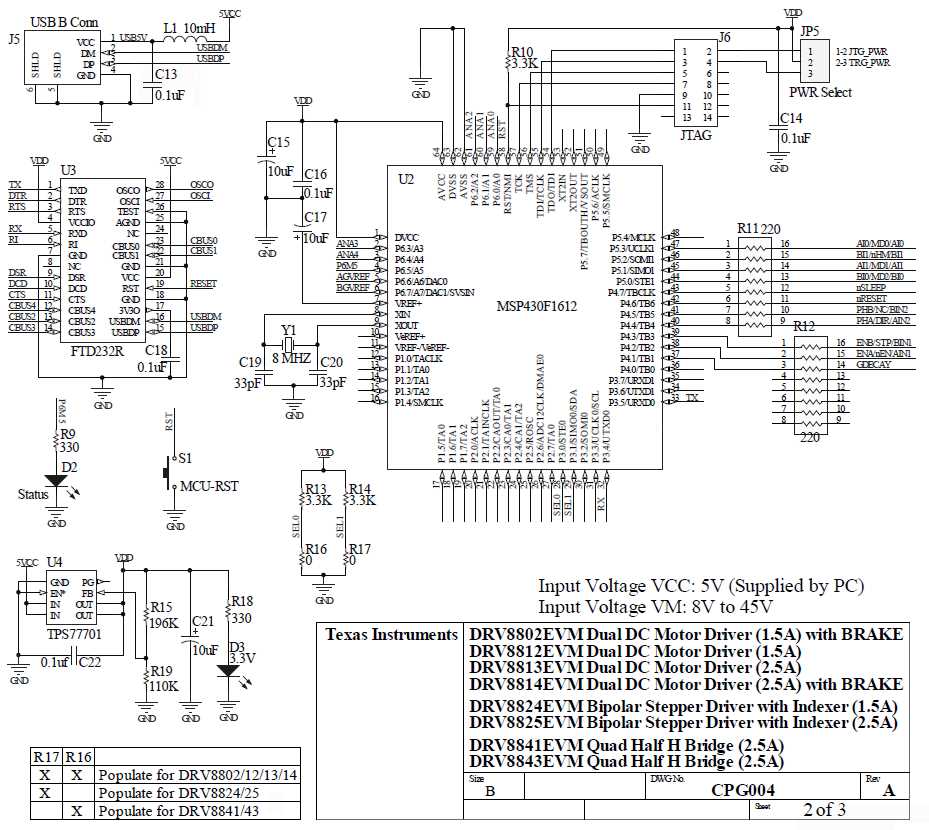

- Electrical Specifications: Navigate through the electrical specifications, encompassing voltage ranges, current limits, and power dissipation characteristics.

- Mechanical Dimensions: Gain insight into the mechanical dimensions of the DRV8811, crucial for seamless integration into various applications.

- Environmental Considerations: Evaluate environmental factors such as operating temperature ranges and thermal resistance to ensure optimal performance across diverse operating conditions.

By comprehensively understanding the features and specifications delineated in the DRV8811 documentation, one can harness its full potential in motor control applications, paving the way for innovation and efficiency.

Exploring the Technical Specifications

In this section, we delve into the intricacies and nuances of the technical specifications of the DRV8811, unraveling its capabilities and functionalities. Through a detailed examination of its parameters and performance metrics, we aim to provide a comprehensive understanding of its operational characteristics and potential applications.

Functional Parameters

Within the realm of technical specifications lie a plethora of functional parameters that define the behavior and operation of the DRV8811. These parameters encompass aspects such as voltage ratings, current limits, and control interfaces, each playing a pivotal role in shaping the device’s performance.

Performance Metrics

Beyond the realm of functionality, the DRV8811’s performance metrics offer valuable insights into its efficiency, reliability, and overall effectiveness in diverse usage scenarios. From efficiency ratings to thermal characteristics, these metrics provide a holistic view of the device’s capabilities and limitations.

