In the realm of electronic components, there exists a blueprint, a technical map that guides the intricacies of modern devices. This document serves as a gateway, unveiling the inner workings and capabilities of a vital component. Delving into its intricacies requires deciphering a language of voltages, currents, and functionalities.

Exploration beckons as we embark on a journey through the labyrinth of circuits and specifications. This narrative unveils the essence of innovation, where each line and symbol holds the promise of transformative applications. Through the lens of technical expertise, we decode the essence of functionality, revealing the soul of electronic engineering.

Amidst the digital symphony, every component plays a crucial role, akin to a note in a grand composition. The component in focus possesses a myriad of attributes, each waiting to be uncovered and harnessed for creative endeavors. Understanding its nuances empowers engineers and enthusiasts alike to push the boundaries of possibility, breathing life into concepts and dreams.

Understanding the Specifications of the 17HS4401 Stepper Motor

Delving into the intricacies of motor documentation can be daunting, but it’s a crucial step in maximizing the performance and compatibility of your stepper motor. In this section, we’ll embark on a journey through the technical details and specifications of the 17HS4401 stepper motor, shedding light on its capabilities and potential applications.

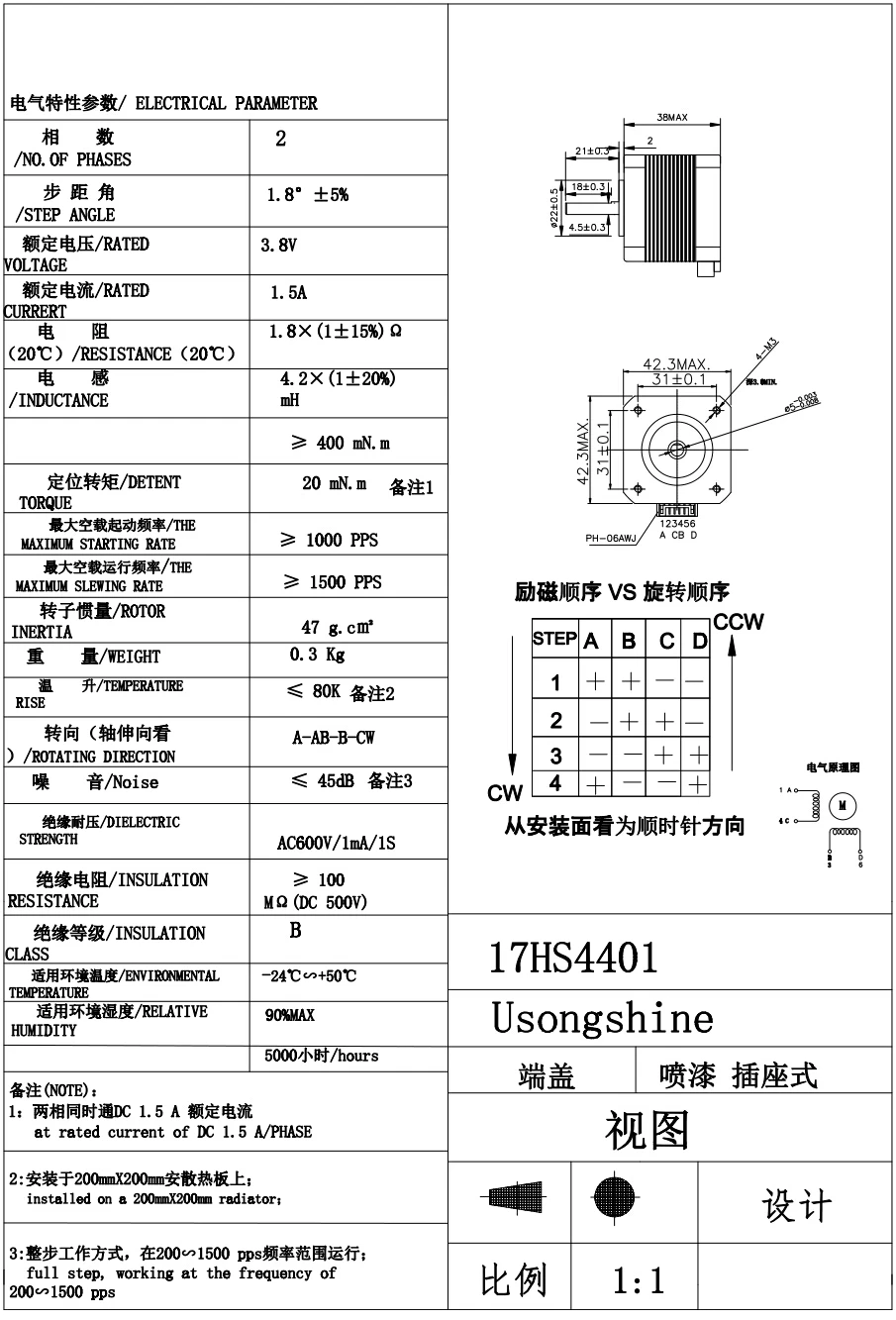

First and foremost, it’s essential to grasp the fundamental parameters that define the behavior and characteristics of the stepper motor. By dissecting the datasheet, we uncover insights into its operating voltage, current ratings, step angle, and holding torque. These specifications serve as the building blocks for understanding how the motor interacts with its environment and interfaces with external control systems.

Furthermore, a thorough examination of the performance curves provides invaluable information regarding the motor’s dynamic behavior under varying conditions. From torque-speed characteristics to temperature dependencies, these graphs offer a comprehensive view of the motor’s capabilities across different operating scenarios.

