Embark on a journey into the intricate realm of engineering marvels, where precision meets innovation, and mechanics intertwine with ingenuity. Within the labyrinthine corridors of technical documentation lies a trove of knowledge waiting to be unearthed. In this chapter of exploration, we delve into the intricacies of a ubiquitous electronic component, shrouded in jargon and specifications, yet holding the key to a myriad of applications.

Peer through the veil of industry jargon and delve into the heart of mechanical craftsmanship. Here lies a narrative of gears turning, coils energizing, and circuits pulsating with purpose. Beyond mere terminology lies a tapestry of functionality, where each specification tells a story of potential and possibility.

Unravel the enigmatic details concealed within the cryptic confines of technical literature. Through the lens of understanding, decode the language of resistance, torque, and voltage ratings. Each parameter, a puzzle piece in the grand design of mechanical mastery, awaits your discerning gaze.

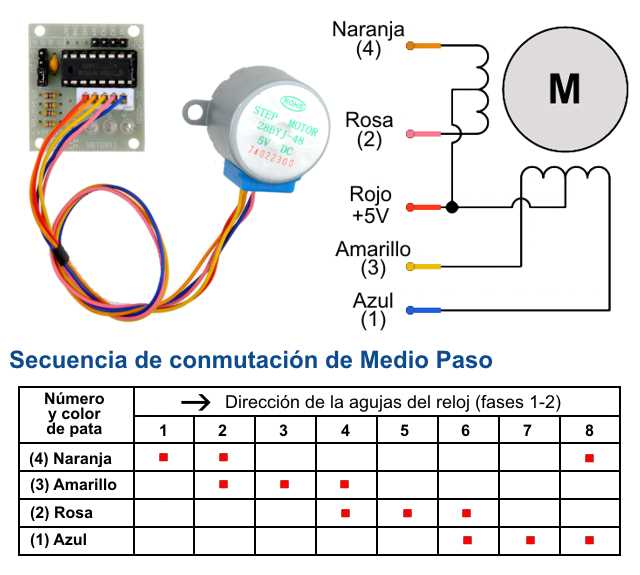

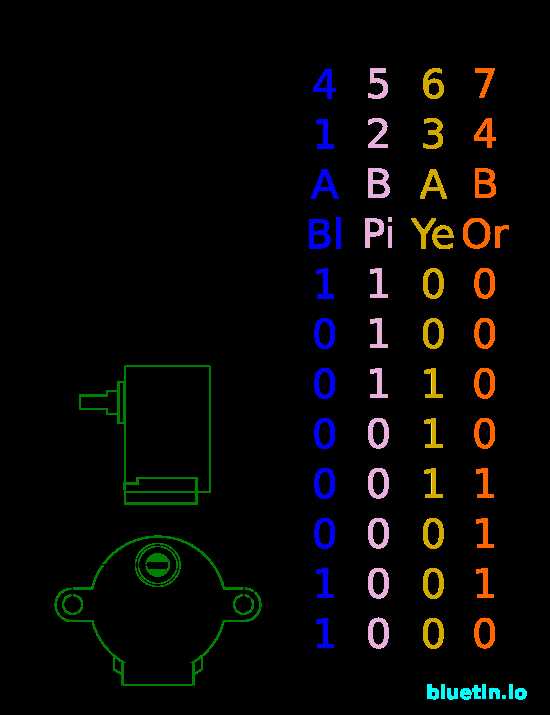

Deciphering the 28BYJ-48 Motor Documentation

In this section, we delve into the intricacies of comprehending the technical documentation associated with the 28BYJ-48 motor. Through a meticulous examination of the provided information, we aim to unravel the operational characteristics, electrical specifications, and mechanical attributes encapsulated within the datasheet.

Understanding Operational Parameters

Within the documentation, insights into the operational parameters of the motor are elucidated. These encompass vital details regarding voltage requirements, current consumption, and torque generation, offering a foundational understanding of its functionality.

