Unlocking the full potential of your equipment requires more than just routine maintenance. It demands a meticulous selection of lubricants tailored to the intricate needs of your machinery. In the dynamic landscape of industrial operations, the efficacy of lubrication transcends mere fluidity. It epitomizes the synergy between engineering precision and chemical innovation, ensuring seamless performance across diverse applications.

Embark on a journey towards optimized machinery functionality, where each component thrives in harmony with its counterparts. Explore the intricate chemistry of high-grade lubricants, meticulously engineered to surpass conventional boundaries. Through meticulous formulation and rigorous testing, these lubricants embody the pinnacle of technological advancement, delivering unparalleled performance in the most demanding environments.

Elevate your understanding of lubricant specifications beyond conventional norms. Delve into the nuances of viscosity, thermal stability, and oxidative resistance, where each parameter delineates the difference between optimal operation and subpar performance. Embrace a comprehensive approach to lubrication management, where informed decisions pave the path to enhanced efficiency and prolonged machinery lifespan.

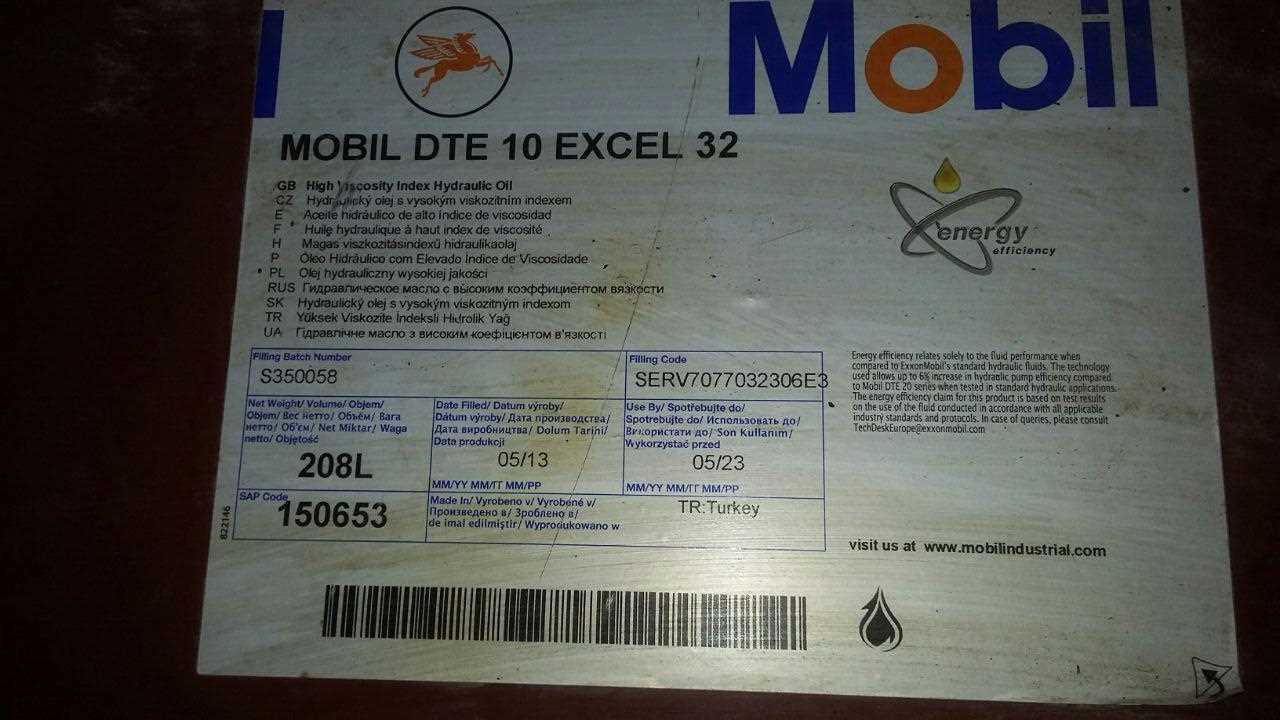

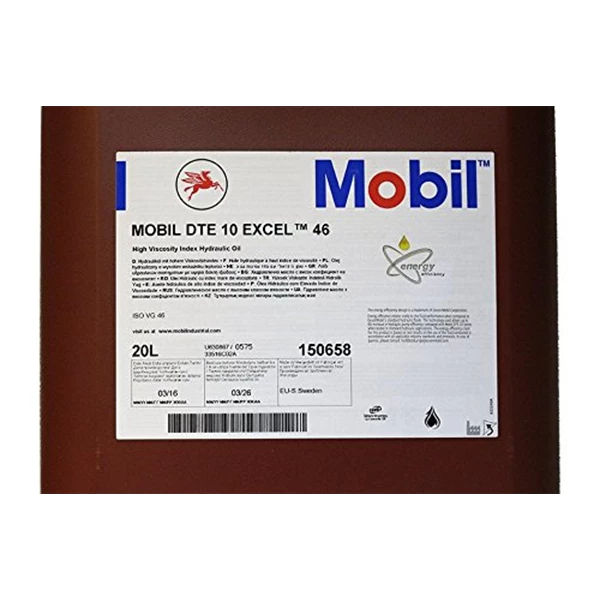

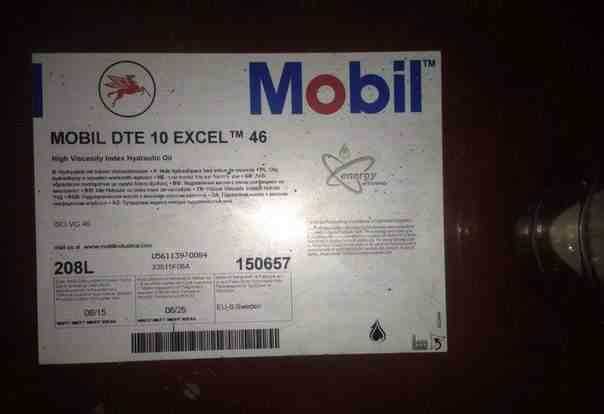

Understanding Technical Specifications of Mobil DTE 10 Excel 46

In this section, we delve into the intricacies of the documentation surrounding Mobil DTE 10 Excel 46, exploring its comprehensive technical specifications and performance indicators. Through dissecting the provided information, we aim to gain a nuanced understanding of the product’s capabilities and optimal applications.

Chemical Composition Overview

The datasheet furnishes insights into the chemical composition of the lubricant, shedding light on its constituent elements and their proportions. By comprehending the composition, users can anticipate the lubricant’s behavior in various operating conditions and environments.

Performance Characteristics

Furthermore, the datasheet elucidates the performance characteristics exhibited by Mobil DTE 10 Excel 46, elucidating parameters such as viscosity, thermal stability, and oxidative resistance. Understanding these attributes equips users to assess the lubricant’s suitability for specific machinery and operational requirements.

| Parameter | Description |

|---|---|

| Viscosity Index (VI) | An indicator of the lubricant’s viscosity-temperature relationship, facilitating performance predictions across a range of temperatures. |

| Flash Point | The temperature at which the lubricant emits sufficient vapor to ignite momentarily under specific test conditions, crucial for assessing fire risk. |

| Four-Ball Wear Test | An evaluation of the lubricant’s anti-wear properties, simulating real-world frictional conditions to ascertain its protective capabilities. |

| Oxidation Stability | A measure of the lubricant’s resistance to oxidative degradation, indicative of its longevity and reliability in prolonged usage. |

By navigating through the technical specifications provided in the datasheet, users can make informed decisions regarding the application of Mobil DTE 10 Excel 46, optimizing machinery performance and longevity.

Overview and Composition

