Unveiling the core of motion innovation, this exploration delves into the heart of a revolutionary component and its remarkable capabilities. Within the realm of electrical engineering, lies a silent hero, orchestrating the symphony of movement through circuits with unparalleled finesse. Far from a mere mechanical cog, this enigmatic device embodies precision, reliability, and versatility, propelling a myriad of applications into realms previously deemed impossible.

Embracing the marriage of electrons and motion, this narrative navigates through the intricate pathways of power transmission, unraveling the secrets of efficient energy conversion. Amidst the realm of technological marvels, this unsung champion silently commands the forces of nature, translating electrical signals into tangible kinetic energy with seamless efficiency. Its prowess extends beyond conventional boundaries, breathing life into creations spanning industries and disciplines.

Discover the silent conductor, hidden within the intricate tapestry of modern innovation. Beyond its humble appearance lies a powerhouse of potential, awaiting the deft touch of engineers and enthusiasts alike. As we embark on this journey of discovery, prepare to witness the fusion of theory and practice, unlocking the gates to a world where ingenuity reigns supreme.

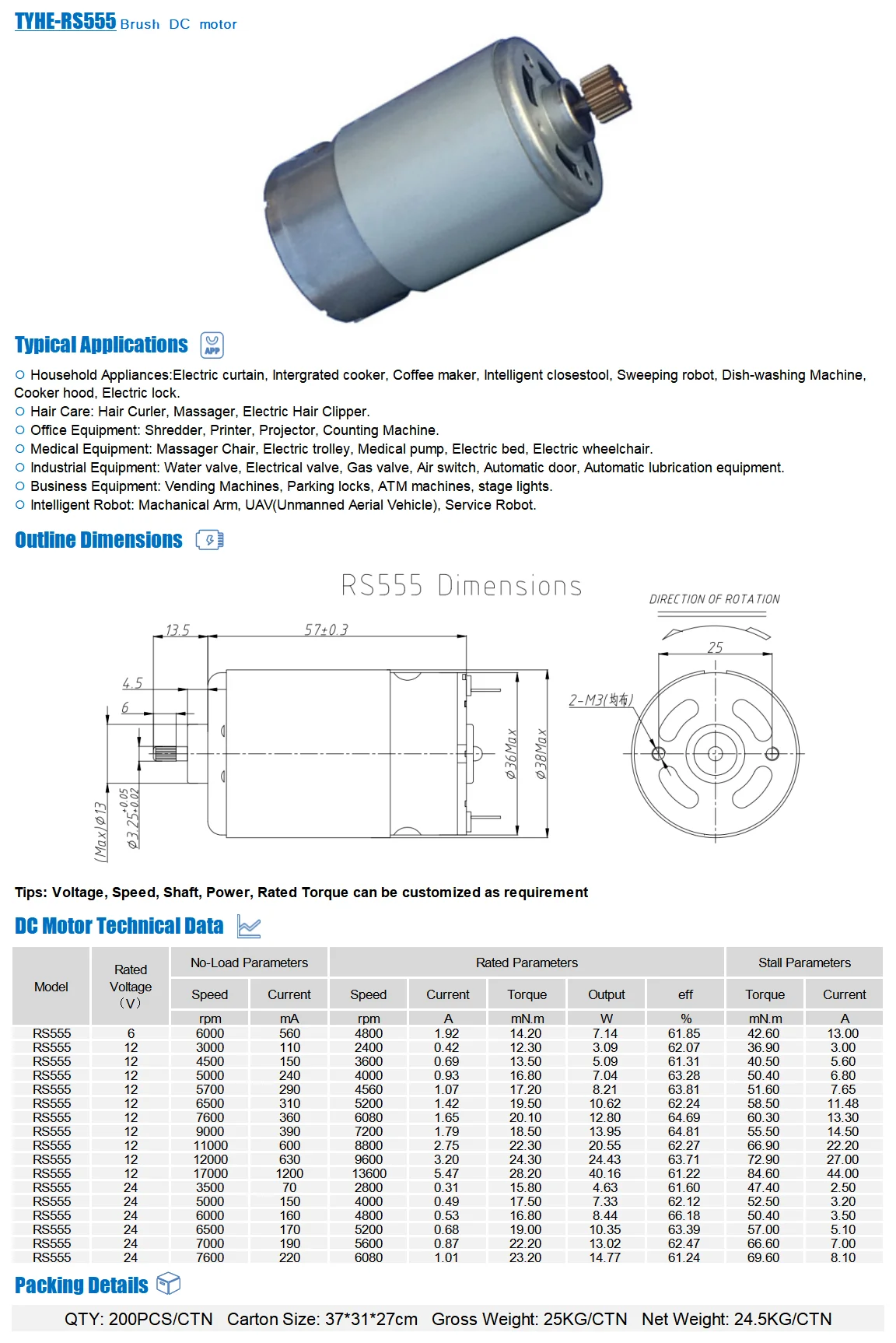

Understanding DC Motor Specifications

When delving into the realm of electronic machinery, comprehending the intricacies of DC motor specifications becomes paramount. These specifications serve as the cornerstone for selecting, configuring, and optimizing the performance of electromechanical systems.

The Essence of DC Motors

Essentially, DC motors are the dynamic heartbeats of countless mechanical applications, driving motion with precision and efficiency. Through the interplay of electrical currents and magnetic fields, these devices convert electrical energy into mechanical power, propelling machinery forward with finesse.