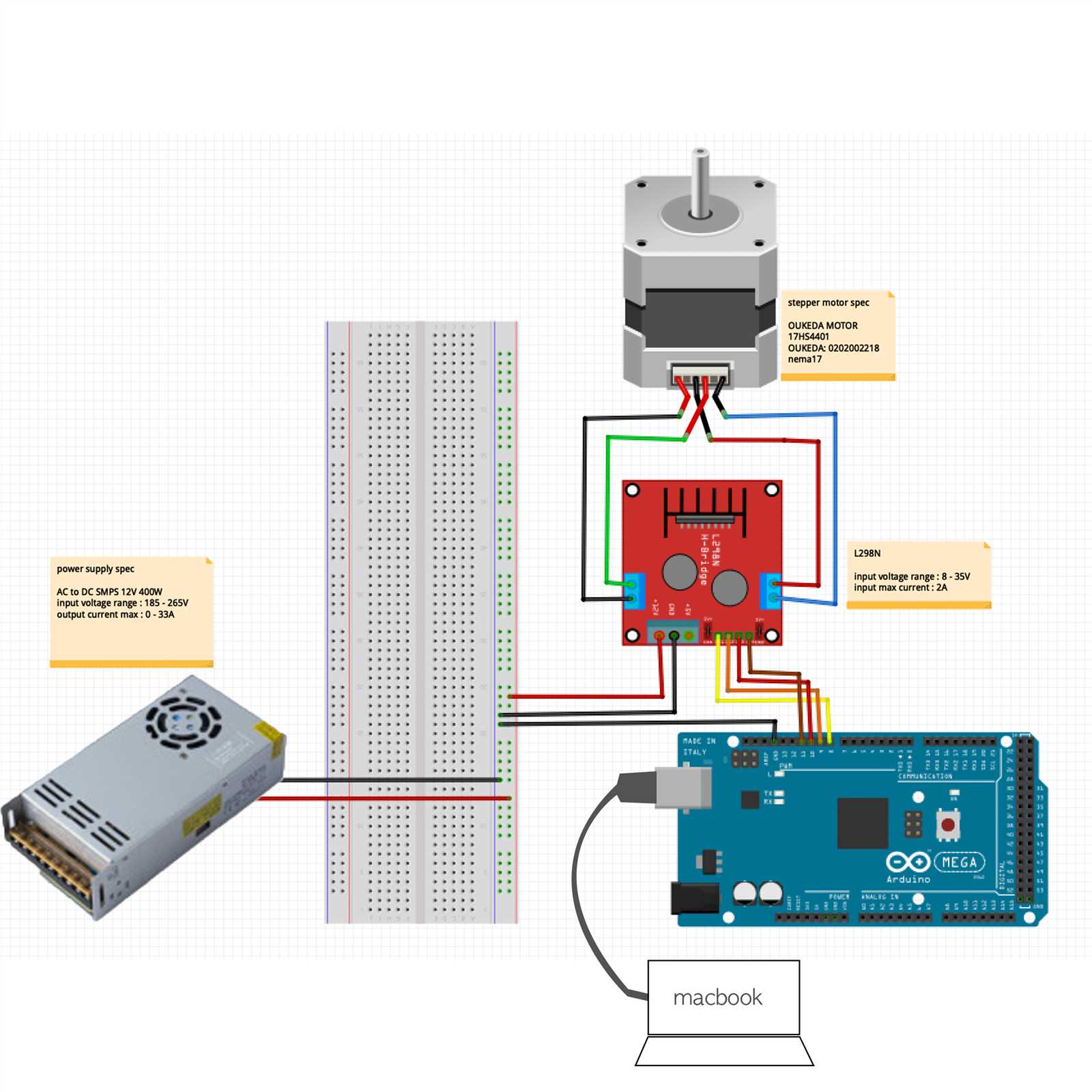

- Electrical Characteristics: Explore the voltage and current requirements, phase resistance, and inductance to ensure proper integration with the power supply and drive circuitry.

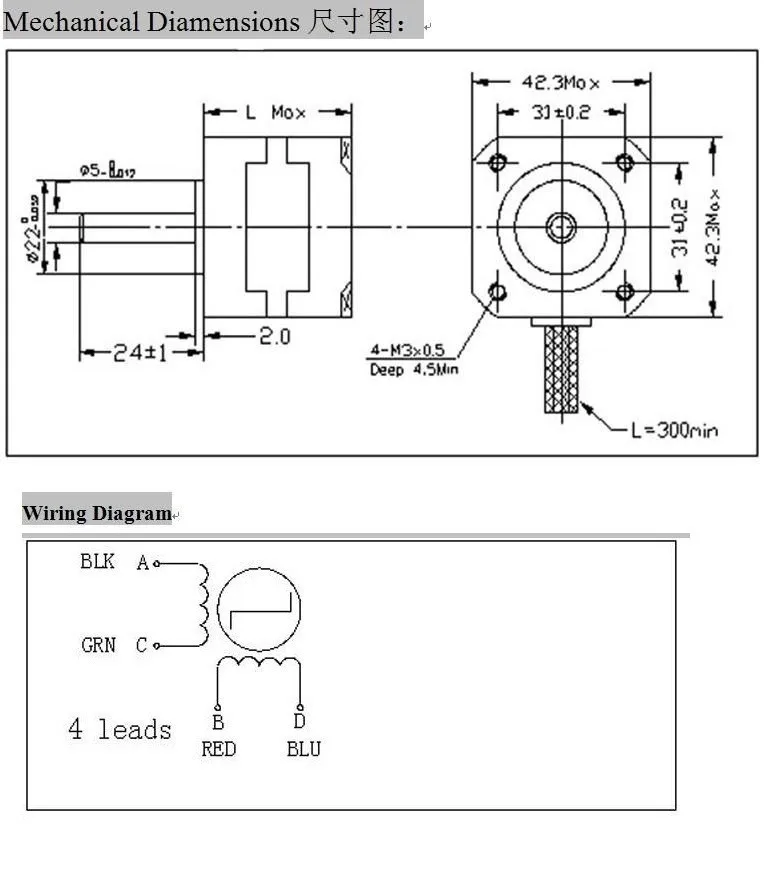

- Mechanical Specifications: Dive into details such as the motor’s physical dimensions, shaft configuration, and mounting options, facilitating seamless integration into your mechanical design.

