Delving into the intricate realm of advanced electronic components, this article embarks on a journey to unravel the mysteries encapsulated within the technological marvels that empower modern machinery. Within these pages, we navigate through the labyrinth of innovation, seeking insight into the profound capabilities concealed beneath the surface of silicon and circuitry.

Embark with us on a voyage through the enigmatic landscape of precision engineering, where every component plays a vital role in the symphony of functionality. As we embark on this quest for understanding, we transcend mere documentation, delving into the essence of innovation itself.

Prepare to embark on an intellectual odyssey, where the boundaries of comprehension are continually pushed, and the pursuit of knowledge knows no bounds. Through meticulous analysis and insightful exploration, we illuminate the path towards a deeper understanding of the mechanisms that drive technological progress.

The Essence of Key Components in HR4988 Motor Control Module Documentation

Exploring the pivotal components within the technical documentation of the HR4988 motor control module reveals a wealth of foundational information essential for understanding its operation and integration.

Key Specifications and Performance Metrics

Unveiling the core specifications of the HR4988 module illuminates its operational boundaries and capabilities. Through detailed analysis, engineers can ascertain the module’s compatibility with various motor types and its efficiency in managing power consumption.

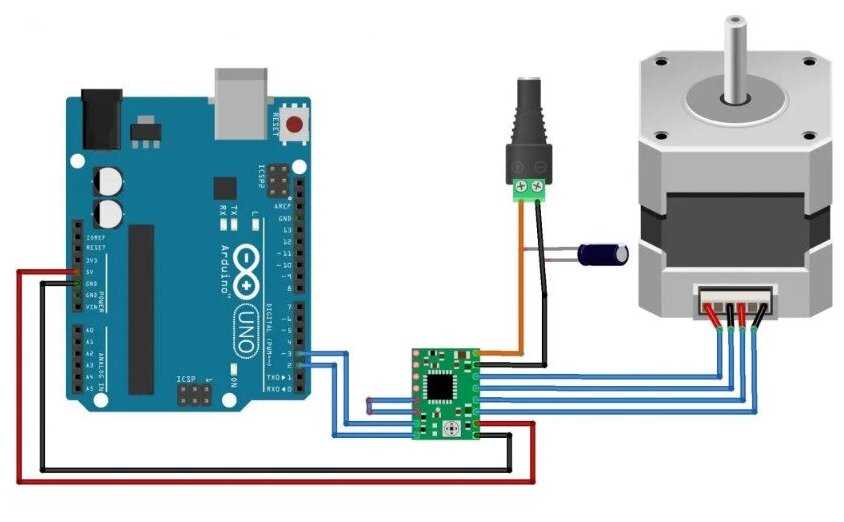

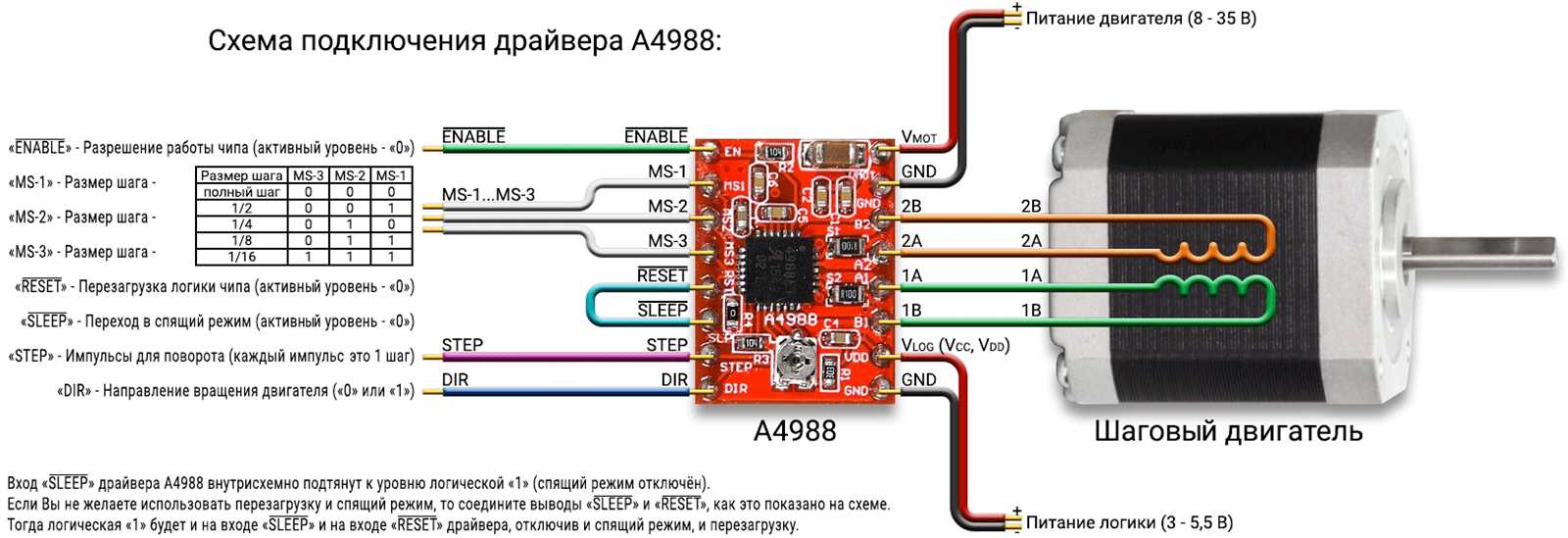

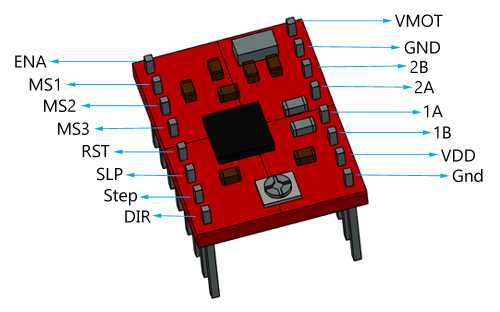

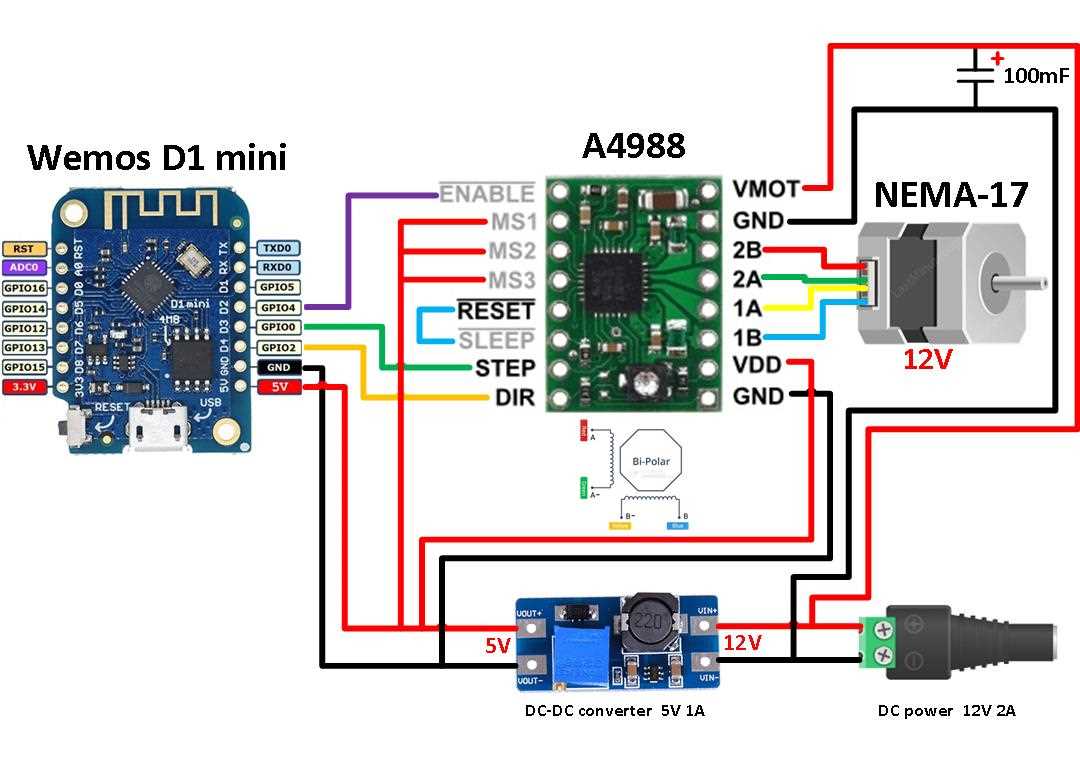

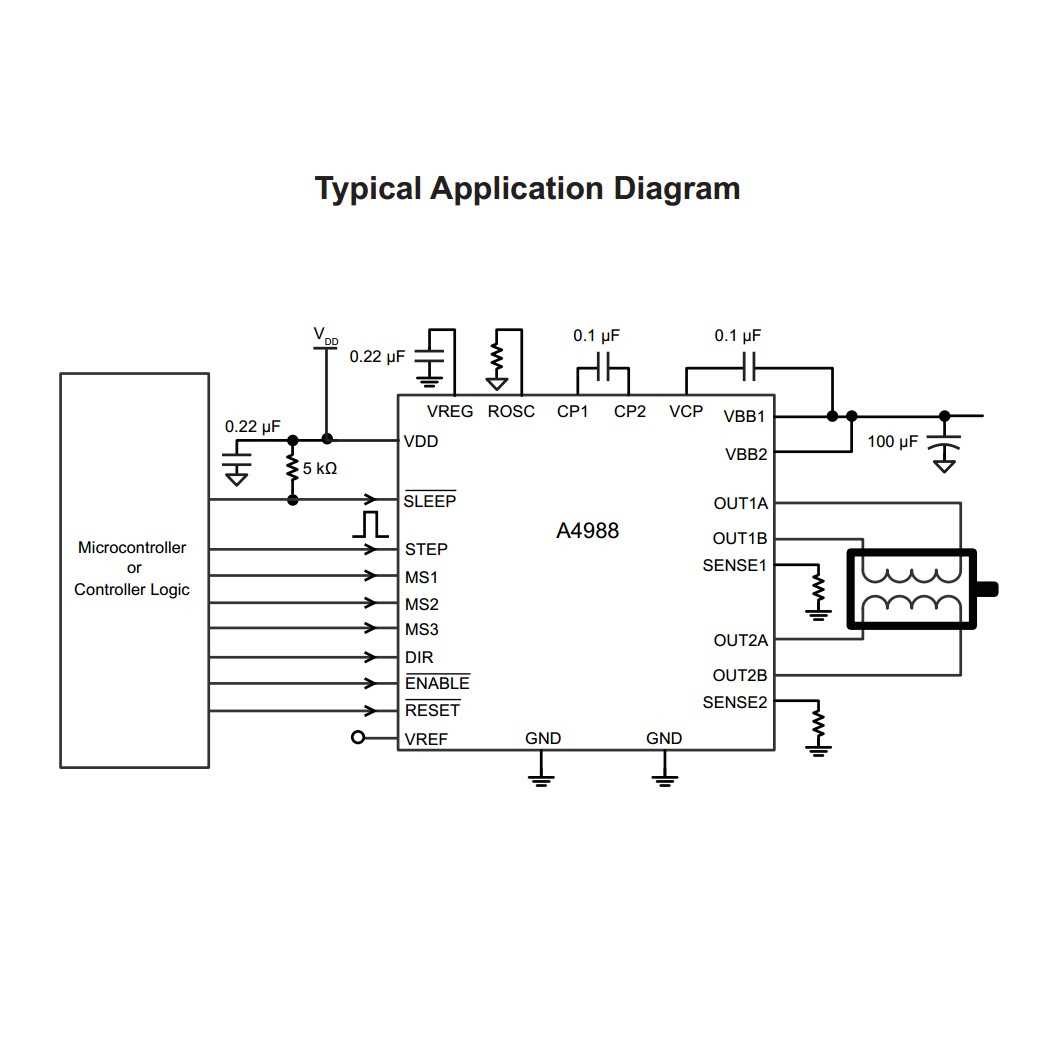

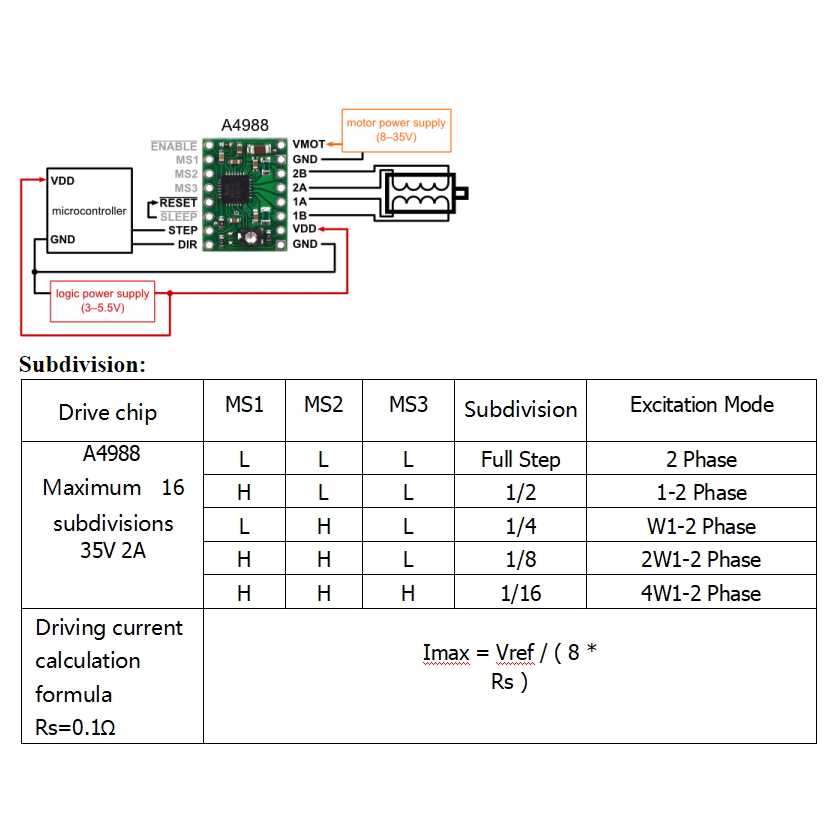

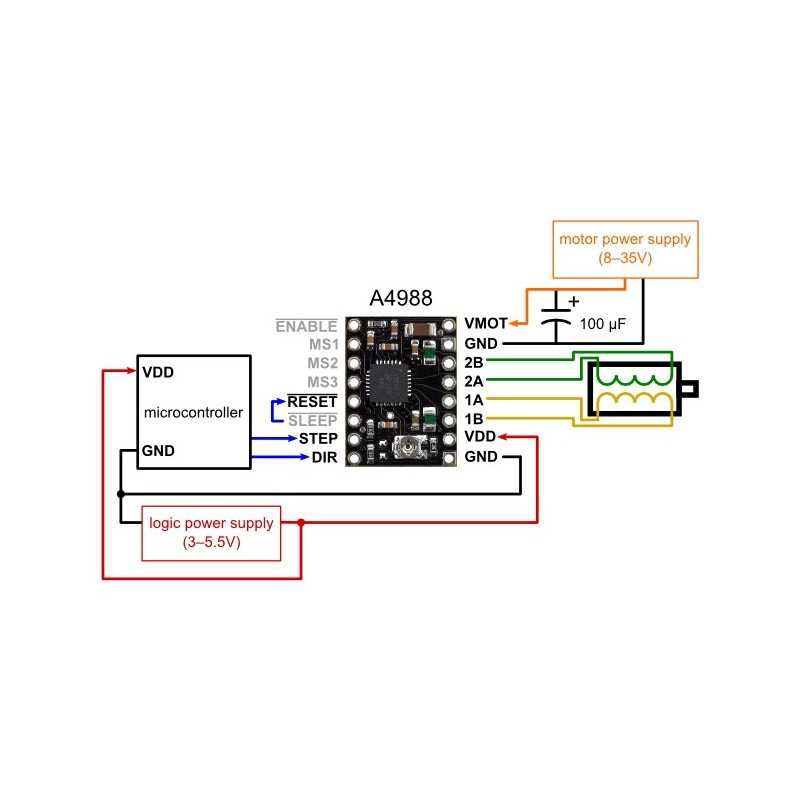

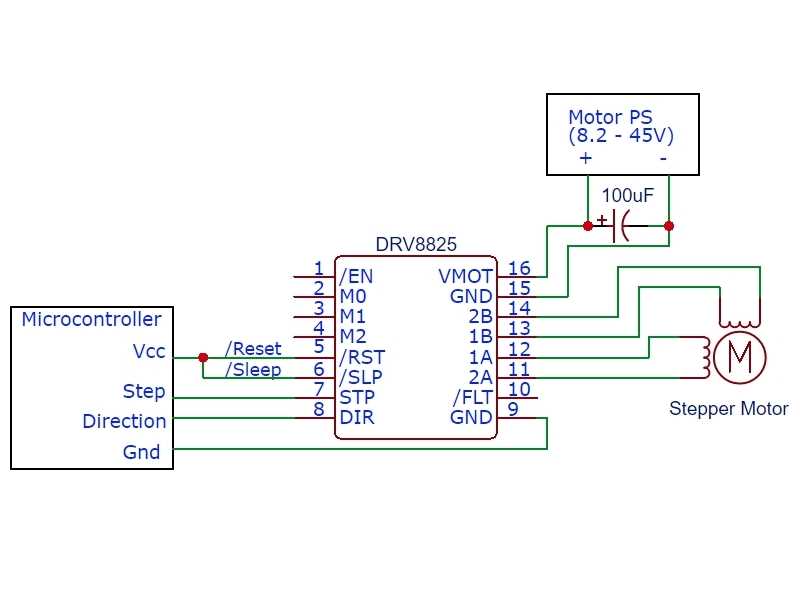

Functional Diagram and Pin Configuration

Delving into the functional diagram provides insights into the interplay of components and signals within the module, offering a roadmap for integration and troubleshooting. Coupled with the pin configuration details, this section elucidates the module’s physical connectivity and signal flow, empowering designers to harness its potential effectively.