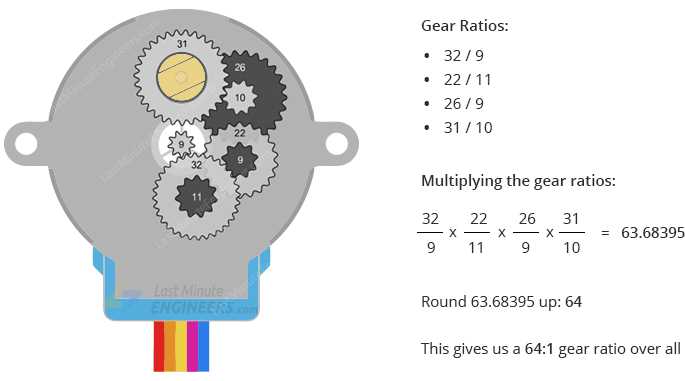

Interpreting Mechanical Specifications

Beyond the electrical realm, the datasheet furnishes a wealth of information regarding the mechanical intricacies of the 28BYJ-48 motor. From dimensions and weight to shaft configurations and step angle, each specification contributes to a comprehensive comprehension of its physical attributes and operational limitations.

Exploring Key Specifications and Features

In this section, we delve into the essential characteristics and attributes of the component, shedding light on its intricacies and functionalities. Understanding these core elements provides a comprehensive insight into its performance and potential applications.

Technical Parameters

1. Performance Metrics: Delve into the quantitative indicators that define the efficiency and efficacy of the device. These metrics encompass aspects such as torque, speed, and power consumption, offering crucial insights into its operational capabilities.

2. Mechanical Design: Explore the structural aspects that contribute to the overall functionality and durability of the component. This includes considerations such as size, weight, and material composition, all of which play pivotal roles in determining its suitability for various tasks.

