In the realm of electronic engineering, there exists a vital component silently orchestrating the intricate dance of motion control systems. This unsung hero, akin to a conductor guiding an orchestra, interfaces between the realms of microcontrollers and the physical world, translating digital commands into tangible movement. Without delving into specific nomenclature, let us embark on a journey to explore the essence of this enigmatic facilitator, whose significance reverberates across industries and applications.

Within the realm of electronic propulsion, an indispensable ally emerges, offering a conduit for the manifestation of precise motion sequences. Like a master artisan wielding a chisel, this intermediary component carves the path for innovation in robotics, automation, and beyond. Its influence extends beyond mere mechanical manipulation, delving into realms where precision and reliability reign supreme.

As we peel back the layers of abstraction, a realm of complexity unfolds, revealing a symphony of electrical signals choreographed with precision. Each pulse, a note in the composition of motion, harmonizes with the next to orchestrate a ballet of movement. Through the lens of exploration, let us navigate the intricacies of this silent conductor, unraveling its mysteries and illuminating its significance in the grand tapestry of technology.

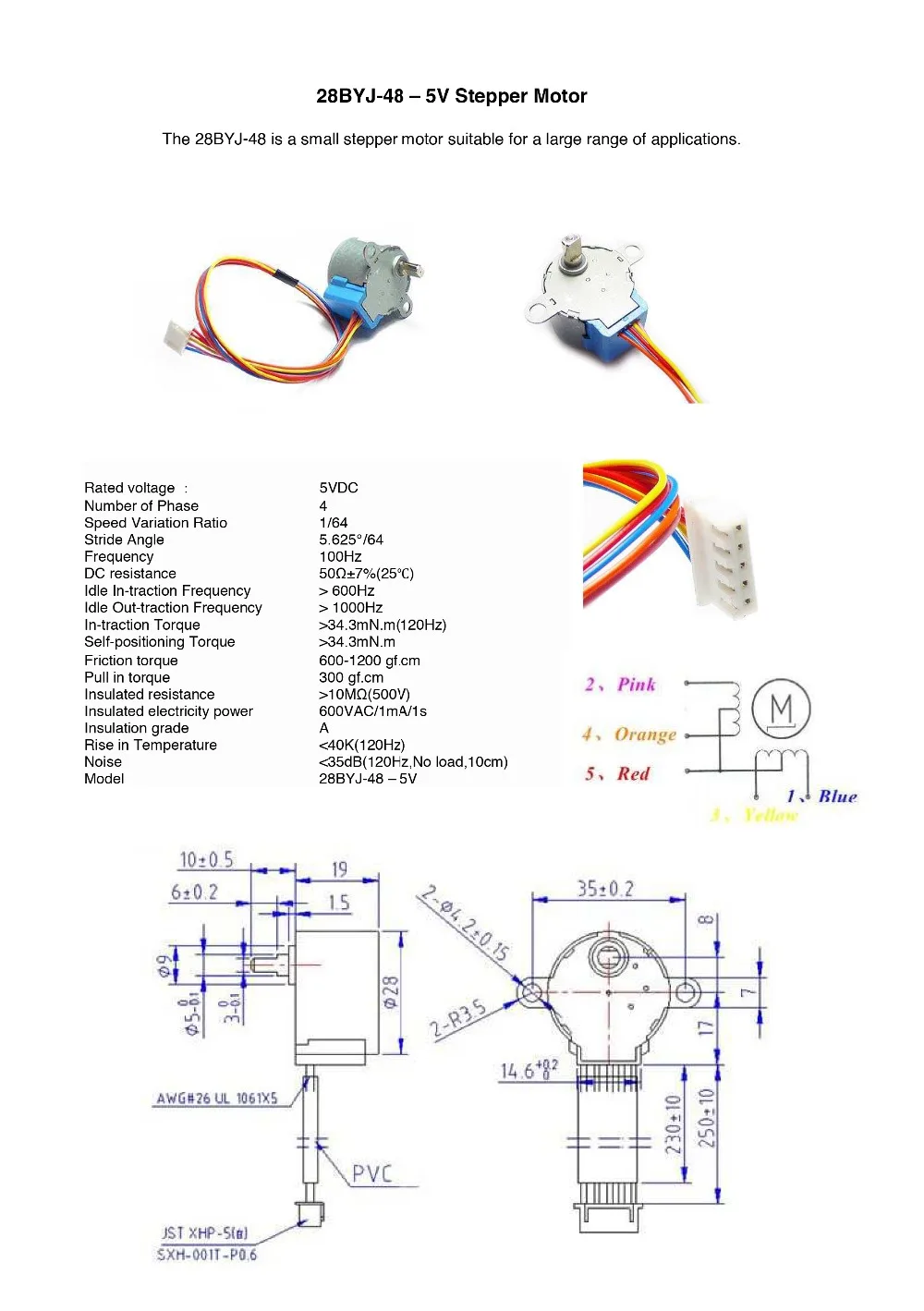

Understanding the 28BYJ-48 Stepper Motor

In this section, we delve into comprehending the intricacies of the 28BYJ-48 stepper motor, a versatile component widely utilized in various electromechanical applications. Our exploration centers on deciphering its operational principles, functionality, and practical applications without direct reference to technical specifications or datasheets.

Operational Dynamics

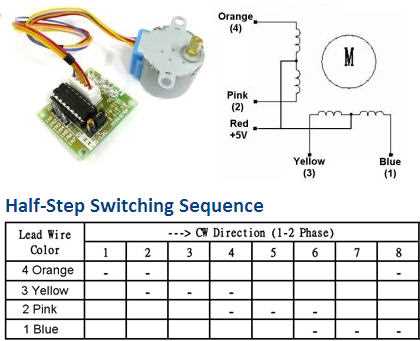

At the heart of the 28BYJ-48 stepper motor lies a complex interplay of electromagnetic forces and mechanical components, orchestrating precise and controlled rotational motion. Understanding its operational dynamics entails dissecting the interaction between coils, rotor, and stator, elucidating how pulses of current translate into incremental steps, enabling precise positioning and movement.

Applications and Implementations

The versatility of the 28BYJ-48 stepper motor transcends conventional boundaries, finding application in diverse realms such as robotics, automation, and DIY projects. Exploring its myriad implementations unveils its adaptability and reliability, whether in driving robotic arms, controlling 3D printers, or automating industrial processes. Furthermore, its compatibility with driver modules like the ULN2003 broadens its utility spectrum, facilitating seamless integration into a plethora of projects.

