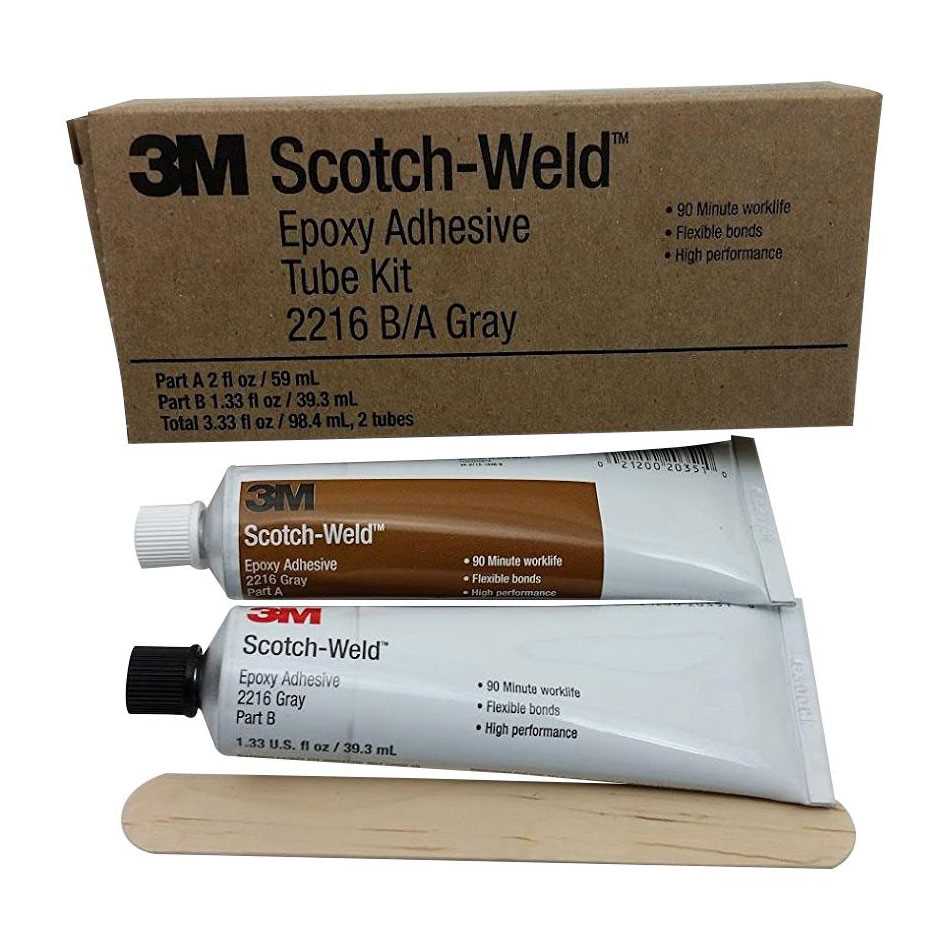

Within the realm of advanced bonding solutions, there exists a remarkable innovation that defies the restraints of traditional adhesives. Introducing the cutting-edge 3M 2216 epoxy compound – a revolution in bonding technology that surpasses expectations with its unparalleled versatility and exceptional performance. This transformative adhesive offers a myriad of applications across various industries, making it an indispensable asset for engineers, manufacturers, and DIY enthusiasts alike.

Delve into the world of this groundbreaking epoxy compound, and unlock a vast array of possibilities. With its strong adhesion and superior strength, it effortlessly bonds materials together, creating robust connections that withstand the test of time. Whether you are working with metal, ceramics, plastics, or wood, the 3M 2216 epoxy compound seamlessly merges different substrates, enabling the creation of durable and long-lasting structures.

But the incredible attributes of the 3M 2216 epoxy compound do not end there. This extraordinary adhesive boasts impressive resistance to impact, vibration, and temperature extremes, guaranteeing its reliability even in the harshest of environments. Its remarkable flexibility allows it to adapt to the ever-changing demands of various applications, ensuring seamless integration in any project.

Understanding the Key Properties of 3M 2216 Epoxy

When it comes to the remarkable substance known as 3M 2216 epoxy, it is crucial to thoroughly comprehend its essential characteristics. By gaining an in-depth understanding of the fundamental properties of this versatile material, users can effectively harness its potential in various applications.

Exploring the unique attributes of 3M 2216 epoxy is vital for those seeking to utilize its remarkable capabilities. By delving into its distinct qualities and comprehending their significance, individuals can make informed decisions regarding its potential applications.

One of the key aspects to consider when evaluating 3M 2216 epoxy is its adhesive strength. This remarkable substance possesses an unparalleled bonding capability, allowing it to create strong and durable connections. Understanding the adhesive strength of 3M 2216 epoxy enables users to select the appropriate application methods and materials for their specific needs.

In addition to its exceptional adhesive properties, the chemical resistance of 3M 2216 epoxy is another vital characteristic to explore. This substance showcases impressive resistance to various chemicals, ensuring its stability and reliability even in challenging environments. By recognizing its chemical resistance, individuals can confidently employ 3M 2216 epoxy in applications where exposure to harsh solvents or corrosive substances is anticipated.

Furthermore, understanding the thermal stability of 3M 2216 epoxy is crucial for its successful implementation. This material exhibits excellent heat resistance, allowing it to withstand elevated temperatures without compromising its structural integrity. By comprehending its thermal stability, users can confidently incorporate 3M 2216 epoxy in applications that involve high-temperature conditions.