Deciphering Specifications

Deciphering the array of specifications accompanying DC motors requires a keen eye for detail and a deep understanding of their significance. These specifications, akin to a motor’s DNA, delineate its performance characteristics, operational parameters, and compatibility with various applications. From torque to efficiency ratings, each metric holds pivotal importance in the realm of electromechanical design.

Deciphering Technical Documentation for Direct Current Rotational Engines

In this section, we’ll embark on a journey to unravel the intricacies of deciphering technical documentation associated with small-scale rotational devices powered by direct current. Understanding the nuances and intricacies buried within these documents is paramount for any enthusiast, hobbyist, or professional aiming to harness the full potential of these versatile mechanisms.

Let’s delve into the essential elements that comprise these documents, exploring terminology, specifications, and performance indicators. By grasping the significance of each component and parameter, we can effectively navigate through the wealth of information provided, enabling informed decision-making and optimal utilization of these rotary power sources.

- Terminology Deconstruction: Dissecting the Lexicon of Direct Current Propulsion

- Deciphering Performance Metrics: Unveiling the Enigmatic Symbols

- Understanding Operational Characteristics: Mapping the Behavior Patterns

- Interpreting Application Guidelines: Unlocking the Potential

Through a systematic exploration of these aspects, we aim to empower individuals with the knowledge and proficiency required to harness the capabilities of direct current rotational engines to their fullest extent. By demystifying the technical documentation, we pave the way for innovation, experimentation, and advancement in the realm of motorized applications.