| Aspect | Characteristic |

|---|---|

| Step Angle | 5.625°/64 |

| Holding Torque | ≥ 34.3mN·m |

| Operating Voltage | 5V DC |

| Driver Compatibility | ULN2003 |

This HTML section offers an insightful exploration into understanding the operational dynamics and versatile applications of the 28BYJ-48 stepper motor without relying on specific technical terms like “28BYJ-48,” “ULN2003,” or “datasheet.”

The Basics of Stepper Motors and Their Applications

Stepper motors represent a pivotal component in numerous technological applications, orchestrating precise movements through a series of discrete steps. Understanding their fundamental principles unveils a gateway to a myriad of industrial, robotic, and consumer electronics innovations. This section delves into the essence of stepper motors, elucidating their operational principles, diverse applications, and significance across various domains.

Operational Principles: Stepper motors operate on a fascinating principle, leveraging electromagnetism to generate controlled motion. Unlike traditional motors, which rely on continuous rotation, steppers execute movements in discrete increments, allowing for precise positioning and synchronization. The interaction between coils and magnetic fields orchestrates this intricate dance, granting engineers unparalleled control over motion.

Applications in Industry and Beyond: The versatility of stepper motors finds expression across a spectrum of industries and applications. From robotic arms in manufacturing facilities to precision instruments in medical equipment, their ability to execute precise movements with repeatability makes them indispensable. Moreover, stepper motors empower innovations in 3D printing, CNC machining, and automation, driving efficiency and accuracy in modern production processes.

Exploring Future Frontiers: As technology advances, the role of stepper motors continues to evolve, ushering in new possibilities and applications. From advancements in microstepping technology to integration with artificial intelligence algorithms, the future promises even greater precision, efficiency, and adaptability. Explorations into nanoscale manipulation, space exploration, and wearable devices hint at the boundless potential of stepper motors in shaping tomorrow’s technological landscape.

Conclusion: Stepper motors stand as a testament to the marriage of precision engineering and electromagnetism, offering a cornerstone for innovation across industries. Understanding their fundamentals not only unlocks the door to current applications but also paves the way for future advancements. As technology marches forward, the humble stepper motor remains an enduring symbol of progress and possibility.