Key Features and Advantages for Motor Control Applications

In this section, we explore the fundamental attributes and benefits tailored specifically for optimizing motor control in various applications. Delve into the intricacies of this technological marvel, uncovering its prowess in enhancing operational efficiency and performance.

1. Precision Control: Harnessing advanced mechanisms, this technology ensures meticulous regulation of motor functions, facilitating seamless operation and precise maneuverability.

2. Enhanced Efficiency: Through innovative design elements, it maximizes energy utilization, promoting sustainable practices and minimizing operational costs.

3. Versatile Adaptability: Adaptable to diverse motor control requirements, it offers flexibility in application, catering to a spectrum of industrial and automotive needs with ease.

4. Robust Reliability: Engineered with durability in mind, it guarantees steadfast performance even under demanding conditions, ensuring uninterrupted functionality and longevity.

5. Streamlined Integration: Seamlessly integrate this technology into existing systems, optimizing workflow efficiency and simplifying implementation processes.

6. Safety Assurance: Prioritizing safety standards, it incorporates protective features to mitigate risks, safeguarding both equipment and personnel from potential hazards.

7. Future-Proof Design: Continuously evolving to meet evolving industry demands, it boasts a future-proof design, offering scalability and adaptability for forthcoming technological advancements.

Unveil the transformative potential of this innovative solution as it revolutionizes motor control landscapes, empowering industries with unparalleled efficiency and performance.

Exploring Applications and Implementation Tips for the DRV8811

In this section, we delve into practical scenarios and insightful strategies for effectively utilizing and integrating the DRV8811 motor driver. Through diverse application examples and nuanced implementation tips, we aim to provide comprehensive guidance for harnessing the full potential of this versatile component.