In this section, we delve into the fundamental characteristics and components of the product, shedding light on its essential properties and internal structure. Exploring the core essence of this formulation, we aim to provide a comprehensive understanding of its makeup and functionality.

- Constituents: Unveiling the constituent elements that constitute this formulation, we dissect its composition to unveil the intricate blend of ingredients that contribute to its efficacy.

- Properties: Delving into the inherent properties of this solution, we elucidate its various attributes and qualities that render it suitable for diverse applications.

- Structure: Peering into the structural framework of the product, we elucidate the arrangement and organization of its components, offering insights into its molecular architecture.

- Functionality: Understanding the functional aspects of this formulation, we explore its mechanisms of action and how it fulfills its intended purpose in various operational contexts.

By dissecting the overview and composition of this product, we aim to provide a foundational understanding that serves as a cornerstone for further exploration and utilization.

Performance Characteristics and Applications

In this section, we delve into the operational aspects and potential uses of the product, focusing on its dynamic features and practical implementations. We explore its functionality, versatility, and relevance across various settings, offering insights into its capabilities and adaptability. Through examination and analysis, we uncover the diverse applications and performance attributes, shedding light on its effectiveness in different scenarios.

Operational Dynamics

Understanding the product’s operational dynamics is crucial in comprehending its efficacy and potential. We scrutinize its behavior under different conditions, investigating its responsiveness, stability, and consistency. By elucidating its operational intricacies, we gain a deeper appreciation of its reliability and performance.

Practical Implementations

Exploring the practical implementations of the product unveils its utility across various domains. We examine its suitability for different tasks, considering factors such as efficiency, durability, and compatibility. By identifying its practical applications, we elucidate the breadth of its functionality and its value in real-world scenarios.

Handling and Storage Recommendations

Guidelines for managing and preserving the integrity of lubricating oils are essential for ensuring optimal performance and longevity. This section outlines prudent practices to maintain the quality and usability of lubricants, safeguarding against degradation and contamination.

Proper Handling Practices

When handling lubricating oils, exercise care to prevent exposure to environmental factors that may compromise their efficacy. Ensure adequate ventilation in storage areas to mitigate the risk of moisture accumulation, which can lead to oxidation and deterioration of the oil properties. Utilize appropriate containers and dispensing equipment to minimize the introduction of contaminants during transfer and application.

Storage Conditions

Optimal storage conditions play a pivotal role in preserving the performance characteristics of lubricating oils. Store containers in a cool, dry environment away from direct sunlight and sources of heat to inhibit thermal degradation. Maintain consistent temperatures within the recommended range to prevent fluctuations that can affect viscosity and fluidity. Additionally, segregate lubricants from incompatible materials to prevent cross-contamination and ensure product integrity.