- Environmental Considerations: Assess factors like temperature range, humidity tolerance, and vibration resistance to gauge the motor’s suitability for specific operating environments.

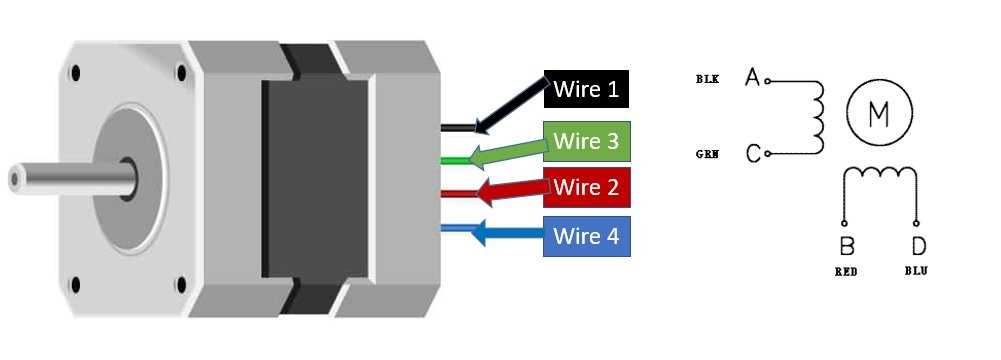

Additionally, understanding the motor’s wiring configuration and connector types is pivotal for establishing robust electrical connections and harnessing its full potential. Whether utilizing bipolar or unipolar drive schemes, deciphering the wiring diagram ensures correct setup and optimal performance.