1. Application Examples

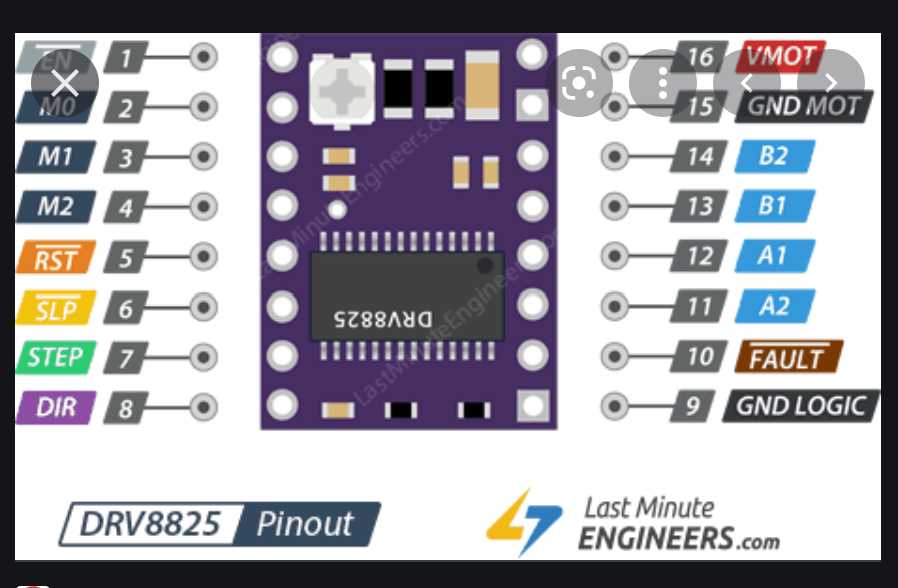

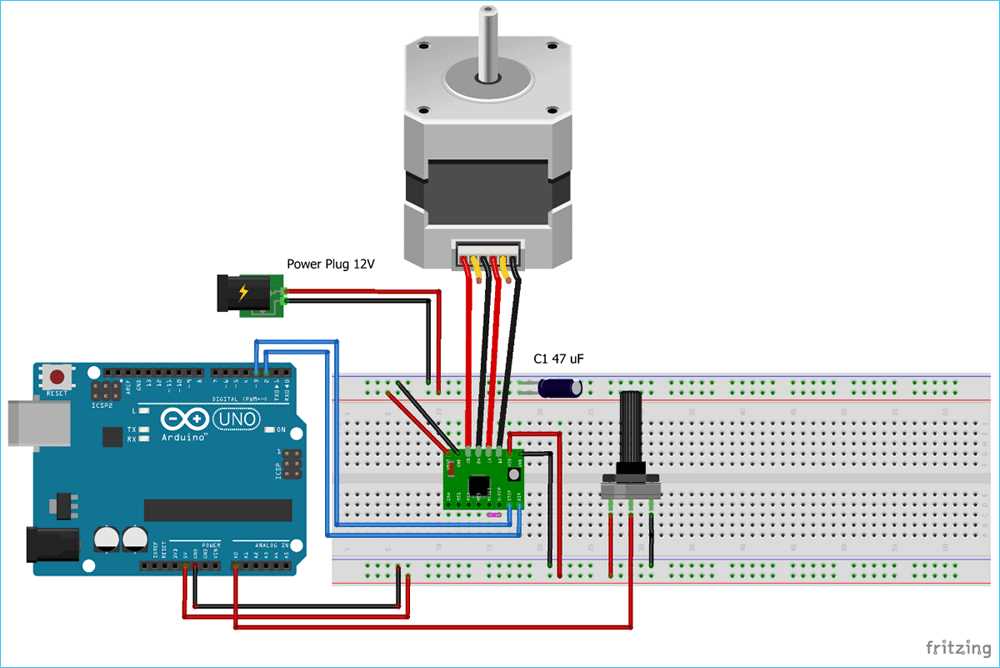

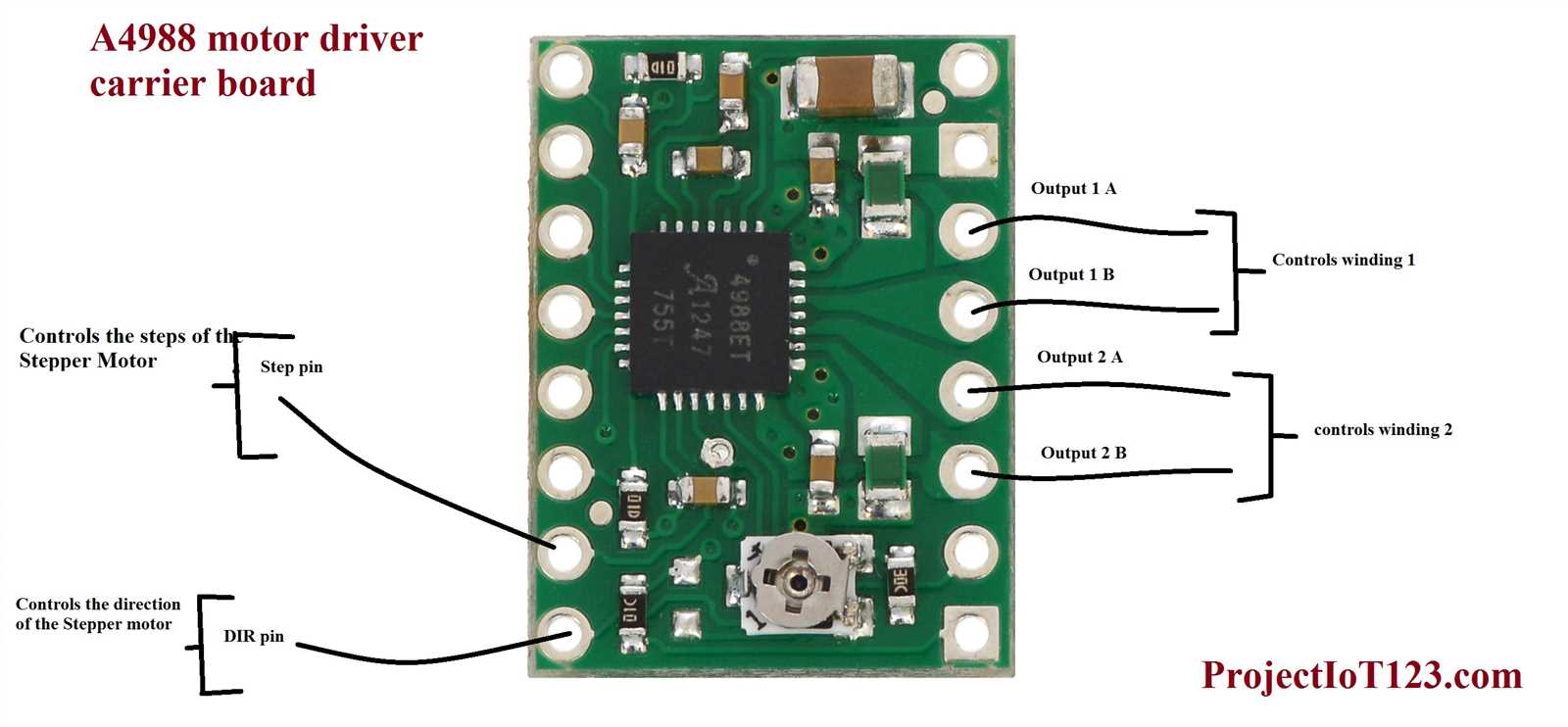