Understanding the Core Specifications

In delving into the intricacies of this component’s essential specifications, we embark on a journey to unravel its fundamental characteristics and functionalities. By comprehending these core parameters, users gain a profound insight into the capabilities and limitations of this particular device, facilitating informed decision-making and optimized utilization.

Key Performance Metrics

Within the realm of this device’s specifications lie pivotal metrics that dictate its operational prowess. These metrics encompass factors such as efficiency, accuracy, and reliability, which collectively define its performance under various operating conditions. Understanding these metrics empowers users to gauge the device’s suitability for specific applications and anticipate its behavior in diverse scenarios.

Functional Overview

Beyond numerical values, a nuanced understanding of the functional aspects of this component is paramount. This entails grasping the underlying mechanisms governing its operation, including signal processing, power management, and thermal regulation. Such comprehension elucidates not only how the device interacts with external systems but also how it maintains stability and longevity over prolonged usage.

Exploring Application Guidelines and Recommendations

In this section, we delve into the intricacies of effectively utilizing the apparatus in question, focusing on best practices and suggestions for optimal performance. We outline practical advice and insightful strategies to harness the full potential of the technology at hand.

- Understanding Operational Parameters:

- Maximizing Efficiency:

- Ensuring Compatibility:

- Enhancing Performance:

- Maintaining Reliability:

Before embarking on any project involving this particular component, it is imperative to comprehend the fundamental operating parameters. This encompasses a thorough grasp of its capabilities, limitations, and nuances.

To achieve optimal efficiency in the application of this tool, it is essential to implement strategies that minimize wastage and maximize output. This involves meticulous planning, resource allocation, and adherence to established protocols.

Compatibility between various elements within the system is crucial for seamless functionality. Careful consideration must be given to compatibility issues, including voltage requirements, signal compatibility, and physical interface specifications.

Striving for peak performance necessitates the implementation of techniques aimed at enhancing the overall efficacy of the system. This may involve fine-tuning parameters, optimizing algorithms, or employing supplementary components to augment functionality.

Reliability is paramount in any application, and proactive measures must be taken to mitigate potential sources of failure. This includes regular maintenance, adherence to recommended operating conditions, and contingency planning.

By adhering to these application guidelines and recommendations, users can leverage the full potential of the technology, ensuring seamless integration and optimal performance in diverse operational scenarios.

