When it comes to selecting the ideal material for various applications, engineers and professionals are always in search of reliable and versatile options. In this regard, one material that has gained significant attention is 20crmnti. Understanding the specifications and characteristics of this material is crucial for making informed decisions and achieving desired outcomes in mechanical and engineering projects.

Imagine a scenario where you need a material that offers high strength, excellent toughness, and exceptional hardenability, all combined in one. 20crmnti, with its remarkable properties, has emerged as a preferred choice in such situations. Its unique combination of alloy elements and heat treatment capabilities enable it to meet the requirements of various industries, including automotive, machinery, and construction.

Strength, durability, and reliability are the intrinsic factors that define the quality of any material, and 20crmnti excels in all these aspects. With its exceptional tensile strength and impact resistance, this material ensures longevity and stability in the face of challenging conditions. Moreover, it exhibits excellent fatigue resistance, allowing it to withstand repetitive loading without compromising its structural integrity.

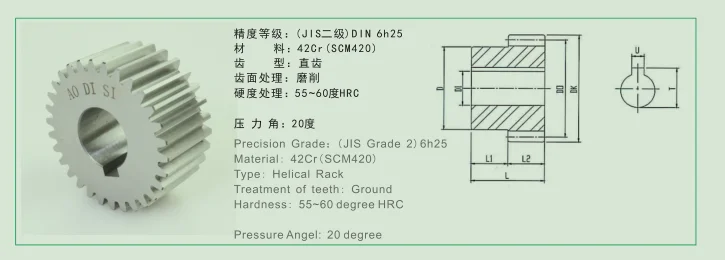

Additionally, 20crmnti possesses remarkable hardenability, which enables it to achieve high surface hardness and wear resistance. This makes it an ideal choice for applications where resistance to abrasion, friction, and surface wear is crucial. Its ability to retain strength and hardness even at elevated temperatures further enhances its credibility as a reliable and versatile material.

In this article, we will delve into the detailed specifications of 20crmnti, exploring its chemical composition, mechanical properties, heat treatment capabilities, and its wide range of applications. Understanding these aspects will equip engineers and professionals with valuable knowledge to utilize 20crmnti effectively in their projects, contributing to the overall success and efficiency of their endeavors.

What is a datasheet and why is it important?

A datasheet serves as a comprehensive and informative document that provides essential details about a particular product or component. It acts as a reference guide and serves multiple purposes for manufacturers, engineers, designers, and end-users alike.

A datasheet offers a wealth of information about the product, including its specifications, features, electrical characteristics, performance parameters, and application guidelines. It allows individuals to gain a deeper understanding of a product’s capabilities, limitations, and suitability for specific applications.

By providing detailed technical information, a datasheet helps in making informed decisions during the product selection process. It allows engineers and designers to compare different products and choose the one that best meets their requirements. Moreover, it helps in identifying any potential compatibility issues or limitations that may arise when integrating the product into a system.

A datasheet also plays a crucial role in ensuring proper installation, operation, and maintenance of the product. It provides instructions on how to correctly connect, configure, and operate the product, minimizing the risk of errors or damage. Additionally, it may include information on troubleshooting, safety precautions, and recommended operating conditions.

| Key Information Provided in a Datasheet |

|---|

| Product specifications |

| Electrical characteristics |

| Performance parameters |

| Application guidelines |

| Installation instructions |

| Operational guidelines |

| Maintenance instructions |

| Troubleshooting information |

| Safety precautions |

In conclusion, a datasheet is a vital tool that ensures effective product evaluation, selection, installation, and operation. It serves as a comprehensive reference guide that empowers individuals to make informed decisions, maximize product performance, and prevent any potential issues or risks associated with the use of the product.

Understanding the 20CrMnTi datasheet

In this section, we will explore the essential aspects of the technical documentation for the 20CrMnTi steel alloy. By delving into the details provided by the datasheet, we can gain a comprehensive understanding of its properties, applications, and potential uses in various industries.

Table of Contents:

- Chemical Composition

- Mechanical Properties

- Heat Treatment

- Applications

Chemical Composition

The chemical composition section of the 20CrMnTi datasheet presents the elemental constituents of this steel alloy. By analyzing the percentages of each element, such as carbon, manganese, and chromium, we can determine the alloy’s overall composition. Understanding the chemical composition is crucial for predicting the alloy’s mechanical properties and its compatibility with specific manufacturing processes.

Mechanical Properties

The mechanical properties section provides valuable information about the strength, hardness, and flexibility of the 20CrMnTi alloy. By examining its tensile strength, yield strength, and elongation, we can evaluate its performance in different environments and applications. Moreover, the hardness and impact resistance data allow engineers to determine the alloy’s suitability for specific structural or load-bearing purposes.

Heat Treatment

The heat treatment section outlines the recommended processes to optimize the 20CrMnTi alloy’s properties through controlled heating and cooling. This information is crucial for achieving the desired hardness, toughness, and microstructure of the material. By understanding the recommended heat treatment cycles, manufacturers can ensure the alloy’s performance and tailor it to meet specific requirements in various applications.

Applications

The applications section explores the industries and sectors where the 20CrMnTi alloy finds utility. It highlights its potential uses in automotive components, gears, shafts, and other machinery parts that require high strength, good fatigue resistance, and wear properties. By understanding the alloy’s applications, engineers can make informed decisions regarding its integration into specific designs or systems.

By comprehending the information presented in the 20CrMnTi datasheet, professionals can make informed decisions about utilizing this steel alloy for their respective projects. The datasheet serves as a valuable resource for understanding the composition, properties, heat treatment, and applications of the 20CrMnTi alloy, enabling accurate selection and optimization for various industrial needs.

Key specifications and characteristics of 20CrMnTi

In this section, we will explore the essential specifications and notable characteristics of the 20CrMnTi alloy. Understanding the key features of this material is crucial for various applications in engineering and manufacturing.

Composition:

The 20CrMnTi alloy is primarily composed of chromium, manganese, and titanium. This combination provides the material with unique properties, making it suitable for specific industrial purposes.

Strength and Hardness:

The 20CrMnTi alloy exhibits high strength and hardness, making it ideal for applications that require durability and resistance to wear and tear. Its robustness allows for increased load-bearing capacities and improved performance in challenging conditions.

Toughness and Versatility:

Along with its strength, 20CrMnTi possesses excellent toughness, enabling it to withstand impact and shock loads. This characteristic makes it versatile, as it can be used in a wide range of industries and applications that demand both strength and resilience.

Corrosion Resistance:

Thanks to the presence of chromium in its composition, 20CrMnTi offers good resistance against corrosion. This property makes it suitable for applications where exposure to harsh environmental conditions or corrosive substances is expected.

Heat Treatability:

The heat treatability of 20CrMnTi allows for easy modification of its mechanical properties through varying heat treatment processes. This flexibility makes it adaptable to different requirements, enhancing its usability in various engineering applications.

Applications:

Due to its excellent combination of properties, 20CrMnTi is commonly used in the manufacturing of gears, shafts, axles, and other high-stress components. Its durability, toughness, and resistance to wear and corrosion make it a preferred choice in automotive, aerospace, and heavy machinery industries.

In summary, the 20CrMnTi alloy offers a unique set of characteristics, including high strength, hardness, and toughness, along with good heat treatability and corrosion resistance. These features make it a versatile material suitable for various demanding applications.