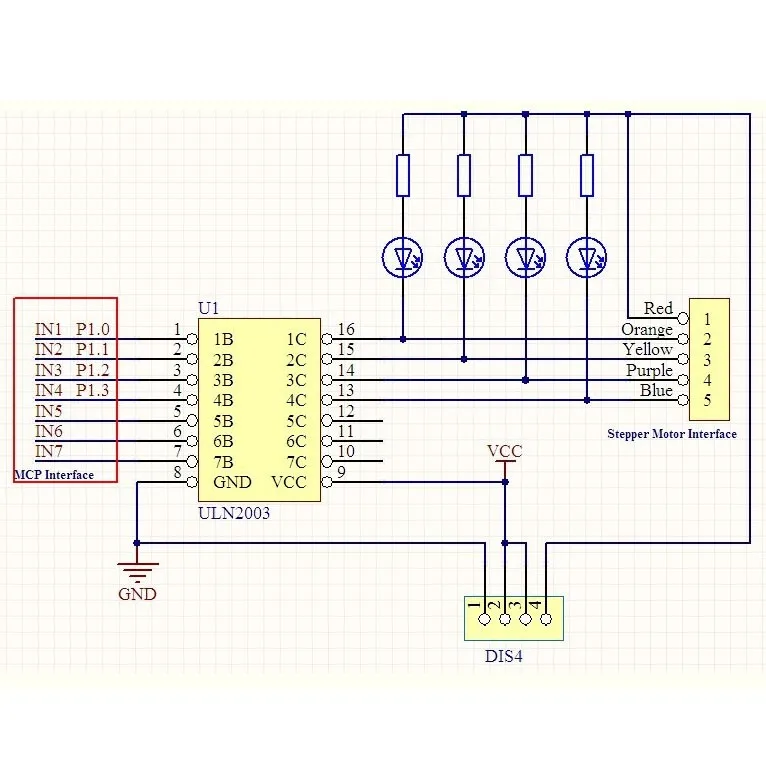

Exploring the ULN2003 Driver Module

Delve into the intricacies of a pivotal component in your projects with an in-depth exploration of the ULN2003 Driver Module. This section ventures into the operational principles, functional aspects, and application scenarios of this indispensable module, shedding light on its role in driving various electromechanical systems.

Understanding the Module’s Functionality

- Unravel the underlying mechanisms that empower the ULN2003 Driver Module to interface with microcontrollers and control a plethora of devices.

- Explore the architecture and internal circuitry of the module, deciphering how it facilitates seamless integration within diverse electronic setups.

Applications in Real-World Projects

- Survey the myriad applications of the ULN2003 Driver Module across industries, from robotics and automation to prototyping and DIY endeavors.

- Gain insights into practical implementations, ranging from stepper motor control to relay switching, and discover how this module serves as a linchpin in enabling precise and reliable functionality.

Embark on a journey of discovery as we delve deeper into the realm of the ULN2003 Driver Module, unraveling its intricacies and unlocking its full potential in your electronic ventures.

Functionality and Benefits of ULN2003 in Motor Control

When it comes to the realm of motor control, there exists a pivotal component that plays a crucial role in ensuring smooth operation and efficient functionality. This component, known for its adeptness in managing electrical currents and facilitating motor control, provides a myriad of advantages that enhance the overall performance of motor-driven systems.

The Essence of Motor Control Amplification

Embedded within the intricate network of motor control systems lies a key amplifier, discreet yet indispensable in its function. This amplifier, adept at bolstering signal strength and mitigating external interference, serves as the cornerstone for seamless motor operations. Its ability to fortify signals enables precise control over motor functions, ensuring optimal performance even in demanding operational conditions.

Enhancing Reliability and Efficiency

Within the spectrum of motor control lies the pursuit of reliability and efficiency, objectives that are meticulously pursued through the utilization of advanced components. Amidst this pursuit, the integration of a specialized driver chip emerges as a catalyst for heightened reliability and efficiency. By providing robust protection mechanisms and optimizing energy utilization, this driver chip elevates the performance metrics of motor-driven systems, thereby fostering a paradigm of reliability and efficiency.

In essence, the functionality and benefits attributed to this specialized component transcend mere amplification, extending towards the augmentation of reliability and efficiency within motor control systems.