In conclusion, comprehending the intricacies of the 17HS4401 stepper motor datasheet empowers engineers and enthusiasts alike to make informed decisions regarding motor selection, integration, and utilization. By unraveling the technical specifications and performance characteristics, we unlock the door to a world of precision motion control and automation possibilities.

Key Specifications and Performance Metrics

Overview of Technical Characteristics

In this section, we delve into the essential aspects and performance indicators of the component under discussion. We explore its fundamental attributes, providing insights into its functionality, capabilities, and operational parameters.

Critical Parameters and Operational Data

Here, we scrutinize the pivotal parameters and operational data relevant to the subject matter. We examine key metrics that define its performance, efficiency, and reliability, shedding light on its operational behavior and potential applications.

Performance Evaluation and Comparative Analysis

This segment offers a comprehensive evaluation of the component’s performance, juxtaposed with comparative analysis where applicable. Through systematic assessment, we assess its efficacy, performance benchmarks, and suitability for diverse scenarios, enabling informed decision-making.

Functional Characteristics and Application Scenarios

Delving into the functional characteristics and potential application scenarios, we explore how the component aligns with various use cases. We elucidate its capabilities, functionalities, and adaptability across different contexts, providing insights into its versatility and practical utility.

Reliability Metrics and Endurance Analysis

Here, we examine the reliability metrics and conduct an endurance analysis to gauge the component’s robustness and longevity under varying conditions. By scrutinizing its endurance, durability, and resilience, we ascertain its suitability for sustained operation in demanding environments.

Interpreting Electrical Characteristics and Operational Parameters

In the realm of electronic components, understanding the nuances of electrical characteristics and operational parameters is paramount. These factors delineate the performance, functionality, and compatibility of a given component within a broader system. Through diligent analysis and comprehension of these intricacies, engineers can optimize designs, ensure reliability, and mitigate risks.

Electrical characteristics encapsulate the fundamental properties governing the behavior of a component within an electrical circuit. These encompass a spectrum of metrics such as voltage ratings, current consumption, impedance, and frequency response. Mastery of these specifications enables engineers to discern how a component will interact with its environment, facilitating informed decision-making during the design phase.

Operating parameters, on the other hand, delineate the conditions under which a component functions optimally. These parameters encompass environmental factors like temperature, humidity, and pressure, alongside operational constraints such as duty cycle, load variations, and signal integrity requirements. Grasping the intricacies of these parameters is essential for ensuring the reliability and longevity of electronic systems across diverse application scenarios.

By delving into the interpretation of these electrical characteristics and operational parameters, engineers can unlock insights into a component’s behavior and performance profile. This nuanced understanding serves as a cornerstone for effective system design, troubleshooting, and optimization, fostering innovation and advancement in the field of electronics.

Practical Application Tips and Troubleshooting Guidelines

In this section, we delve into practical insights and strategies for effectively applying the components in question and addressing common challenges that may arise during their utilization. We offer actionable tips to optimize performance and troubleshoot issues efficiently.

Optimizing Component Performance

When integrating components into your system, it’s essential to consider various factors that can affect their performance. Paying attention to voltage requirements, current limitations, and compatibility with other elements in the circuit can significantly impact the overall functionality. Additionally, ensuring proper thermal management and adequate cooling mechanisms can prevent overheating, thereby extending the lifespan of the components.

Troubleshooting Strategies

Despite careful planning and implementation, encountering challenges is not uncommon in electronics projects. When faced with issues such as erratic behavior or component failure, systematic troubleshooting is crucial. Start by inspecting connections and checking for loose wires or damaged components. Utilizing diagnostic tools like multimeters can help identify faulty elements accurately. Furthermore, referring to manufacturer documentation and seeking support from online communities or forums can provide valuable insights and solutions to overcome obstacles.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Intermittent Motor Operation | Loose wiring connections | Inspect and tighten all connections; replace damaged wires if necessary. |

| Overheating of Driver Module | Inadequate cooling | Improve ventilation and consider adding heatsinks to dissipate heat effectively. |

| Unresponsive Motor | Faulty driver module | Test driver module with a known working motor; replace if malfunctioning. |