Lastly, it is essential to explore the electrical conductivity of 3M 2216 epoxy. This substance showcases unique electrical properties that make it an excellent choice for applications that require conductivity and insulation properties simultaneously. By recognizing its electrical conductivity, users can effectively employ 3M 2216 epoxy in electronic and electrical applications with confidence.

In conclusion, a comprehensive understanding of the key properties of 3M 2216 epoxy is essential for harnessing its full potential in various applications. By exploring its adhesive strength, chemical resistance, thermal stability, and electrical conductivity, individuals can confidently select and utilize this remarkable substance according to their specific requirements.

Overview of 3M 2216 Epoxy

In this section, we will provide an overview of the highly versatile and reliable adhesive product known as 3M 2216 Epoxy. This advanced compound offers exceptional bonding properties, making it an ideal choice for a wide range of industrial and commercial applications.

Features

When it comes to high-performance adhesives, the 3M 2216 Epoxy stands out due to its remarkable features. This adhesive offers excellent strength, durability, and resistance to chemicals and extreme temperatures. Its versatile nature makes it suitable for a variety of surfaces, including metal, plastic, ceramics, and composites.

Applications

With its exceptional adhesive properties, the 3M 2216 Epoxy finds application in various industries. It is commonly used in manufacturing and assembling electronic components, providing reliable bonding of circuit boards, connectors, and other critical parts. This epoxy is also widely utilized in aerospace, automotive, and construction industries, enabling secure and long-lasting bonding in challenging environments.

To further illustrate the versatility of 3M 2216 Epoxy, here are some specific applications where its unique properties are valuable:

| Industry | Application |

|---|---|

| Electronics | Sealing and encapsulating sensitive components |

| Aerospace | Bonding composite panels and structures |

| Automotive | Ensuring secure adhesion of plastic or metal parts |

| Construction | Joining concrete, metal, or fiberglass elements |

In conclusion, the 3M 2216 Epoxy is a superior adhesive known for its exceptional strength, durability, and resistance to extreme environments. Its wide range of applications across various industries makes it a highly reliable choice for bonding critical components and materials.

Physical Properties and Applications

In this section, we will explore the various physical properties and potential applications of the 3M 2216 epoxy adhesive. This adhesive is known for its exceptional durability and reliable performance in a wide range of industries. Here, we will discuss its characteristics without directly referencing its specific product name.

Superior Strength and Durability

This adhesive exhibits remarkable strength and durability, making it suitable for demanding applications in industries such as construction, automotive, and aerospace. Its robust formulation ensures that it can withstand high levels of stress and mechanical forces, providing long-lasting bonds that can withstand extreme conditions.

Excellent Chemical Resistance

The 3M 2216 epoxy adhesive also demonstrates outstanding chemical resistance, allowing it to resist the corrosive effects of different substances. This property makes it ideal for use in environments where exposure to chemicals, such as oils, solvents, or acids, is common. The adhesive’s ability to withstand chemical attacks provides added protection and ensures the longevity of bonded surfaces.

Furthermore, its versatility enables it to be utilized across a wide range of applications. From bonding structural components to sealing joints and repairing equipment, this epoxy adhesive offers reliable performance and exceptional adhesion to various materials, including metals, ceramics, and composites.

Overall, the 3M 2216 epoxy adhesive is recognized for its superior strength, durability, and chemical resistance. Its broad range of applications makes it a valuable asset in various industries, providing efficient bonding solutions that meet the highest standards of quality and reliability.

Important Safety Considerations for Using the 3M 2216 Epoxy

When working with the powerful and versatile adhesive known as the 3M 2216 Epoxy, it is crucial to prioritize safety. This section will highlight key safety considerations to keep in mind when handling this reliable bonding agent.

Protective Gear: To ensure personal safety, it is essential to wear appropriate protective gear. This includes gloves, safety glasses, and protective clothing. By shielding yourself from potential exposure to the epoxy, you can minimize the risk of skin irritation or eye damage.

Ventilation: Proper ventilation is vital when using the 3M 2216 Epoxy. Working in a well-ventilated area, such as an open space or with the aid of an exhaust system, helps prevent inhaling hazardous fumes that can arise during the adhesive’s application or curing process.

Handling and Storage: Safely handling and storing the 3M 2216 Epoxy is crucial to prevent accidents. It is important to carefully follow the manufacturer’s instructions regarding temperature and humidity conditions. Additionally, always ensure proper sealing and labeling of the epoxy container to avoid any confusion or unintended use.

Fire Safety: The 3M 2216 Epoxy is flammable and poses a fire hazard. Keep the adhesive away from open flames, sparks, or any sources of ignition. In case of a fire, use appropriate extinguishing methods, such as foam, carbon dioxide, or dry chemical agents, and seek help from trained professionals if needed.

Disposal: After completing the epoxy application, proper disposal is crucial. Follow local regulations and guidelines to ensure safe and environmentally friendly disposal of any unused or waste epoxy. Avoid pouring it down the drain or disposing of it in regular trash bins.

By adhering to these important safety considerations, users can confidently work with the 3M 2216 Epoxy while minimizing potential risks to themselves, others, and the environment. Prioritizing safety ensures a productive and secure bonding experience with this highly effective adhesive.