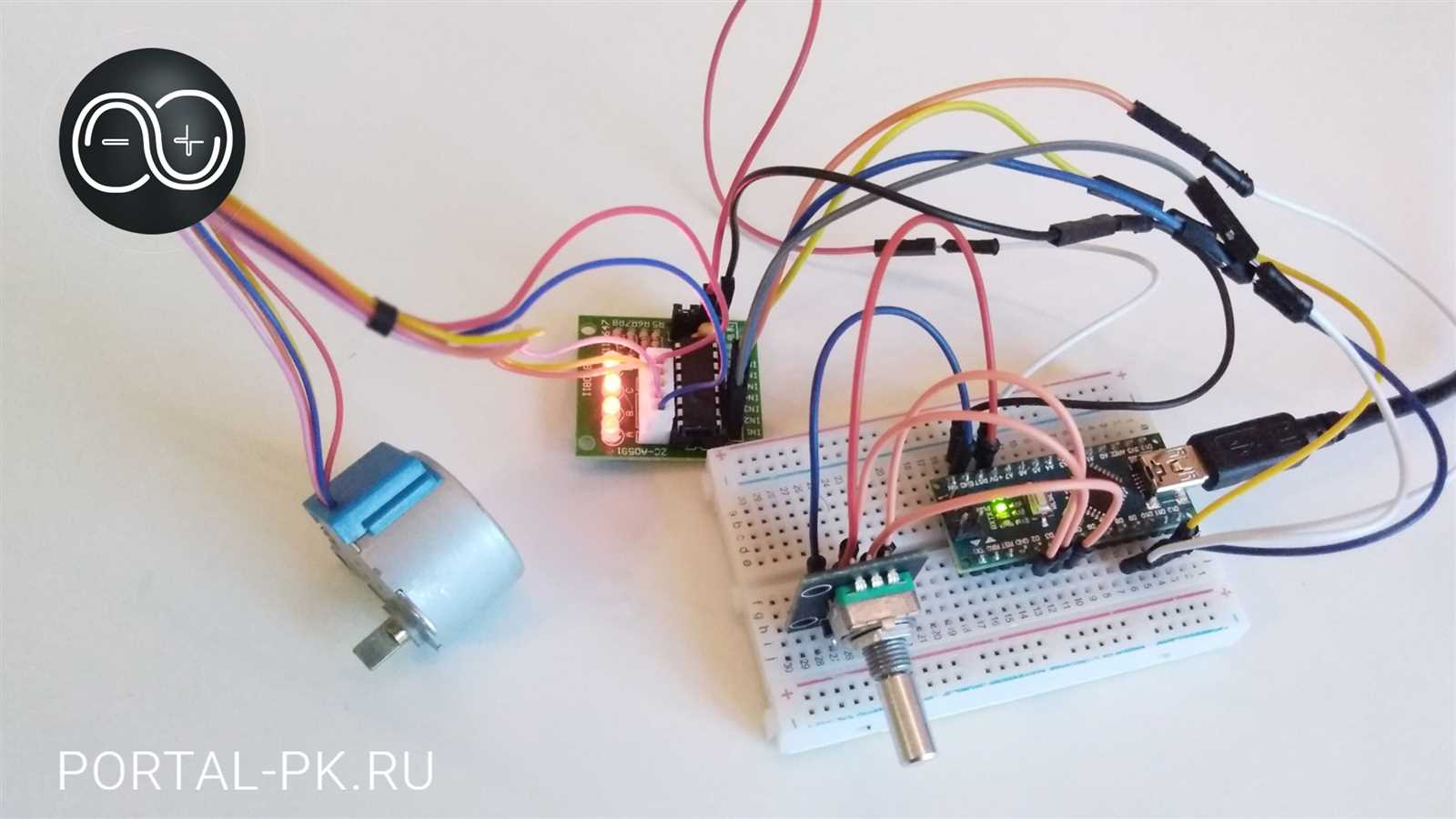

Integration Guide: 28BYJ-48 with ULN2003

In this section, we delve into the seamless amalgamation of a particular motor unit with a dedicated driver component. This guide elucidates the process of harmonizing motion control and power management, fostering a synergistic relationship between a specialized stepper motor model and its complementary driving circuitry. Through this integration, users can optimize performance, harnessing the full potential of their motion control system.

- Understanding the Stepper Motor: Exploring the intricacies of a precision motor unit designed for incremental motion, devoid of the need for position feedback sensors.

- Unlocking the Potential of Motor Control: Delving into the functionalities and capabilities of the driver module, facilitating precise control over motor movement and torque.

- Establishing Electrical Connections: Step-by-step instructions on how to establish a robust electrical interface between the stepper motor and the driver, ensuring seamless signal transmission and power delivery.

- Calibration and Optimization: Techniques for fine-tuning motor performance, including adjusting step resolution and optimizing current levels, to achieve desired motion characteristics.

- Practical Applications: Exemplary use cases showcasing the versatility and applicability of this integrated setup across various domains, from robotics to automation.

By integrating the unique attributes of the stepper motor with the tailored functionalities of the driver module, users can elevate their motion control systems to new heights of efficiency and precision. This guide serves as a compass, navigating through the intricacies of integration and empowering enthusiasts and professionals alike to unleash the full potential of their projects.