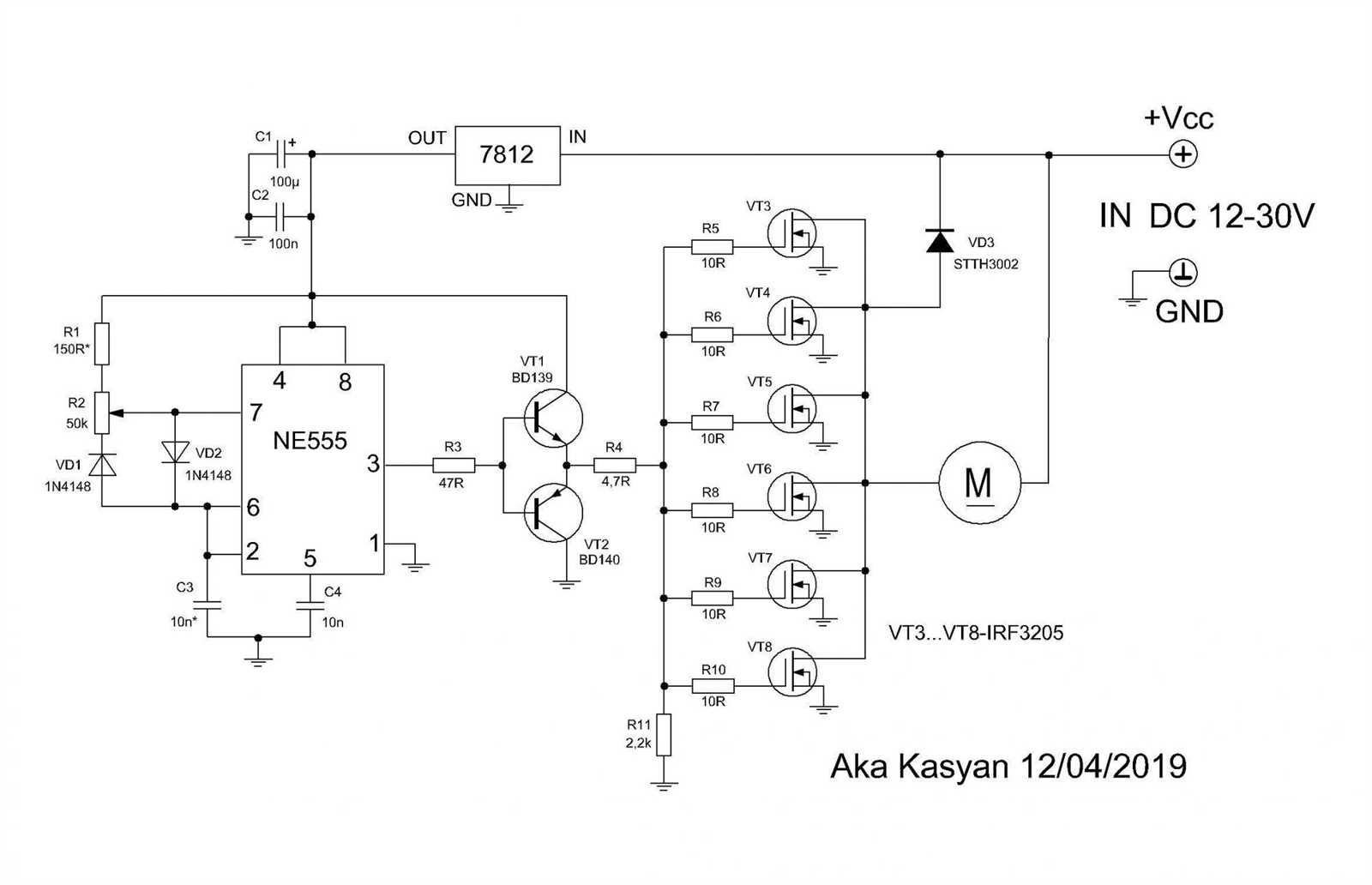

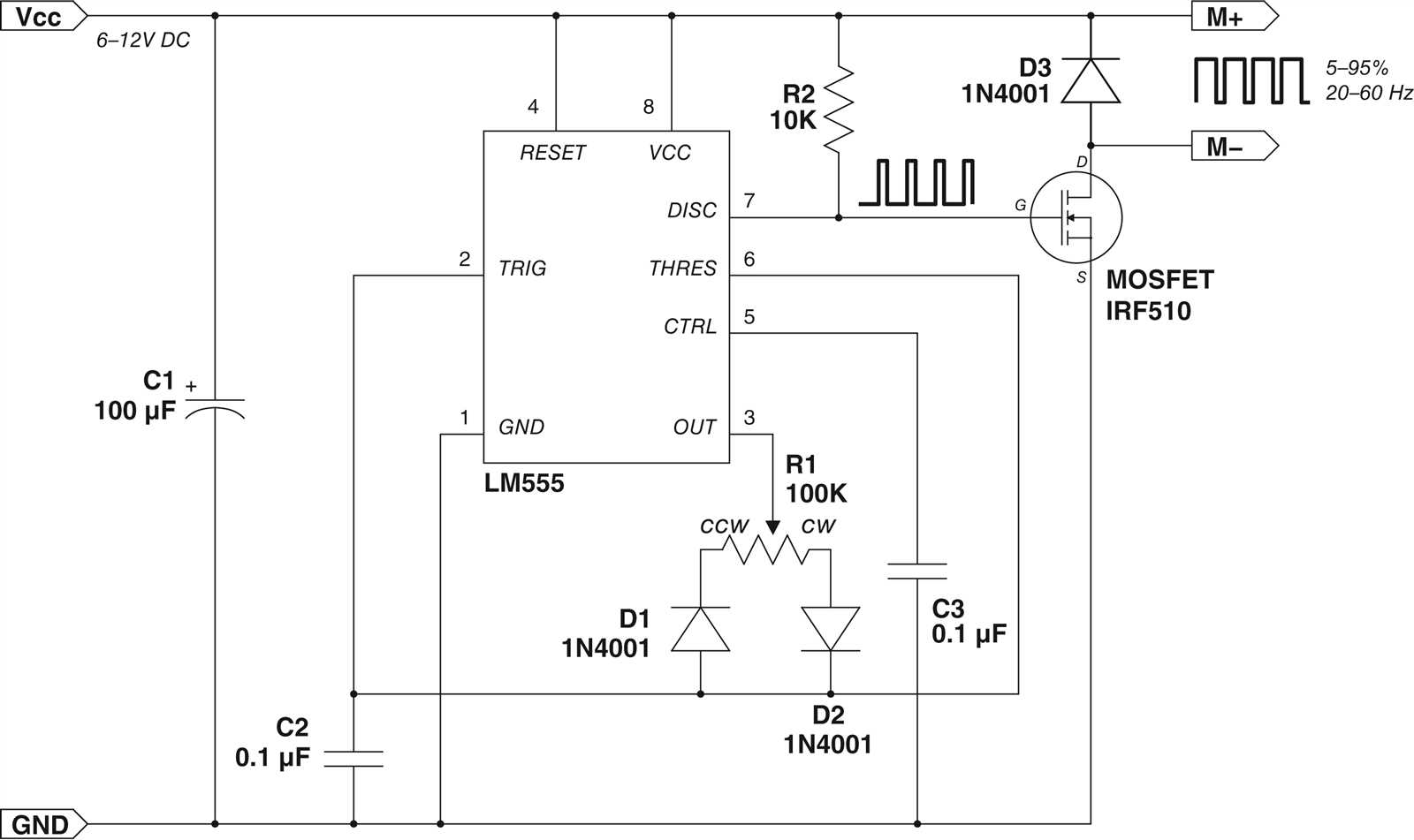

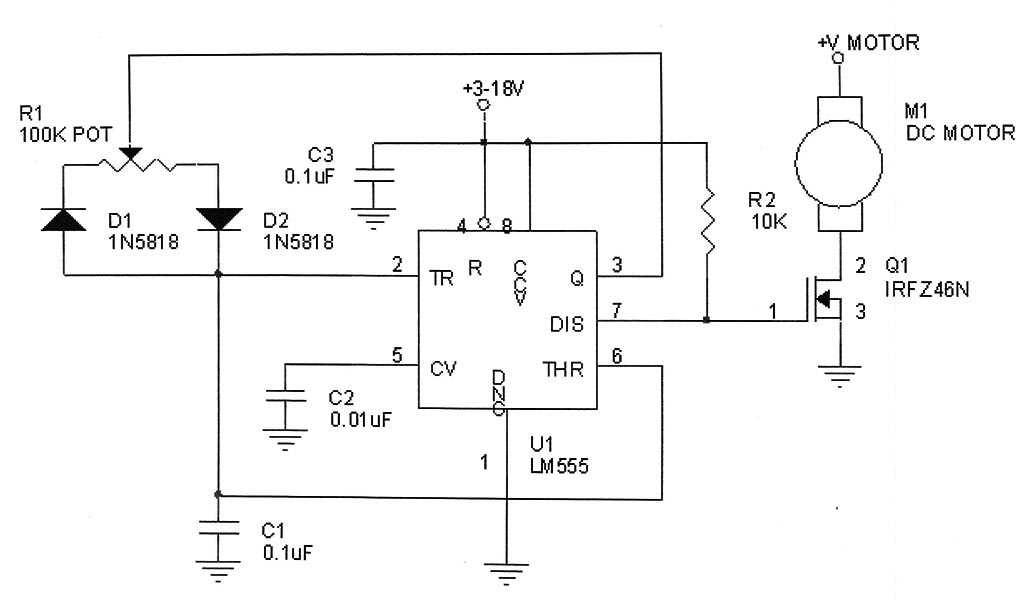

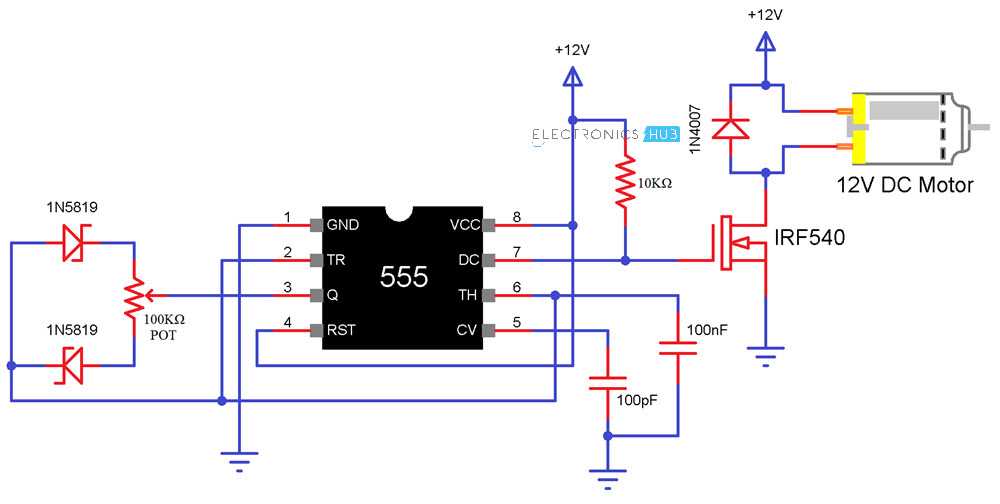

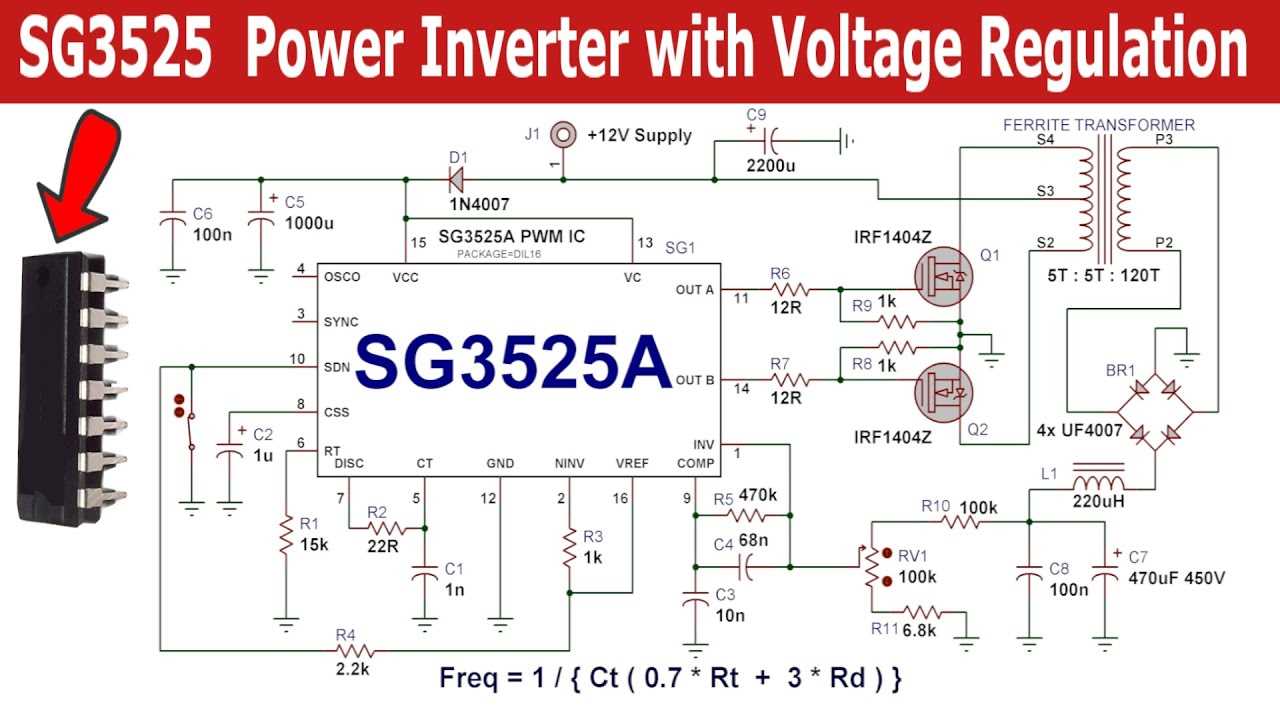

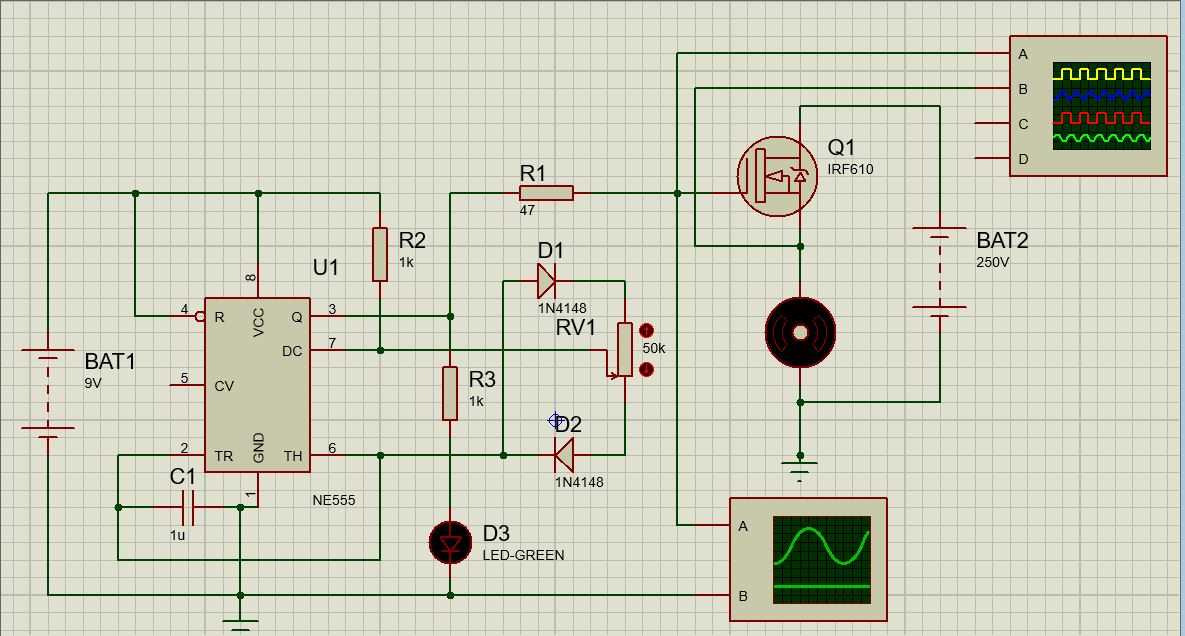

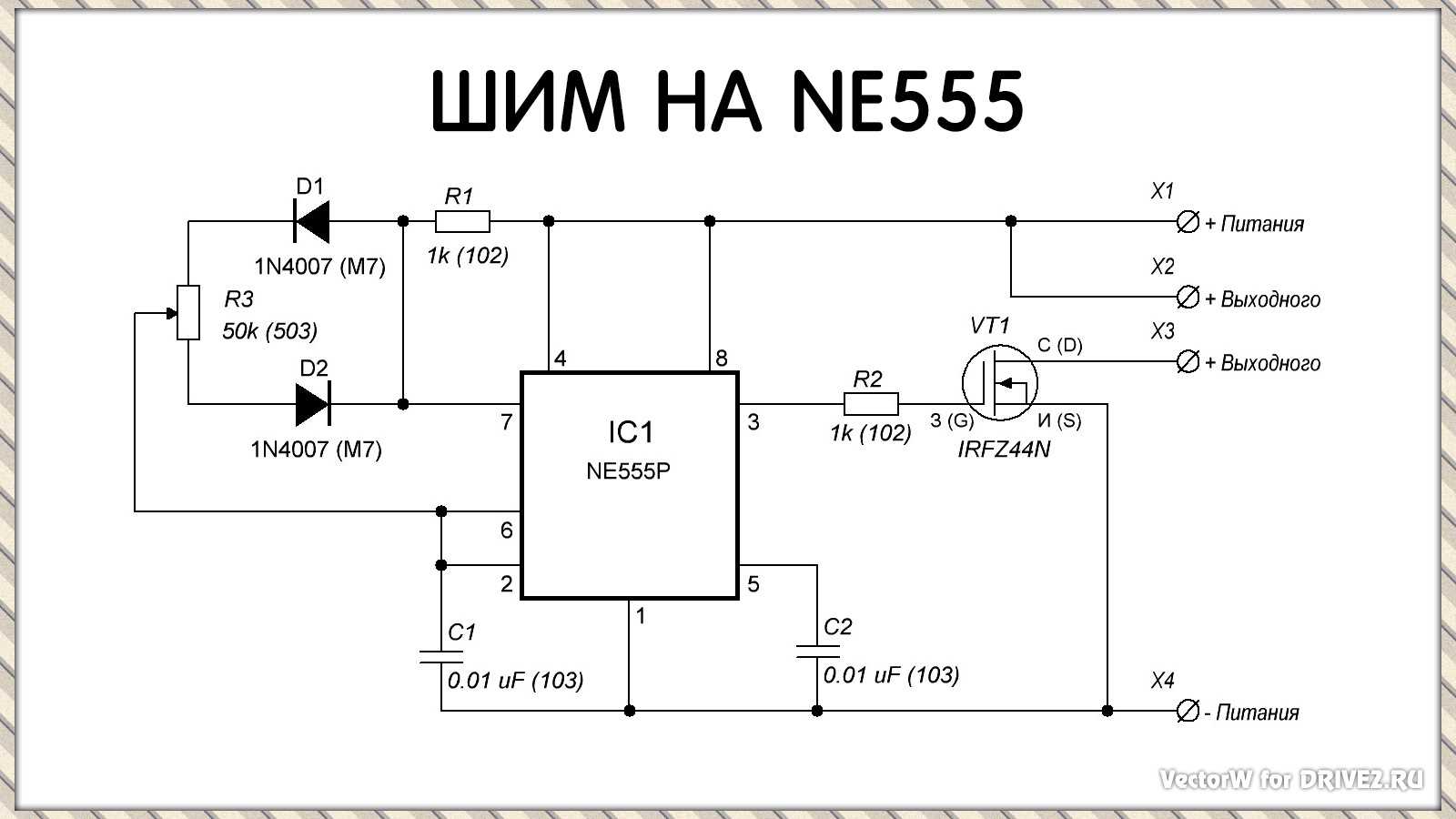

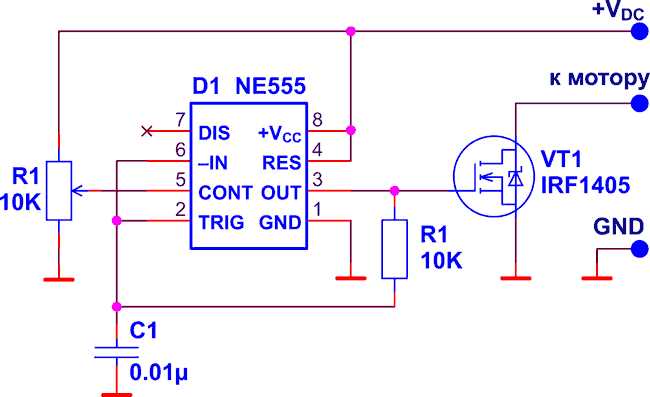

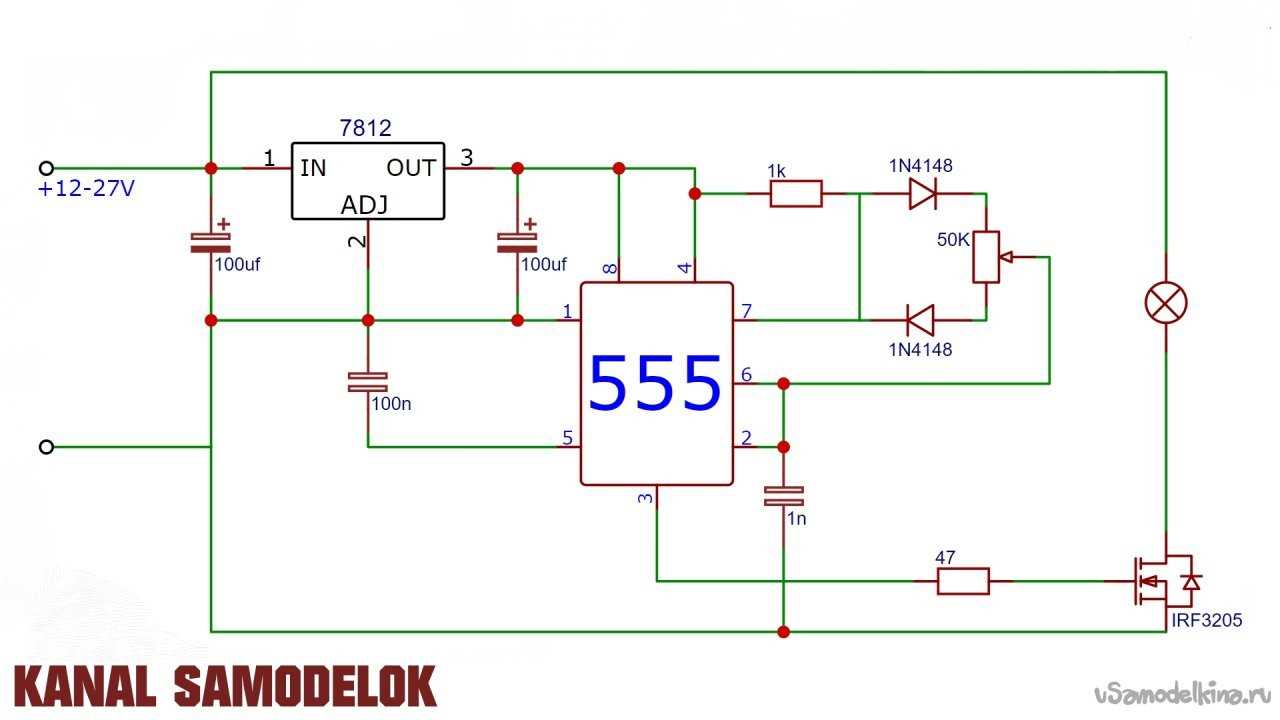

Optimizing Performance with 555 DC Motors

In the pursuit of enhancing operational efficiency and maximizing the capabilities of direct current (DC) motors, exploring methods for