Functional Features

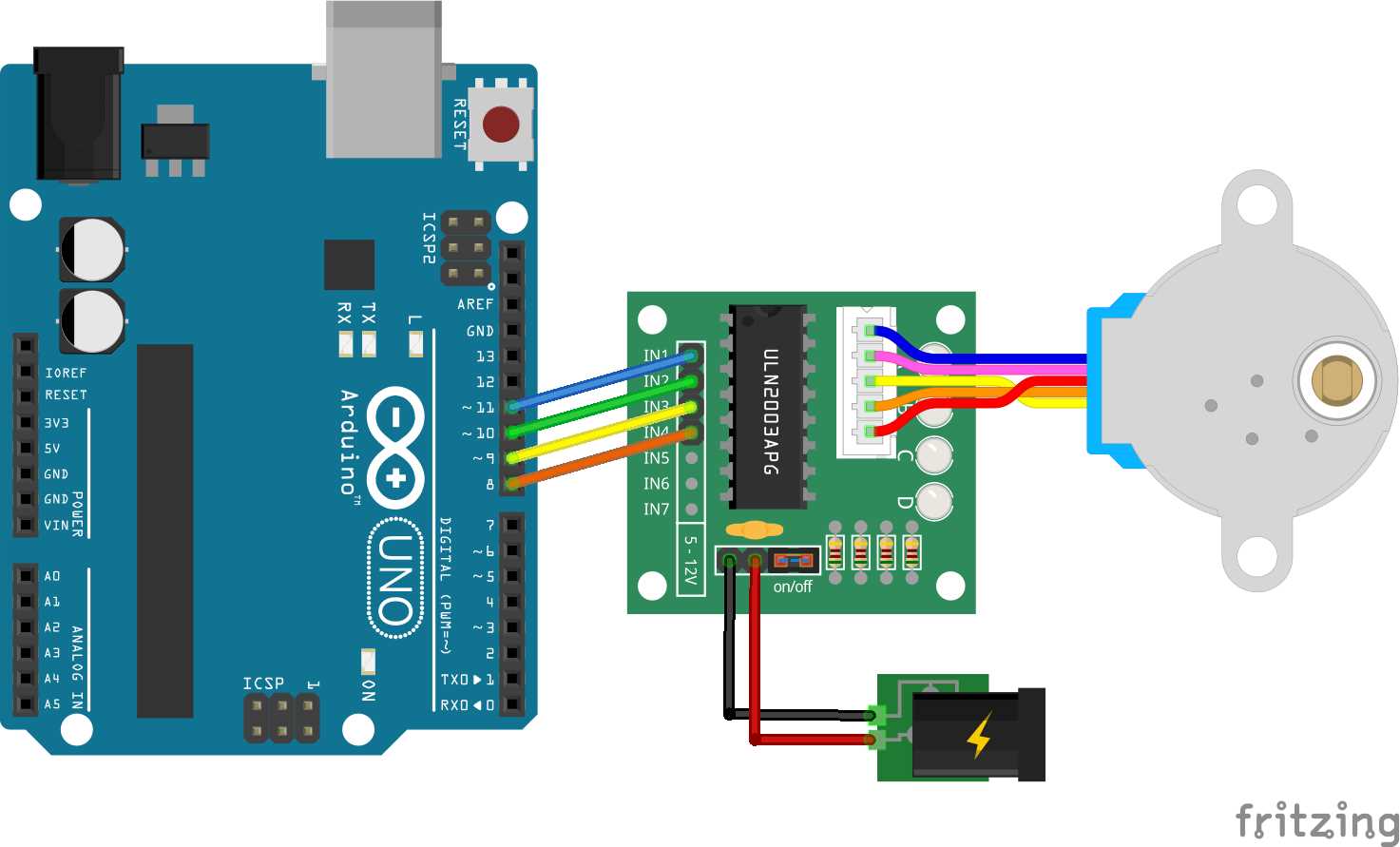

1. Control Interfaces: Examine the methods by which the device can be manipulated and regulated. This encompasses an analysis of input/output options, communication protocols, and compatibility with external systems, elucidating the ease of integration and versatility of the component.

2. Specialized Capabilities: Uncover the unique functionalities and features that set this component apart from its counterparts. Whether it’s precision positioning, microstepping capabilities, or specialized control algorithms, understanding these nuances is crucial for leveraging the full potential of the device.

Interpreting Electrical Characteristics and Performance

Understanding the intricacies of the electrical attributes and operational effectiveness of a particular component is pivotal for informed decision-making and optimal utilization. In this section, we delve into deciphering the nuanced details surrounding the electrical properties and functional performance of the device in question.

Deciphering Electrical Specifications

Delving into the numerical specifications unveils critical insights into the behavior and capabilities of the component under consideration. By meticulously examining parameters such as voltage ratings, current consumption, and impedance characteristics, one can grasp the fundamental electrical requirements and constraints governing its operation.

Evaluating Performance Metrics

Beyond the realm of raw numbers lies the realm of performance metrics, encapsulating the dynamic interplay between electrical inputs and mechanical outputs. Through rigorous analysis of factors like torque output, speed variations, and efficiency profiles, one can gauge the practical implications and potential limitations associated with integrating the component into diverse applications.

Practical Applications and Insights for Integration

Exploring the realm of practical applications and insights into the utilization of these electromechanical components unveils a plethora of possibilities for innovative implementation. Whether in the domain of automation, robotics, or precision control systems, understanding how to effectively integrate and optimize these devices is key to unlocking their full potential.

Enhancing Automation Efficiency

One notable application lies within the realm of automation, where these components serve as integral components for precise motion control. By leveraging the inherent precision and versatility of these mechanisms, industries can streamline processes, minimize errors, and enhance overall operational efficiency. Whether in manufacturing assembly lines, 3D printers, or CNC machines, the strategic incorporation of these motors facilitates seamless automation, enabling precise positioning and synchronized movements.

Optimizing Control Systems

Beyond automation, these motors find extensive utility in various control systems, where precision and reliability are paramount. Integrating them into feedback loops allows for fine-tuning of parameters, ensuring optimal performance across diverse applications. From camera stabilization systems to telescope tracking mechanisms, the versatility of these motors empowers engineers to design intricate control systems capable of adapting to dynamic environments and maintaining precise alignment.

Incorporating these electromechanical marvels into real-world scenarios demands careful consideration of factors such as torque requirements, step resolution, and power consumption. By leveraging comprehensive knowledge of their capabilities and limitations, engineers can effectively harness the potential of these components to drive innovation and efficiency across a myriad of applications.