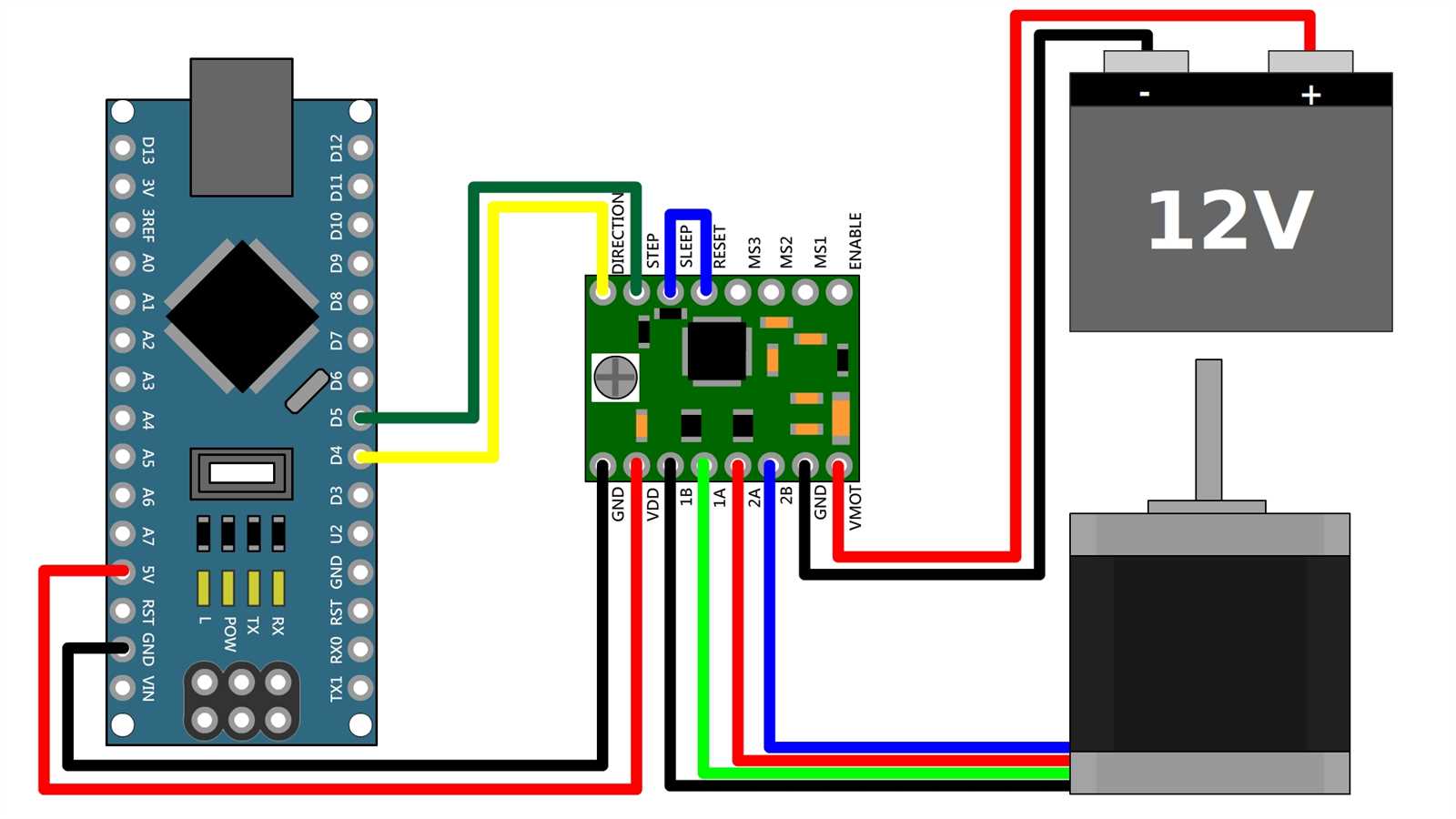

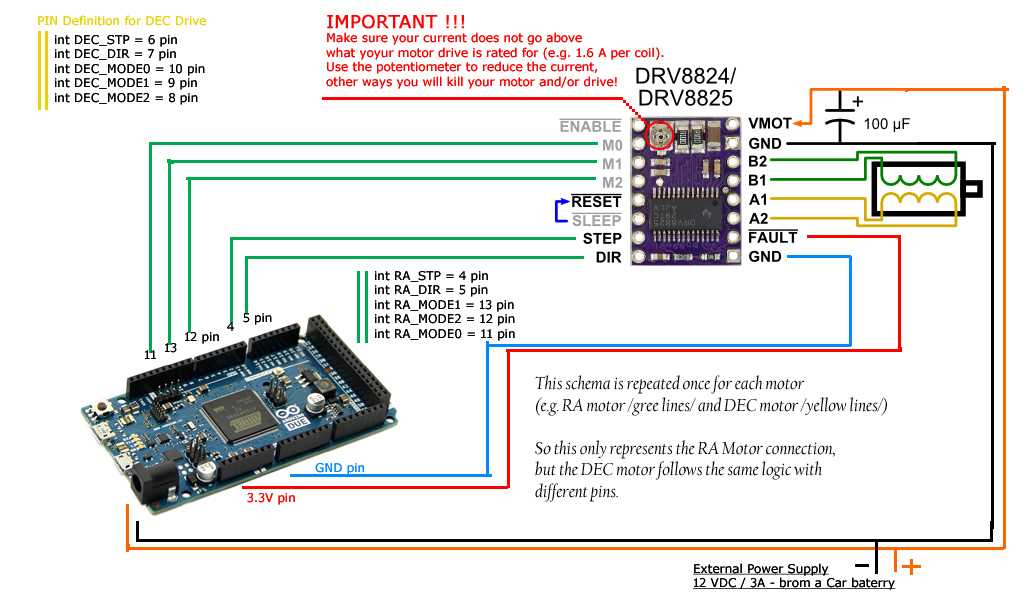

- Driving Stepper Motors: Discover efficient methods for employing the DRV8811 in driving stepper motors across various applications, from robotics to CNC machines.