fine-tuning performance becomes imperative. This section delves into strategies for refining the functionality and efficacy of these electromechanical devices, steering clear of the mundane confines of standard specifications.

Enhancing Operational Efficiency

- Exploring techniques to elevate the efficiency quotient

- Fine-tuning operational parameters for optimal output

- Implementing strategies to mitigate energy wastage

Maximizing Functional Capabilities

- Unveiling avenues for expanding the operational spectrum

- Investigating methods to augment torque and rotational speed

- Deploying innovative mechanisms to enhance responsiveness

Key Factors for Optimal Performance

In the pursuit of maximizing the effectiveness and longevity of any electromechanical system, attention to specific metrics and criteria is paramount. This section delves into the fundamental parameters essential for achieving peak operational efficiency and reliability.

1. Electrical Input

Power Supply: The voltage and current characteristics supplied to the system play a pivotal role in determining its performance. Understanding the ideal voltage range and current limitations ensures optimal utilization of electrical resources.

2. Mechanical Considerations

Load Characteristics: The load placed upon the system, encompassing factors such as torque requirements and rotational speed, profoundly impacts its efficiency. Balancing these mechanical demands with the motor’s capabilities is crucial for sustained operation.

Practical Applications of DC Motors: Ingenious Implementations

Exploring the versatile applications of these electrical workhorses unveils a realm of ingenuity in engineering and innovation. Harnessing the power of rotational motion, these devices find utility across a spectrum of domains, propelling various mechanisms with efficiency and precision.

Automation Advancements

One significant realm where DC motors shine is in automation, where they act as pivotal components driving the seamless operation of machinery. From conveyor belts in manufacturing plants to robotic arms in assembly lines, these motors execute tasks with dexterity and consistency, streamlining processes and enhancing productivity.

Mobile Robotics Marvels

In the realm of mobile robotics, DC motors serve as the dynamic force behind locomotion. Powering wheels and propellers, they navigate diverse terrains, enabling the movement of robots for exploration, surveillance, and logistics. Their adaptability to varying loads and speeds ensures agile and responsive maneuvers, essential for tasks ranging from search and rescue missions to warehouse management.

Embodying reliability and versatility, DC motors manifest as indispensable assets across industries, embodying the epitome of efficiency and innovation.