Unlocking the potential of innovative polymer blends, this discourse delves into the realm of advanced construction materials, transcending traditional boundaries to harness the power of modern engineering. Within the intricate tapestry of construction sciences lies a pivotal component, akin to the mortar binding bricks, yet far more versatile and dynamic in its applications.

Embark on a journey through the nuanced landscape of adhesive formulations, where each compound intricately tailored to meet the demands of contemporary infrastructure projects. Beyond the conventional confines of adhesive properties, lies a narrative woven with resilience, longevity, and adaptability, attributes paramount in an ever-evolving construction milieu.

Explore the synergy between science and engineering, as we dissect the core principles underpinning the adhesive prowess. Through the lens of innovation, we unravel the complexities of material cohesion, adhesion, and elasticity, offering a glimpse into the transformative potential encapsulated within.

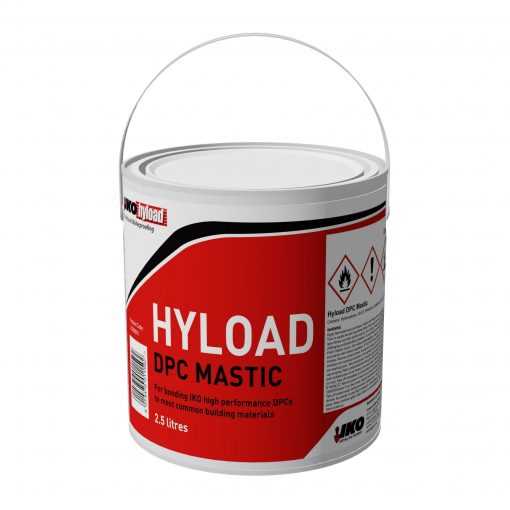

Understanding the Specifications of HT Mastic 500: A Comprehensive Overview

In this section, we delve into a detailed examination of the technical characteristics and performance attributes of the HT Mastic 500. Through a comprehensive analysis, we aim to provide a thorough understanding of its specifications, facilitating informed decision-making and optimized utilization.

Key Performance Indicators

- Performance Metrics

- Technical Parameters

- Functional Attributes

The specifications of the HT Mastic 500 offer insights into its capabilities and suitability for various applications. By exploring its key performance indicators, users can grasp the range of tasks it can efficiently undertake and the environments in which it excels.

Technical Analysis

- Material Composition

- Temperature Resistance

- Chemical Compatibility

Delving deeper into the technical realm, we dissect the composition of the HT Mastic 500, its resistance to extreme temperatures, and compatibility with various chemicals. Understanding these intricacies is paramount for ensuring optimal performance and longevity in diverse operating conditions.

Key Properties and Composition of HT Mastic 500

In this section, we delve into the essential characteristics and makeup of the HT Mastic 500, exploring its defining features and the elements that constitute its formulation.

Thermal Stability: The HT Mastic 500 exhibits remarkable resistance to elevated temperatures, ensuring its integrity and performance even in demanding thermal environments.

Chemical Resilience: This specialized compound demonstrates a robust resistance to various chemical agents, safeguarding against corrosive substances and enhancing its longevity in challenging industrial settings.

Flexibility and Adhesion: An inherent trait of the HT Mastic 500 lies in its flexibility and exceptional adhesive properties, facilitating easy application and ensuring strong bonding to diverse surfaces.

Electrical Insulation: With its unique composition, the HT Mastic 500 serves as an effective electrical insulator, guarding against electrical currents and enhancing safety in electrical applications.

Composition Overview: While detailed specifics are beyond the scope of this overview, the HT Mastic 500 comprises a meticulously crafted blend of polymers, fillers, and additives, synergistically combined to achieve its superior properties.

In conclusion, understanding the key properties and composition of HT Mastic 500 provides valuable insights into its suitability for a wide range of industrial and commercial applications, where thermal stability, chemical resilience, and electrical insulation are paramount.

Applications and Industries Utilizing HT Mastic 500

In various sectors and fields, there is a growing reliance on specialized solutions like HT Mastic 500 to meet demanding requirements and enhance performance. This section explores the diverse applications and industries that benefit from the unique properties and capabilities offered by this advanced product.

1. Industrial Manufacturing

Within the realm of industrial manufacturing, HT Mastic 500 finds extensive application in enhancing the efficiency and durability of processes and products. Its versatility and adaptability make it indispensable in a range of manufacturing processes, from sealing and bonding components to providing insulation and protection against extreme conditions.

2. Construction and Infrastructure

The construction and infrastructure sectors leverage HT Mastic 500 to address critical challenges in building projects and infrastructure development. Whether used in sealing joints and seams to ensure structural integrity or providing corrosion resistance in harsh environments, this innovative solution contributes to the longevity and reliability of construction projects.

- Roofing and Waterproofing

- Concrete Repair and Protection

- Bridge and Highway Maintenance

Moreover, HT Mastic 500 plays a vital role in the maintenance and repair of existing structures, extending their service life and reducing the need for frequent interventions.

Performance and Durability: Real-world Case Studies

In this section, we delve into tangible examples of how the performance and resilience of the HT mastic have been demonstrated in various practical scenarios. Through real-world case studies, we explore the efficacy and longevity of this versatile product without relying solely on technical specifications or numerical data.

Enhanced Structural Integrity

One notable case study showcases the remarkable enhancement of structural integrity achieved through the application of the HT mastic. By examining instances where traditional materials failed under stress or environmental pressures, we unveil how the mastic’s innovative properties provided robust reinforcement, prolonging the lifespan of diverse structures.

Longevity in Challenging Environments

Another compelling narrative emerges from examining the prolonged durability of materials treated with the HT mastic in challenging environments. Through meticulous observation of real-world settings, ranging from extreme weather conditions to corrosive atmospheres, we uncover compelling evidence of the product’s ability to withstand and outlast conventional alternatives.