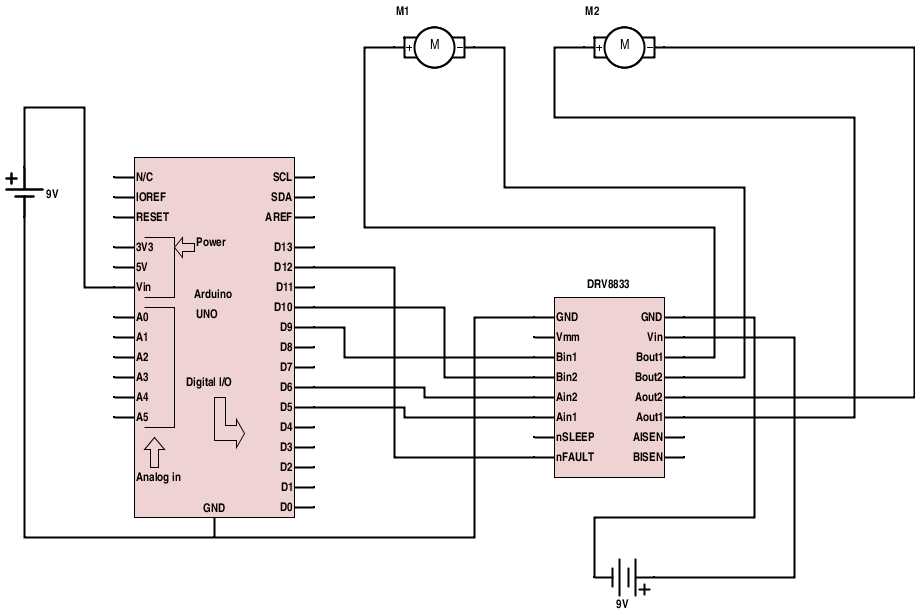

- Brushed DC Motor Control: Explore the seamless integration of the DRV8811 in controlling brushed DC motors for precise motion control in industrial automation and automotive systems.

2. Implementation Tips

- Optimizing Performance: Learn strategies for optimizing the performance of the DRV8811 through careful consideration of motor characteristics, current sensing, and PWM frequency adjustment.

- Thermal Management: Gain insights into effective thermal management techniques to ensure the reliable operation of the DRV8811 in demanding environments.

By examining these application examples and implementation tips, engineers and hobbyists can enhance their understanding of the DRV8811’s capabilities and deploy it effectively in their projects.

Real-world Applications in Robotics and Automation

Exploring the practical utilization of cutting-edge motor control technology extends far beyond the confines of technical documentation. In the realm of robotics and automation, this innovative hardware finds its place in a myriad of real-world scenarios, driving efficiency, precision, and reliability.

Automated Manufacturing Processes

In the realm of automated manufacturing, advanced motor control systems play a pivotal role in optimizing production lines. These systems enable precise movement control, facilitating the assembly of intricate components with unparalleled accuracy. By seamlessly integrating with robotic arms and conveyor belts, they streamline the manufacturing process, reducing cycle times and enhancing overall productivity.

Autonomous Vehicles and Drones

The integration of sophisticated motor control technology has revolutionized the landscape of autonomous vehicles and drones. These systems empower vehicles to navigate complex environments with agility and precision, ensuring smooth operation and obstacle avoidance. From self-driving cars to aerial drones, the seamless coordination of motors enables these machines to execute intricate maneuvers with unparalleled finesse, paving the way for a future of autonomous transportation.

- Warehouse Automation Systems: Leveraging advanced motor control technology, warehouse automation systems optimize inventory management and order fulfillment processes, increasing operational efficiency and reducing labor costs.

- Surgical Robotics: In the field of healthcare, precision is paramount. Motor control systems enable surgical robots to perform delicate procedures with unprecedented accuracy, minimizing invasiveness and accelerating patient recovery.

- Agricultural Automation: From autonomous tractors to robotic harvesters, the integration of motor control technology revolutionizes agricultural practices, enhancing crop yield and reducing manual labor dependency.

These examples merely scratch the surface of the diverse applications of motor control technology in robotics and automation. As technological advancements continue to unfold, the boundaries of possibility in this field are continuously pushed, promising a future where automation and robotics redefine the way we work, travel, and live.