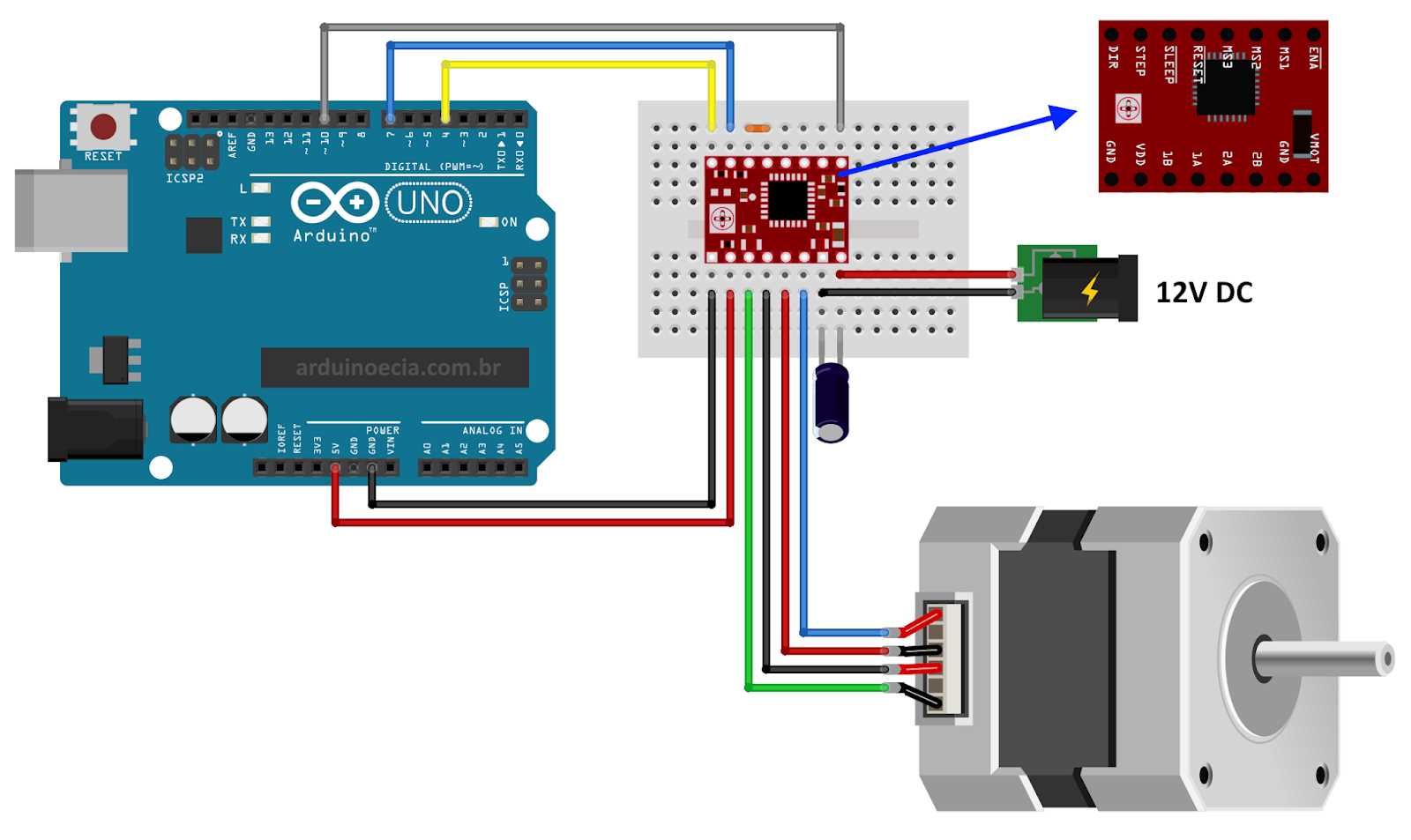

Integration and Troubleshooting Tips

In this section, we’ll delve into strategies for seamless incorporation of your stepper motor control system and address common issues that may arise during the integration process. We’ll explore techniques to optimize performance, identify potential pitfalls, and provide remedies for troubleshooting challenges.

- Ensure seamless incorporation of your motor control system by carefully aligning components and verifying compatibility.

- Calibrate your system meticulously to maximize efficiency and accuracy, minimizing the margin for error.

- Monitor voltage levels and current draw consistently to preempt potential electrical issues.

- Inspect connections regularly to mitigate the risk of loose or faulty wiring compromising system integrity.

- Implement adequate cooling mechanisms to prevent overheating and safeguard against component damage.

Addressing troubleshooting concerns requires a systematic approach:

- Start by isolating the problematic component or subsystem through systematic testing and analysis.

- Refer to comprehensive documentation and resources to identify common failure modes and corresponding solutions.

- Engage with online forums and communities to leverage collective expertise and gain insights into resolving specific issues.

- Experiment with alternative configurations and settings to pinpoint the root cause of the problem and explore potential workarounds.

- Consider seeking professional assistance or consulting with technical support channels if challenges persist despite exhaustive troubleshooting efforts.

By integrating these tips into your workflow and troubleshooting methodology, you can streamline the integration process and enhance the reliability and performance of your stepper motor control system.