In the world of metallurgy and material science, there exists an extraordinary alloy that has captivated the attention of researchers and engineers alike. Its unique combination of strength, corrosion resistance, and machinability has made it a standout performer in various industries.

This alloy, commonly referred to as “PH,” boasts an impressive set of characteristics that set it apart from its counterparts. PH is an abbreviation for “precipitation hardening,” a process that enhances the alloy’s strength through controlled heat treatment. This process imparts exceptional toughness and durability, making PH a preferred choice for demanding applications.

One particular variant of this remarkable alloy, commonly known as “17-4 PH,” has garnered significant interest. This variant, characterized by its composition of chromium, nickel, and copper, offers exceptional corrosion resistance, superior to many other stainless steel alloys. Furthermore, it exhibits impressive tensile strength while maintaining good formability, making it an ideal choice for industries where both strength and versatility are paramount.

The 17-4 PH alloy finds wide-ranging applications in industries such as aerospace, defense, oil and gas, and biomedical engineering. Its resistance to both general corrosion and stress corrosion cracking makes it highly sought after, particularly in environments where exposure to harsh conditions is inevitable. Additionally, its compatibility with various fabrication methods further amplifies its appeal.

In this article, we delve into the comprehensive datasheet of the 17-4 PH alloy. We explore its detailed chemical composition, mechanical properties, and its suitability for different applications. Join us as we uncover the secrets behind this alloy’s exceptional performance and discover why it has become a favorite choice among engineers and designers worldwide.

What is 17-4 PH?

The material known as 17-4 PH is a type of precipitation-hardening stainless steel alloy. It is widely used in various industries due to its unique combination of strength, corrosion resistance, and machinability. This alloy possesses excellent mechanical properties, making it suitable for applications that require high strength and toughness.

- 1. Precipitation-hardening stainless steel

- 2. Unique combination of strength, corrosion resistance, and machinability

- 3. Widely used in various industries

- 4. Excellent mechanical properties

- 5. Suitable for applications requiring high strength and toughness

The 17-4 PH alloy derives its name from its composition, which consists of approximately 17% chromium and 4% nickel, as well as small amounts of copper and other elements. These elements contribute to the alloy’s ability to undergo precipitation hardening, a heat treatment process that enhances its strength and durability.

Due to its corrosion resistance properties, this alloy is commonly used in applications where it may be exposed to harsh environments, such as marine equipment, aerospace components, and chemical processing equipment. Additionally, its machinability allows for the production of intricate parts and components with ease.

Overall, 17-4 PH is a versatile stainless steel alloy that offers a combination of properties suitable for a wide range of applications. Its unique composition and mechanical characteristics make it a valuable material in various industries.

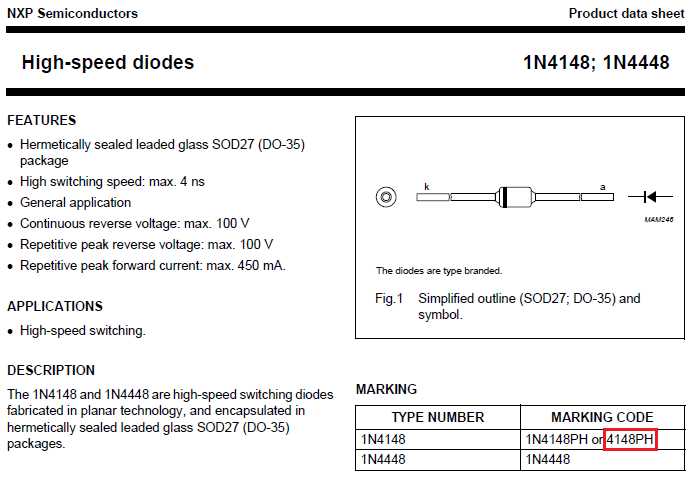

Chemical Composition and Mechanical Properties

In this section, we will discuss the chemical composition and mechanical properties of an alloy with the designation 17-4 ph. Understanding the composition and properties of this alloy is essential for a variety of applications in different industries, including aerospace, oil and gas, and automotive.

Chemical Composition

The alloy 17-4 ph is composed of a combination of elements that contribute to its unique properties. It primarily consists of iron, chromium, nickel, and copper, with smaller amounts of manganese, silicon, and niobium. These elements work together to enhance the alloy’s strength, corrosion resistance, and toughness.

Mechanical Properties

The mechanical properties of 17-4 ph are crucial in determining its suitability for specific applications. This alloy exhibits excellent strength and hardness, making it ideal for demanding environments. It also demonstrates good ductility and toughness, allowing for deformation without sacrificing its integrity.

Furthermore, 17-4 ph shows remarkable corrosion resistance, particularly in various harsh conditions, such as high temperatures and exposure to corrosive chemicals. This property makes it a reliable choice for applications where resistance to corrosion is essential.

In conclusion, a thorough understanding of the chemical composition and mechanical properties of 17-4 ph is vital in evaluating its performance and suitability for various industrial applications. The combination of elements in this alloy contributes to its excellent strength, corrosion resistance, and toughness, which make it a reliable material for demanding environments.

Applications and Uses

The versatility and properties of 17-4 PH make it a valuable material in various applications across industries and sectors. Its exceptional strength, corrosion resistance, and high machinability make it a preferred choice for a wide range of uses.

Mechanical Components

17-4 PH is commonly used in the manufacturing of mechanical components. Its high hardness and strength make it ideal for applications where toughness and durability are required. It is often used in the production of gears, shafts, valves, and fasteners.

Aerospace and Defense

The aerospace and defense industry extensively uses 17-4 PH for its critical applications. This alloy’s ability to withstand extreme temperatures, as well as its resistance to corrosion and fatigue, make it suitable for aircraft components, missile systems, and weapon parts.

Additionally, 17-4 PH is utilized in the manufacturing of firearm components, such as barrels and receivers, due to its strength and resistance to erosion.

Outside of these specific applications, 17-4 PH finds use in a wide variety of industries, including oil and gas, chemical processing, medical devices, and automotive. Its combination of mechanical properties and corrosion resistance offers countless possibilities for innovative designs and reliable performance in diverse fields.